High strength nanometer self-cleaning glass and preparation method thereof

A nano-self-cleaning, high-strength technology, applied in the field of glass materials, can solve problems such as damage, high cost, and difficult cleaning, and achieve the effects of simple preparation methods, broad application prospects, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0026] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0027] All raw materials used in the present invention are known commercial products.

Embodiment 1

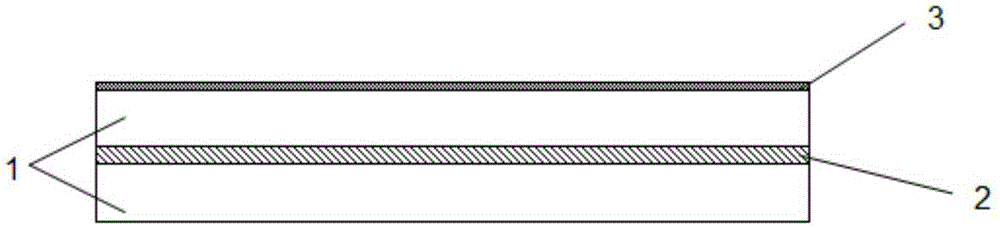

[0029] This embodiment provides a kind of high-strength nano self-cleaning glass, such as figure 1 As shown, its structure includes laminated glass and a titanium dioxide nano-coating 3 coated on one of the outer surfaces of the laminated glass; the laminated glass consists of two layers of tempered glass 1 and two layers of tempered glass 1 An EVA film layer 2 is formed between them.

[0030] Among them, the total thickness of the high-strength nano-self-cleaning glass is about 10cm, and the thicknesses of the tempered glass layer, EVA film layer and titanium dioxide nano-coating are 5cm, 0.76mm, and 0.08μm, respectively.

Embodiment 2

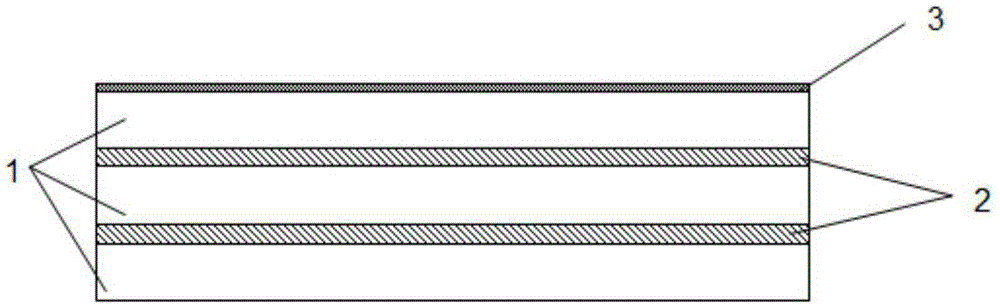

[0032] This embodiment provides a kind of high-strength nano self-cleaning glass, such as figure 2 As shown, its structure includes laminated glass and a titanium dioxide nano-coating 3 coated on one of the outer surfaces of the laminated glass; the laminated glass is composed of three layers of tempered glass 1 and respectively sandwiched between adjacent tempered glass 1 EVA film layer 2 forming

[0033] Among them, the total thickness of the high-strength nano-self-cleaning glass is about 15cm, and the thicknesses of the tempered glass layer, EVA film layer and titanium dioxide nano-coating are 5cm, 1.52mm, and 1μm, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com