A coke slag conditioning and tempering decoking agent suitable for high-sodium coal, its preparation method and application

A technology of decoking agent and high-sodium coal, which is applied in the direction of fuel additives, petroleum industry, solid fuel, etc., and can solve problems such as poor and effective utilization of coal resources, restrictions on the development of coal power industry, and coke cleaning accidents caused by boiler shutdown , to avoid low-temperature eutectic, reduce the formation of alkali metal vapor, and reduce the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A coke slag conditioning type decoking agent suitable for high-sodium coal. The raw material components of the decoking agent and their weight percentages are as follows:

[0042] Magnesium oxide 62%, kaolin 26%, bentonite 5%, copper nitrate 1%, potassium permanganate 2%, nickel chloride 2%, dispersant 2%.

[0043] The decoking agent according to the embodiment of the present invention is directly and uniformly mixed with Zhundong coal at a ratio of 5‰, and is burned in the test boiler, and the combustion temperature is stable, and the sample is taken with a sampling tube. Compared with the sampling of Zhundong coal in the test boiler under the same working conditions without adding the decoking agent pointed out by the present invention, the pollution and coking quality per unit time and internal unit area are less than those without the addition of the decoking agent pointed out by the present invention. The time is reduced by more than 35%, the ash collection efficie...

Embodiment 2

[0045] A coke slag conditioning type decoking agent suitable for high-sodium coal. The raw material components of the decoking agent and their weight percentages are as follows:

[0046] Magnesium hydroxide 87%, kaolin 10%, bentonite 0%, copper sulfate 1.5%, manganese oxide 2%, nickel nitrate 0.5%, dispersant 2%.

[0047] The decoking agent of this embodiment is sent into the injection device through the frequency conversion screw feeder, and then sprayed into the combustion area in the furnace by the injection device.

[0048] The specific application method is as follows:

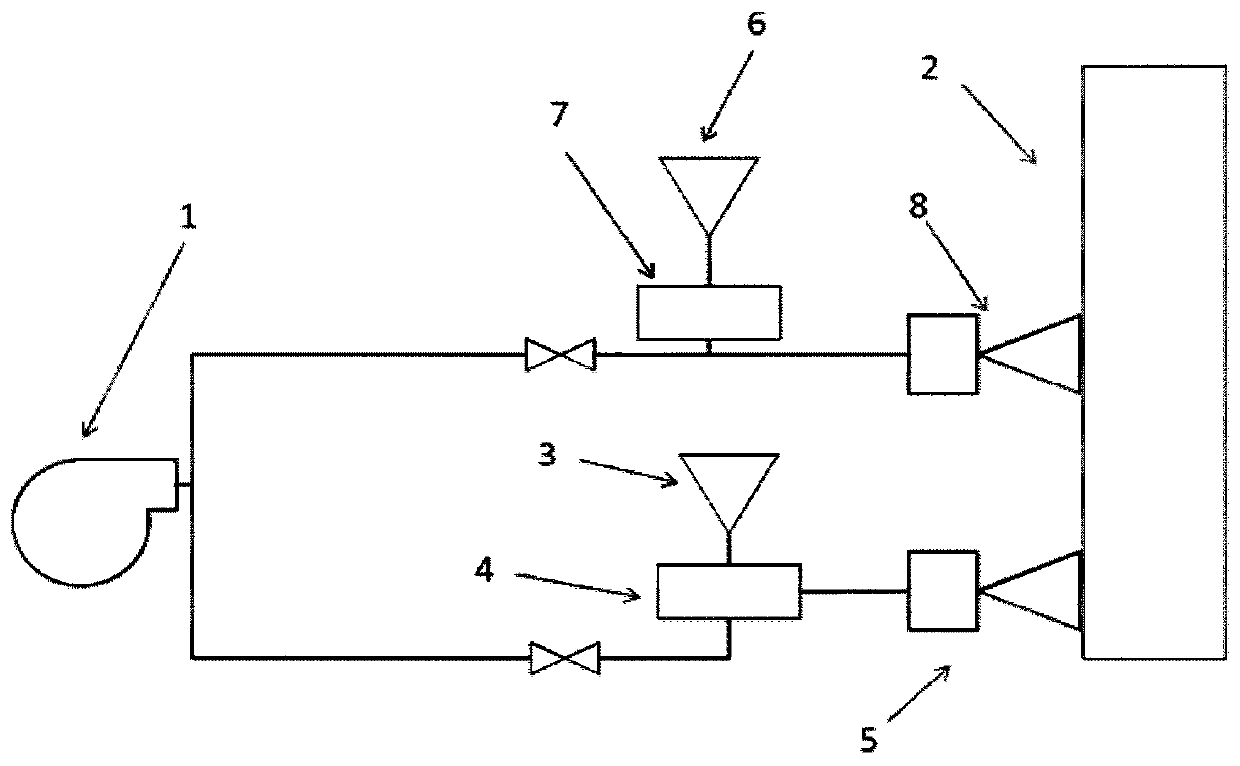

[0049] The decoking agent is sprayed into the coking hole or fire viewing hole of the boiler body of the existing coal-fired power plant, and it is equipped with a frequency conversion sleeve feeding system and a storage bin. The structure is as follows: figure 1 As shown, the decoking agent of this embodiment is put into the storage bin (6), and the mass of the decoking agent that needs to be added per un...

Embodiment 3

[0051] A coke slag conditioning type decoking agent suitable for high-sodium coal. The raw material components of the decoking agent and their weight percentages are as follows:

[0052] Magnesium chloride 70%, kaolin 13%, bentonite 10%, copper chloride 1%, potassium permanganate and manganese oxide 2%, nickel oxide 1%, dispersant 3%.

[0053] Add the decoking agent of this embodiment to the inlet of the powder feeder or the pulverized coal air duct through compressed air. The amount of the decoking agent added is 0.5‰ of the weight of the high-sodium coal. into the furnace for combustion.

[0054] The specific application method is as follows:

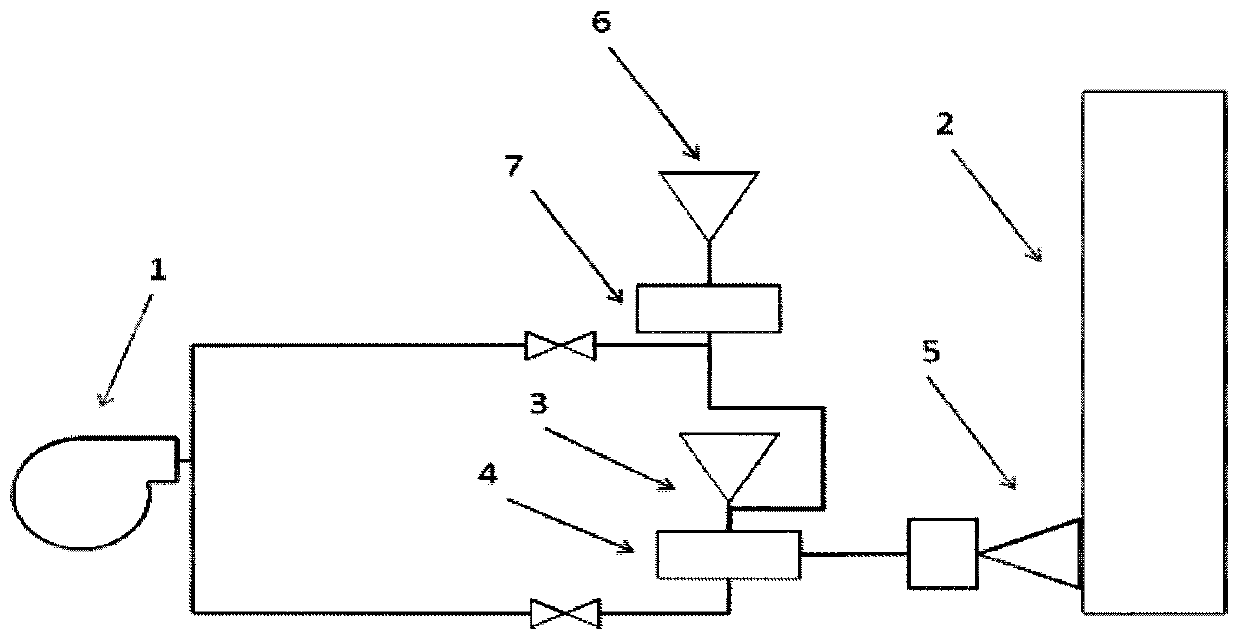

[0055] The feeding system used is equipped with a frequency conversion sleeve feeding system and a storage bin at the entrance of the pulverizer in the existing coal-fired power plant, and the decoking agent is dosed quantitatively. The structure is as follows figure 2 As shown, the decoking agent of this embodiment is put into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com