Method for preparing nano-crystalline cellulose by taking corn stalks as raw materials and application thereof

A technology of nanocrystalline cellulose and corn stalks, which is applied in the fields of cellulose raw material pulping, cellulose pulp post-treatment, fiber raw material treatment, etc., can solve the problems of long preparation period, high cost, and comprehensive utilization of plant raw materials, etc. To achieve the effect of comprehensive utilization, environmental protection, low cost of raw materials, and strong comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

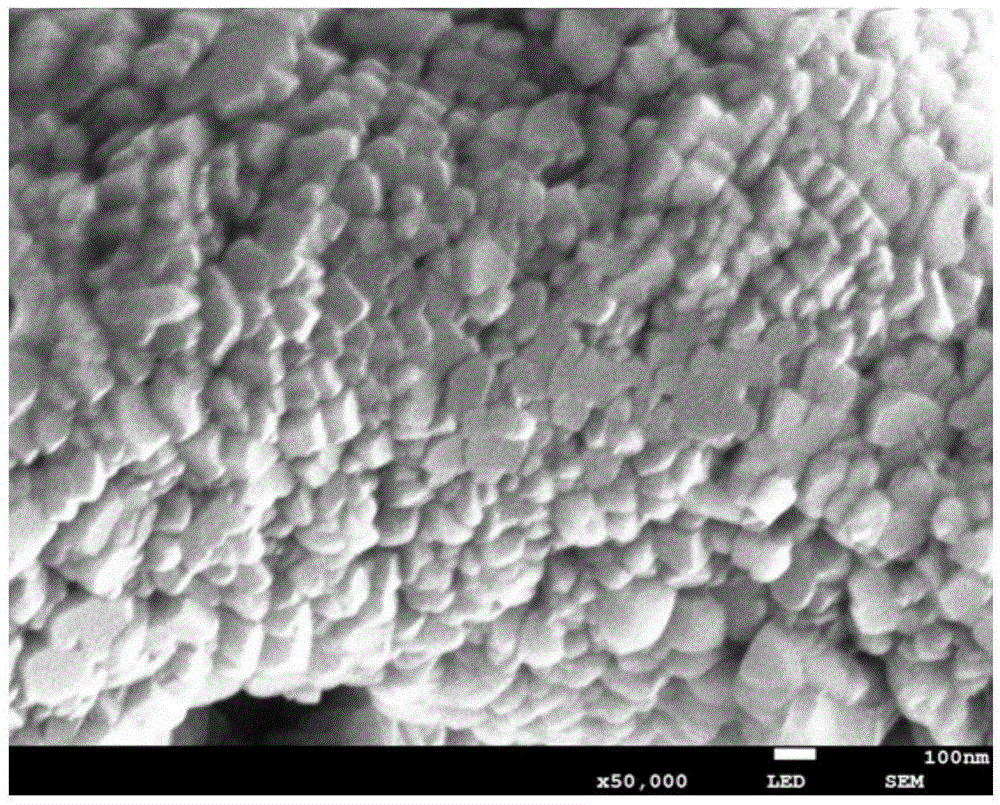

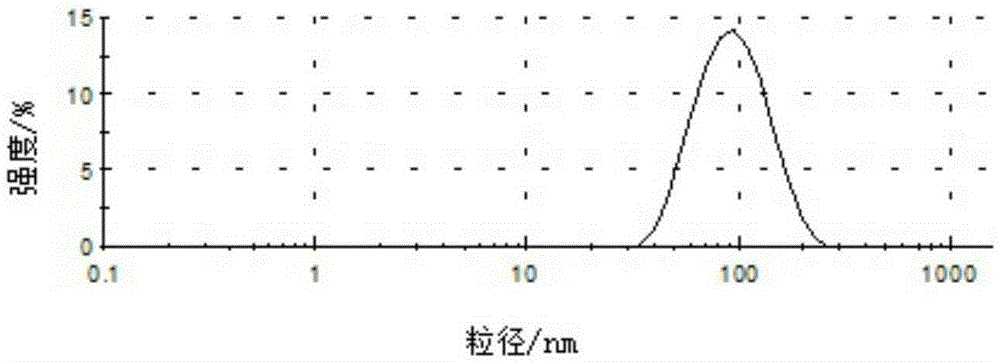

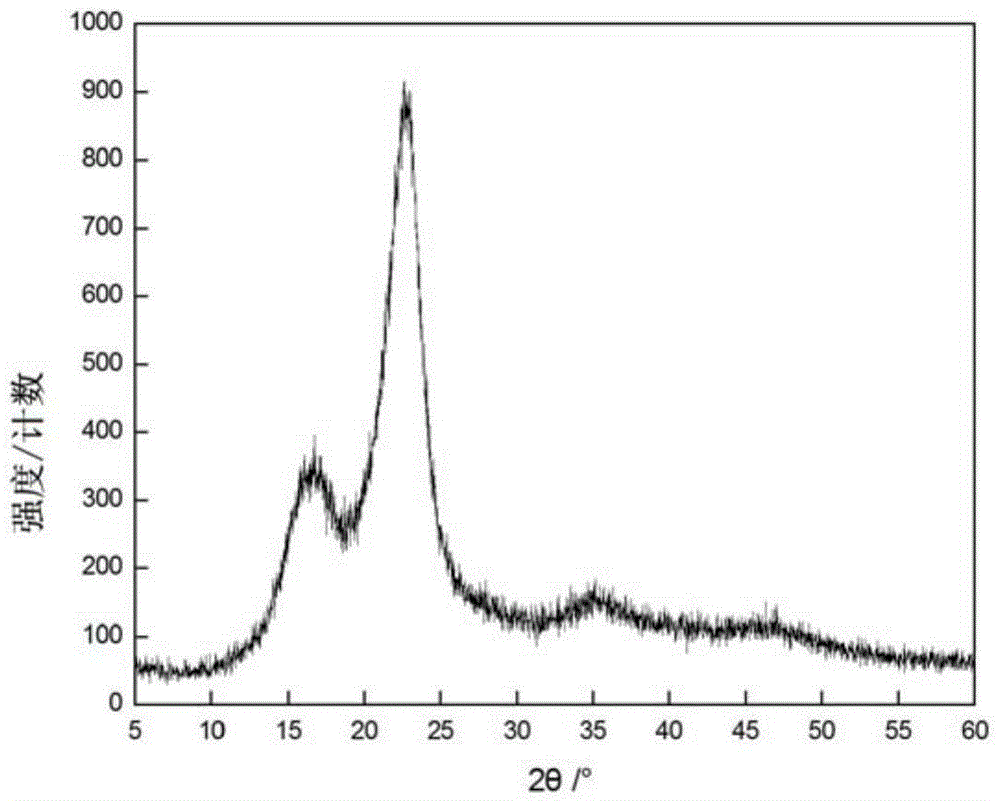

Image

Examples

Embodiment 1

[0043] (1) Pre-hydrolysis

[0044] Wash the corn stalks with water to remove impurities, cut them into 1-2cm long and 0.5cm wide sections after drying, and balance the moisture; then at 170°C, add water and glacial acetic acid, the amount of glacial acetic acid is 2% (glacial acetic acid and dry corn stalks The mass percent of skin), liquid ratio 5:1, process 30min, filter, wash with water;

[0045] (2) Kraft cooking

[0046] When the degree of sulfidation is 25%, the amount of alkali used is 16%, the liquid ratio is 5:1, steamed at 170°C for 60min, filtered, and washed with water;

[0047] (3) Bleaching

[0048] Add water and DTPA, pretreat for 30 minutes under the conditions of DTPA dosage 0.5%, slurry concentration 15%, temperature 40°C, pH 3, filter and wash with water;

[0049] Then at an oxygen pressure of 0.8MPa, add water, H 2 o 2 The dosage is 3%, the dosage of NaOH is 4%, the temperature is 80°C, MgSO 4 Dosage 0.4%, Na 2 SiO 3 The dosage is 3%, the pulp concent...

Embodiment 2

[0060] (1) Pre-hydrolysis

[0061] Wash the corn stalks with water to remove impurities, cut them into 1-2cm long and 0.5cm wide sections after drying, and balance the moisture; then at 170°C, add water and glacial acetic acid, the amount of glacial acetic acid is 2% (glacial acetic acid and dry corn stalks The mass percent of skin), liquid ratio 5:1, process 30min, filter, wash with water;

[0062] (2) Kraft cooking

[0063] When the degree of sulfidation is 25%, the amount of alkali used is 16%, the liquid ratio is 5:1, steamed at 170°C for 60min, filtered, and washed with water;

[0064] (3) Bleaching

[0065] Add water and DTPA, pretreat for 30 minutes under the conditions of DTPA dosage 0.5%, slurry concentration 15%, temperature 40°C, pH 3, filter and wash with water;

[0066] Then at an oxygen pressure of 0.8MPa, add water, H 2 o 2 The dosage is 3%, the dosage of NaOH is 4%, the temperature is 80°C, MgSO 4 Dosage 0.4%, Na 2 SiO 3 The dosage is 3%, the pulp conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com