An additive for preventing high-alkali fuel from fouling and coking, its preparation method and application

A technology of additives and fuels, applied in fuel additives, fuels, liquid carbon-containing fuels, etc., can solve problems such as contamination, restrictions on the development of the coal power industry, boiler shutdown and coke cleaning accidents, etc., to achieve simple addition operations and flexible addition methods , Improve the effect of ash melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The embodiment of the present invention provides an additive for preventing high-alkali fuel from being stained and coked. The components of the additive and their corresponding mass percentages are shown in Table 1 below:

[0032] Table 1 Embodiment 1 Additive component mass percentage content table

[0033] ingredients

Titanium dioxide

water

mass percentage

15%

8%

2%

4%

5%

66%

[0034] Mix magnesium hydroxide, titanium dioxide, surfactant, and dispersant into water, and use mixing equipment to mix. The mixing temperature is 30°C, and the stirring speed is 800r / min to form slurry A; put the aluminum compound into the mixed slurry In A, the mixing equipment is used for stirring, the mixing temperature is 40°C, and the stirring speed is 400r / min to form the finished additive.

[0035] The finished additive is directly and evenly mixed w...

Embodiment 2

[0037] The embodiment of the present invention provides an additive for preventing high-alkali fuel from being stained and coked. The components of the additive and their corresponding mass percentages are shown in Table 2 below:

[0038] Table 2 Example 2 Additive component mass percentage content table

[0039] ingredients

magnesium hydroxide

Titanium dioxide

Hexametaphosphate

water

mass percentage

12%

5%

5%

3%

5%

70%

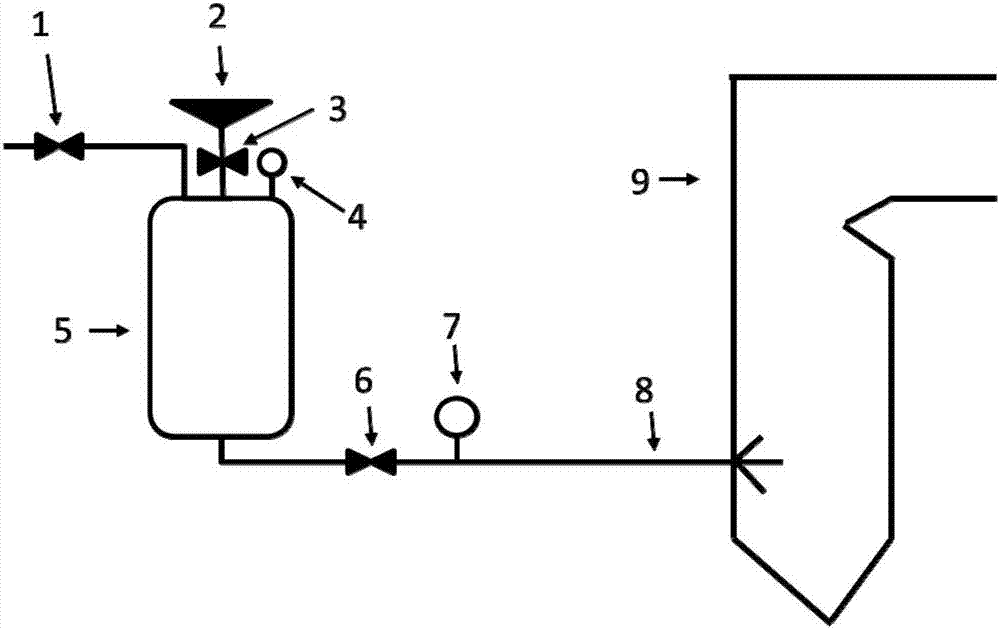

[0040] The additive in this embodiment is sprayed into the combustion area in the furnace through the fire viewing hole according to 3‰ of the coal burning amount by the spray gun, and Zhundong coal is selected as the coal burning. In this embodiment, the additive only needs to be sprayed into the coking hole or the fire viewing hole of the boiler body of the existing coal-fired power plant, and a storage tank and a spray gun are equipped. Compared with the Zh...

Embodiment 3

[0043] The embodiment of the present invention provides an additive for preventing high-alkali fuel from being stained and coked. The components of the additive and their corresponding mass percentages are shown in Table 3 below:

[0044] Table 3 embodiment 3 additive component mass percentage content table

[0045] ingredients

[0046] Its preparation method and addition method are the same as in Example 1, and its addition amount is 10‰ of the fuel mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com