A kind of preparation method of aluminum silicate fiber

A technology of aluminum silicate fiber and clinker, used in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of large heat loss, large gap between raw materials, and small heating area of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The invention provides a kind of preparation method of aluminum silicate fiber, comprises the following steps:

[0020] The raw material clinker of aluminum silicate fiber is crushed, melted and centrifuged in turn to obtain aluminum silicate fiber;

[0021] The particle size gradation of the pulverization is as follows: the mass percent content of 2-5mm particle diameter is 50-99%; the mass percent content of 0-2mm particle diameter is 1-50%.

[0022] The preparation method in the present invention has fast raw material melting rate and low energy consumption.

[0023] In the present invention, the raw material clinker of the aluminum silicate fiber preferably includes one or more of burnt gemstone clinker, coal gangue clinker, kaolinite clinker and bauxite clinker, wherein, burnt gemstone clinker In clinker, Al 2 o 3 : 40-50%, Al 2 o 3 +SiO2 2 ≥97%, Fe 2 o 3 2 o 3 : 40-50%, Al 2 o 3 +SiO2 2 ≥97%, Fe 2 o 3 2 o 3 : 20-40%, Al 2 o 3 +SiO2 2 ≥96%, Fe 2 ...

Embodiment 1

[0040] 80 parts by weight of coal gangue clinker are processed and crushed until particle diameters of 2 to 5 mm account for 70%, and those within 2 mm account for 30%; It accounts for 30% within; then, it is evenly mixed by a mixer, and melted at a temperature of 2100 ° C, and the formed molten liquid is centrifugally spun to prepare aluminum silicate fibers. In the obtained aluminum silicate fiber, Al 2 o 3 39-42%, Al 2 o 3 +SiO2 2 ≥98%, Fe 2 o 3 <1%.

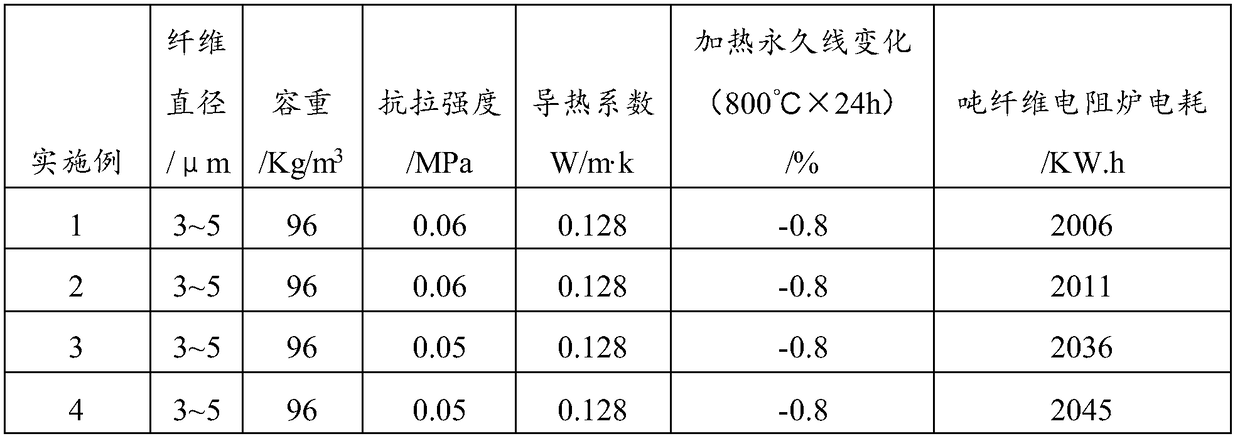

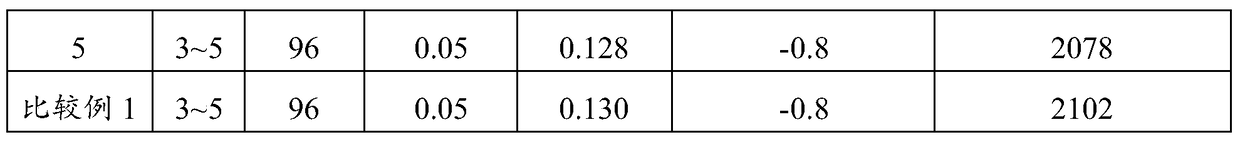

[0041] The present invention has tested the fiber diameter, tensile strength, thermal conductivity and heating permanent line change of the aluminum silicate fiber in this embodiment respectively, and the results are shown in Table 1, and Table 1 is Examples 1 to 5 of the present invention and Comparative Example 1 The performance parameters of the obtained aluminum silicate fiber.

Embodiment 2

[0043] 80 parts by weight of coal gangue clinker are processed and crushed until the particle size is 2-5mm, accounting for 60%, and 20% of the kaolinite clinker is processed and crushed until the particle size is 2-5mm, accounting for 60%. 40% within 2mm; after that, the material is evenly mixed by a mixer, and melted at a temperature of 2100 ° C, and the formed melt is centrifugally spun to prepare aluminum silicate fibers. In the obtained aluminum silicate fiber, Al 2 o 3 39-42%, Al 2 o 3 +SiO2 2 ≥98%, Fe 2 o 3 <1%.

[0044] The present invention has tested the fiber diameter, tensile strength, thermal conductivity and heating permanent line change of the aluminum silicate fiber in this embodiment respectively, and the results are shown in Table 1, and Table 1 is Examples 1 to 5 of the present invention and Comparative Example 1 The performance parameters of the obtained aluminum silicate fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com