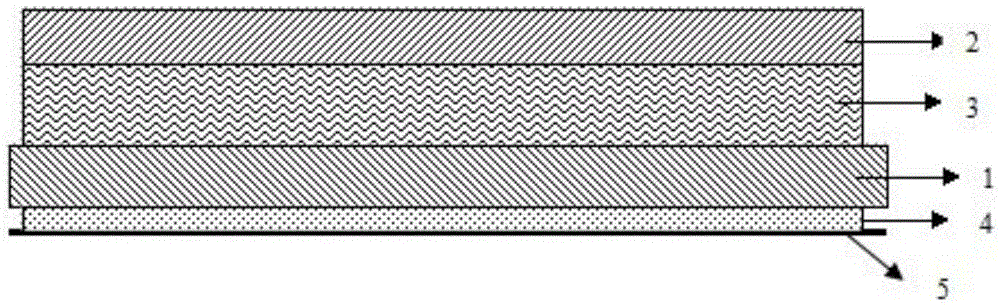

Multi-layer structure protective film and preparation method and application thereof

A multi-layer structure and protective film technology, which is applied in the field of film materials, can solve the problems of debris at the corners, human body injury, scratching the skin, etc., and achieve the effect of excellent performance, not easy to break, and good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

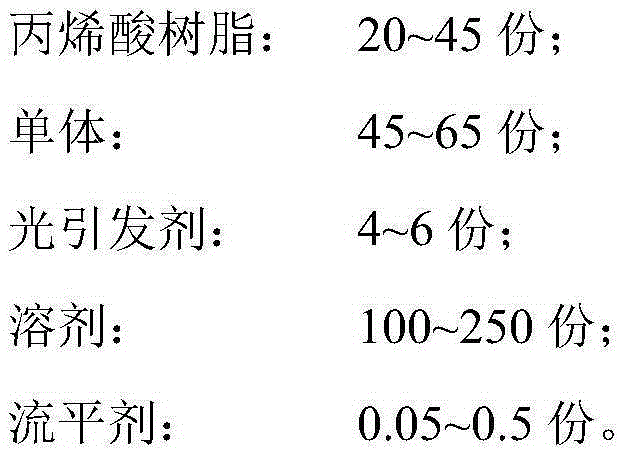

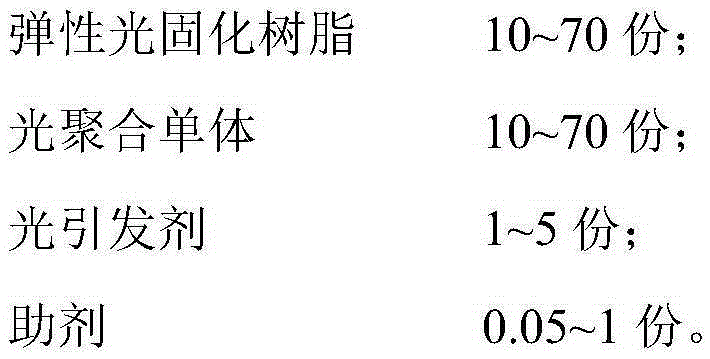

[0050] The buffer layer coating composition comprises the following components in parts by weight:

[0051]

[0052]

[0053] Wherein, the elastic photocurable resin is a trifunctional acrylate unsaturated polymer having both soft and hard segment structures.

[0054] The trifunctional acrylate unsaturated polymer is prepared by a Michael addition reaction in a one-pot method at room temperature, and the preparation method includes the following steps:

[0055] At room temperature, using ethyl acetate as a solvent, react 2-phenoxyethyl acrylate with 1,6-hexanediamine. After the reaction is complete, add polyethylene glycol-200 diacrylate to the reaction system Carry out the reaction, after the reaction is over, add trimethylolpropane triacrylate to the reaction system for reaction; after the reaction is over, add polyethylene glycol-200 diacrylate to the reaction system for reaction, after the reaction is over , precipitated with n-hexane, and then vacuum-dried to obtai...

Embodiment 2

[0059] The buffer layer coating composition comprises the following components in parts by weight:

[0060]

[0061] Wherein, the elastic photocurable resin is a trifunctional acrylate unsaturated polymer having both soft and hard segment structures.

[0062] As a preferred solution, the trifunctional acrylate unsaturated polymer is prepared by using a Michael addition reaction in a one-pot method at room temperature, and the preparation method includes the following steps:

[0063] At room temperature, using ethyl acetate as a solvent, react 2-phenoxyethyl acrylate with 1,6-hexanediamine. After the reaction is complete, add polyethylene glycol-200 diacrylate to the reaction system Carry out the reaction, after the reaction is over, add trimethylolpropane triacrylate to the reaction system for reaction; after the reaction is over, add polyethylene glycol-200 diacrylate to the reaction system for reaction, after the reaction is over , precipitated with n-hexane, and then va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com