System for treating coke oven exhausted contaminants

A coke oven and sewage technology, applied in the direction of gas treatment, use of liquid separation agent, membrane technology, etc., can solve the problem of high dust, high sulfur coal combustion that is not fully adapted to the national conditions, unstable flue gas emission from desulfurization towers, gas-liquid transmission In order to avoid problems such as poor mass exchange effect, stable pollution control effect, low noise and small equipment volume can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation plan

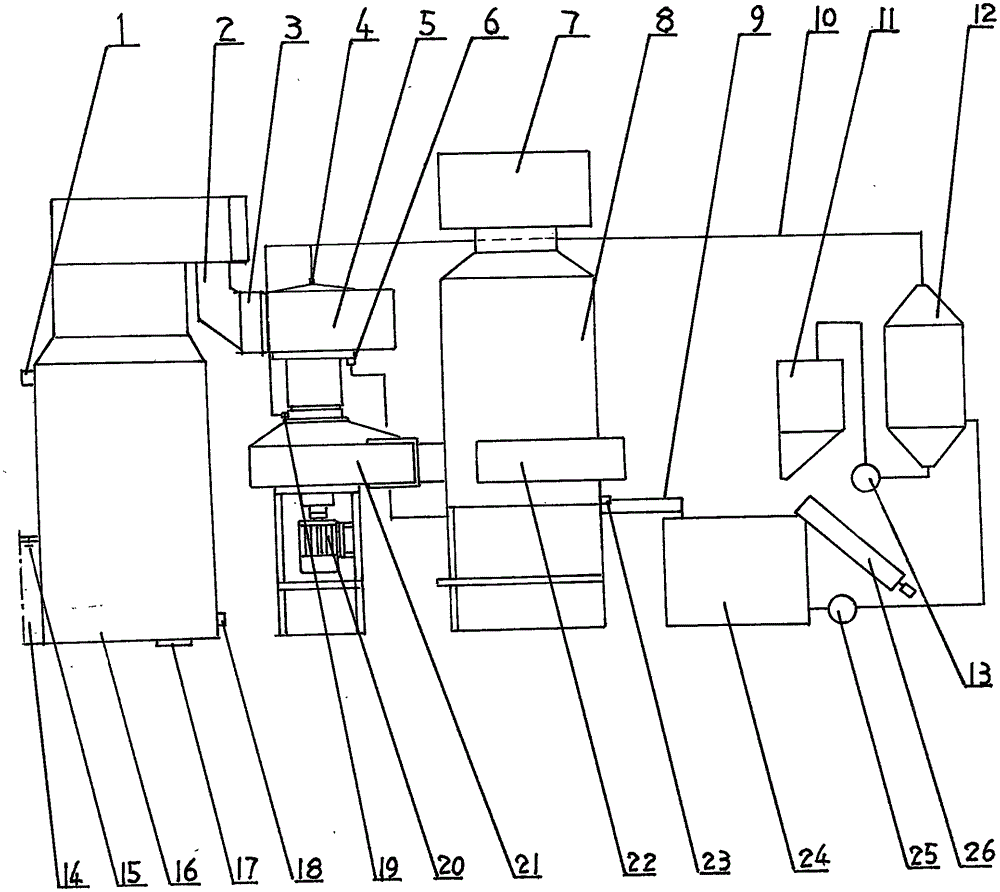

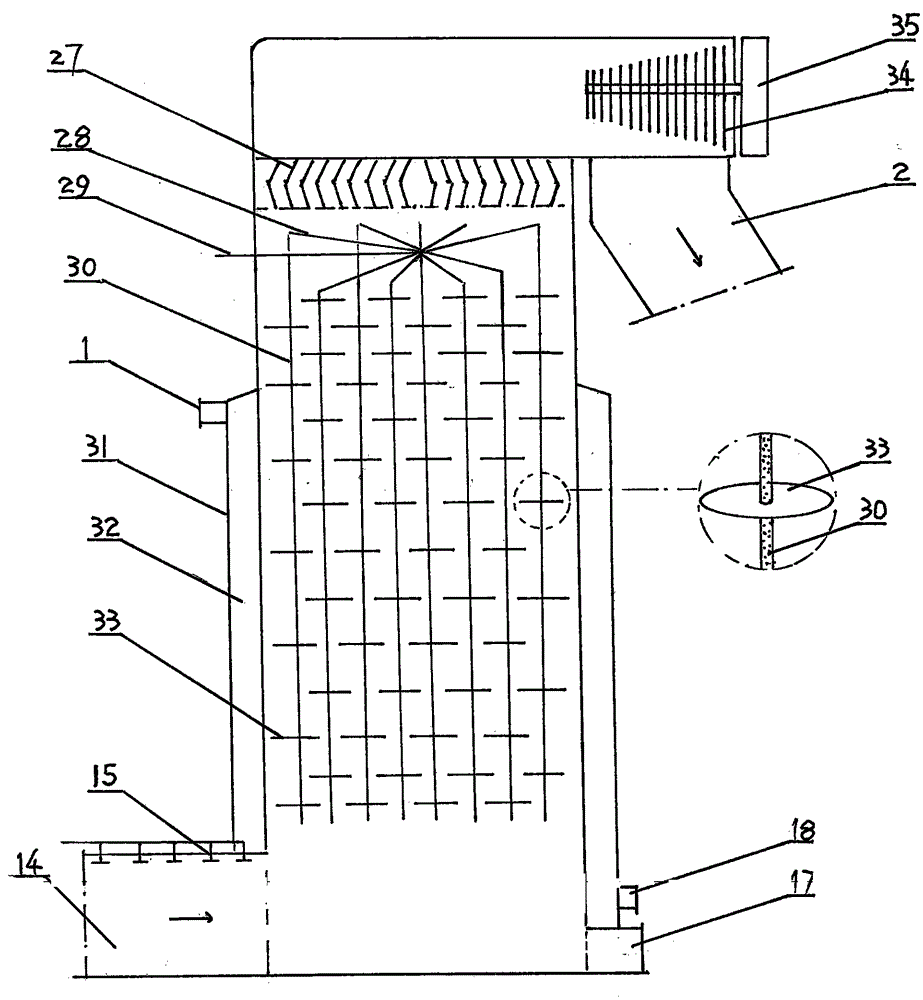

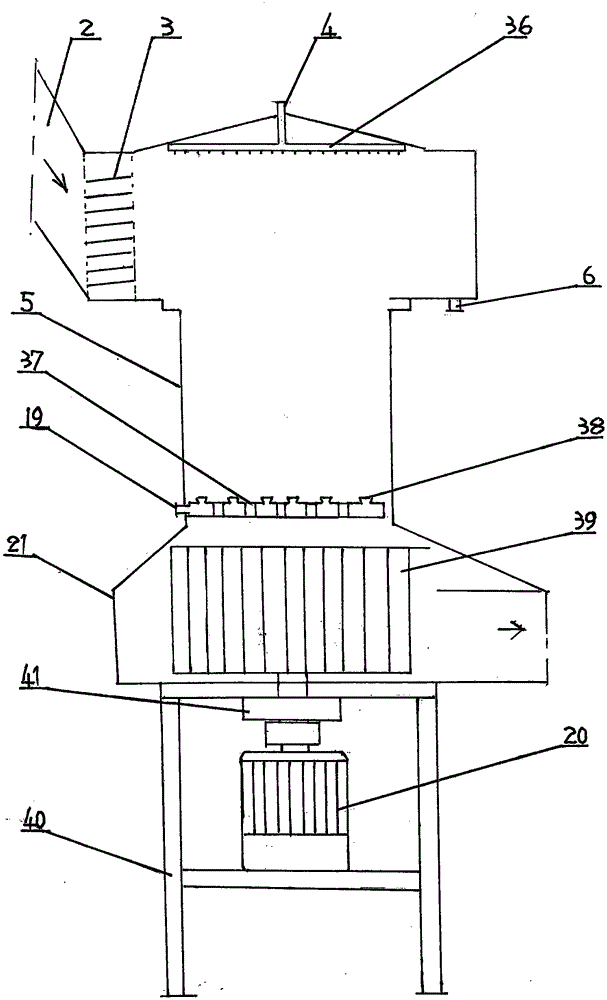

[0022] Such as Figure 1 to Figure 4 As shown, a coke oven discharge sewage treatment system includes a percolator 12 , a water tank 24 , a dehydration tank 8 , a filter paste box 11 and a diaphragm pump 13 . The upper end of the flue 14 communicating with the smoke inlet of the smoke washing tower is provided with a row of atomizing nozzles 15 for spraying hydrogen liquid, and the smoke inlet communicates with the inner lower end of the smoke washing tower. The smoke outlet 2 of the smoke washing tower communicates with the inner upper end of the smoke washer 5 . The inner lower end of the smoke washer communicates with the inner upper end of the gas washer 21 . The gas outlet of the scrubber communicates with the dehydration tank 8 through the 8-shaped cyclone pipe 22, and the upper end of the dehydration tank is a smoke exhaust outlet. The upper water outlet of the percolator communicates with the upper water inlet 4 of the smoke was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com