Method for preparing okra pulp, frozen drink and method for preparing frozen drink

A frozen drink and freezing technology, which is applied in the direction of food ingredients as a taste improver, food science, etc., can solve problems that need to be improved, and achieve the effects of protecting color and nutrients, reducing green taste, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] In this example, ice cream was prepared as follows:

[0056] Raw materials: white sugar: 125kg, fructose syrup: 30kg, skimmed milk powder: 110kg, cream: 100kg, anhydrous butter: 40kg, coconut oil: 30kg, okra pulp: 80kg, locust bean gum: 1.5kg, xanthan gum : 0.4kg, carrageenan: 0.2kg, glyceryl monostearate: 1.5kg, apple flavor: 1.0kg, lemon yellow pigment: 10g, bright blue pigment: 1g

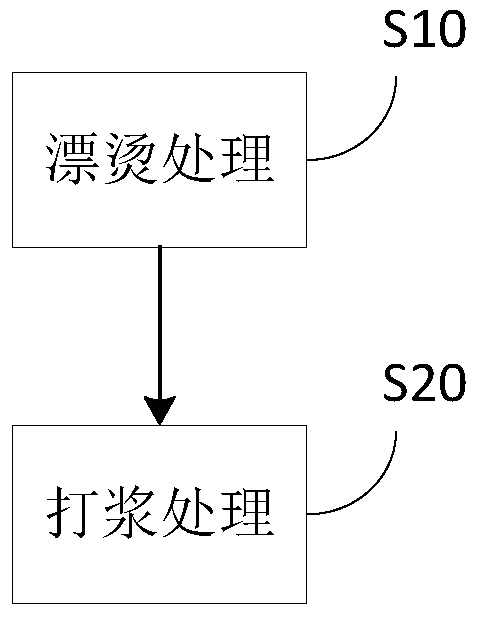

[0057] Okra pulp is prepared by the following steps:

[0058] (1-1) Put saturated water vapor at 4kg / cm 2 Heated to 140 degrees under the pressure of 100kg okra, then blanched for 25 seconds;

[0059] (1-2) Thinning the okra obtained in step (1-1) in a high-speed shear pump to obtain okra pulp.

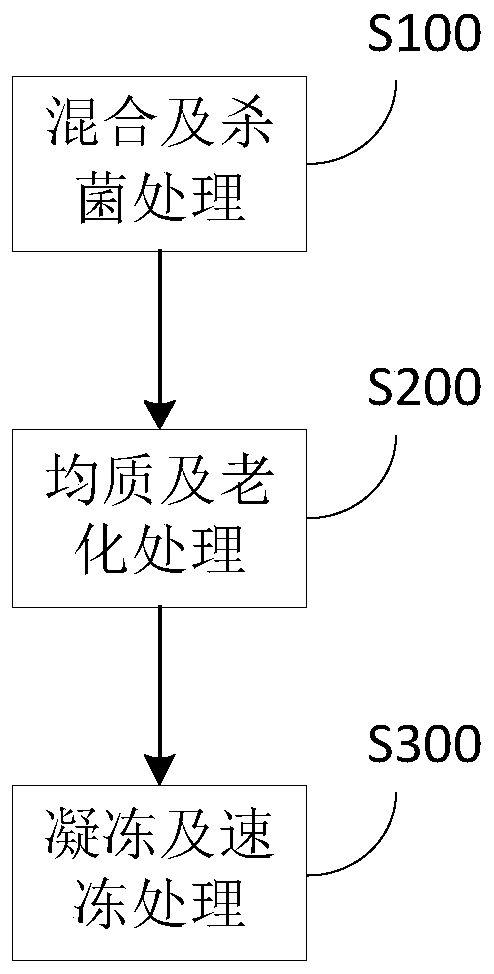

[0060] To prepare the ice cream:

[0061] (2-1) White granulated sugar, fructose syrup, skimmed milk powder, cream, anhydrous butter, coconut oil, okra pulp, locust bean gum, xanthan gum, carrageenan, and glyceryl monostearate are mixed;

[0062] (2-2) Pasteurize the mixture obtained in step...

Embodiment 2

[0069] Prepare ice cream according to the method of embodiment 1, difference is:

[0070] Raw materials: white sugar: 130kg, malt syrup: 60kg, whole milk powder: 80kg, coconut oil: 80kg, okra pulp: 70kg, sodium carboxymethylcellulose: 1.5kg, guar gum: 1.4kg, locust bean gum : 0.3kg, glyceryl monostearate: 1.8kg, apple essence: 1.0kg, lemon yellow pigment: 10g, bright blue pigment: 1g;

[0071] Thus, the total solid content in the obtained ice cream: 34.5%, protein content: 2.2%, fat content: 10.2%.

Embodiment 3

[0073] Prepare snow mud according to the method for embodiment 1, difference is:

[0074] Raw materials: white sugar: 150kg, fructose syrup: 80kg, maltose syrup: 60kg, skimmed milk powder: 10kg, coconut oil: 10kg, okra pulp: 150kg, xanthan gum: 1.2kg, locust bean gum: 1.2kg, carrageenan : 0.4kg, glyceryl monostearate: 1.0kg, citric acid: 1.6kg, lactic acid: 1.0kg, malic acid: 0.5kg, apple essence: 1.0kg, lemon yellow pigment: 5g, bright blue pigment: 1g;

[0075] Thus, the total solid content in the obtained slush is 29.7%, and the total sugar content (calculated as sucrose): 25.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com