A kind of halogen-free flame-retardant resin and preparation method thereof

A flame retardant resin and flame retardant technology, which is applied in the field of halogen-free flame retardant resin and its preparation, can solve the problems of decreased mechanical properties and large amount of flame retardant, and achieve good mechanical properties, good flame retardancy and stability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

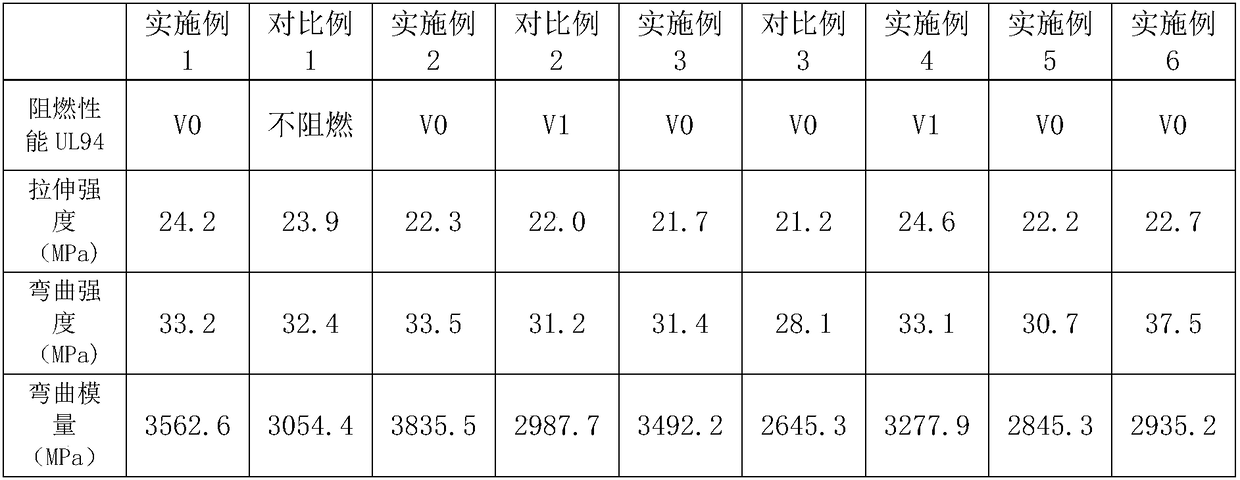

Examples

Embodiment 1

[0026] A halogen-free flame-retardant polypropylene resin, which contains components and their weight percentages: 67.95% of polypropylene, 25% of intumescent flame retardant, 5% of EPDM toughening agent, 0.05% of cross-linking agent DCP, cross-linking aid Joint agent methyl methacrylate 0.5%, antioxidant 0.5%, dispersive lubricant EBS (N,N'-ethylene bisstearamide) 0.5%, dispersive lubricant PE wax 0.5%; wherein, the expansion resistance The fuel is composed of ammonium polyphosphate, melamine and pentaerythritol, and the weight ratio of ammonium polyphosphate, melamine and pentaerythritol is 3:1:0.5.

[0027] The halogen-free flame-retardant polypropylene resin is prepared by the following steps:

[0028] Step A: first mix EPDM in a double-roll mill and cover the rolls, then add intumescent flame retardant, cross-linking agent and cross-linking auxiliary agent to mix evenly, then cut the material and cut it into granules for later use.

[0029] Step B: Mix the kneaded flame ...

Embodiment 2

[0032]A halogen-free flame-retardant polypropylene resin, which contains components and their weight percentages: polypropylene 62.95%, intumescent flame retardant 30%, butadiene rubber 5%, cross-linking agent DCP 0.05%, cross-linking assistant Agent ethyl methacrylate 0.5%, antioxidant 0.5%, dispersion lubricant EBS 0.5%, dispersion lubricant PE wax 0.5%. Wherein, the composition of the intumescent flame retardant is silane-coated ammonium polyphosphate, melamine pyrophosphate and dipentaerythritol, and the weight ratio of silane-coated ammonium polyphosphate, melamine pyrophosphate and dipentaerythritol is 2:1:0.8.

[0033] The halogen-free flame-retardant polypropylene resin is prepared by the following steps:

[0034] Step A: first knead the butadiene rubber in a two-roll mill and cover the rolls, then add intumescent flame retardant, cross-linking agent and cross-linking auxiliary agent and knead evenly, then cut the material and cut it into granules for later use.

[00...

Embodiment 3

[0038] A halogen-free flame-retardant polypropylene resin, which contains components and their weight percentages: polypropylene 57.95%, intumescent flame retardant 35%, SEBS 5%, cross-linking agent DCP 0.05%, auxiliary cross-linking agent acrylic acid Ethyl ester 0.5%, antioxidant 0.5%, dispersing lubricant EBS 0.5%, dispersing lubricant liquid paraffin 0.5%. Wherein, the composition of the intumescent flame retardant is ammonium polyphosphate coated with melamine resin, melamine polyphosphate and tripentaerythritol, and the weight ratio of the three is 4:1:0.3.

[0039] The halogen-free flame-retardant polypropylene resin is prepared by the following steps:

[0040] Step A: First, mix the natural rubber in a two-roll mill and cover the rolls, then add intumescent flame retardant, cross-linking agent and cross-linking auxiliary agent and mix evenly, then cut the material and cut it into granules for later use.

[0041] Step B: Mix the kneaded flame retardant masterbatch with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com