Nutritional moringa oleifera salad sauce

A salad dressing and nutrition technology, applied in the field of Moringa nutritious salad dressing products, can solve the problems of not achieving weight loss effect, difficult to adhere to, and difficult to form an industry, and achieve a rich and lasting taste, reduce oil content, and reduce high calorie. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

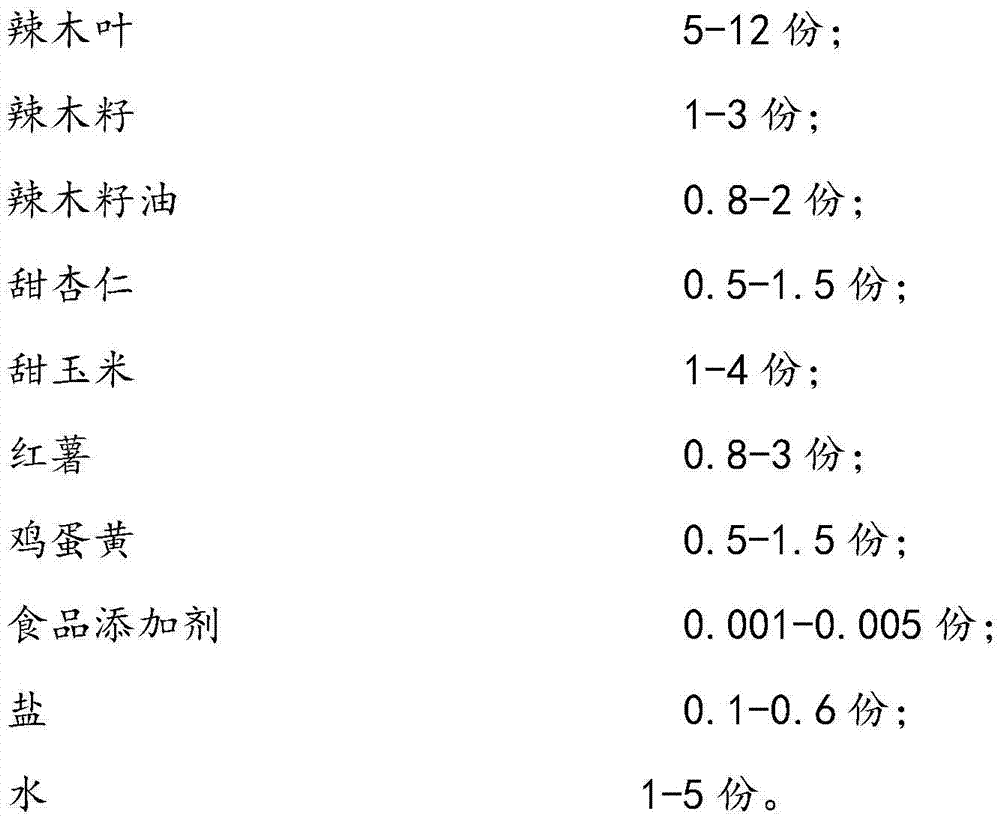

Method used

Image

Examples

preparation example Construction

[0051] The present invention also provides the preparation method of above-mentioned Moringa nutritious salad dressing, comprises the following steps:

[0052] S1 material preparation:

[0053] (1) After picking the fresh leaves of Moringa oleifera, rinse them with clean tap water, because Moringa oleifera is rarely infested by insects, no need to apply pesticides, and it is non-toxic, just rinse it a little. Then the fresh Moringa leaves are sterilized on a conveyer belt at a temperature of 280-300° C., dried to about 90% dry, retaining about 3%--5% of moisture, and then the dried Moringa leaves are re- After transporting to another conveyor belt to cool naturally for 15 minutes, put it into a food packaging bag and pack it for use. The conveyor belt speed is about 30-60r / min.

[0054] (2) Cut the Moringa seeds with a granulator, cut about 2--3 petals per grain, soak them in cold water for 10-15 hours in advance, change the water 2-4 times during the process, and remove the...

Embodiment 1

[0067] Wash and dry the fresh leaves of Moringa oleifera, retaining about 3%--5% of water;

[0068] Cut the Moringa seeds, cut one into about 2--3 petals, soak in cold water for 10 hours, and drain after soaking;

[0069] Cooked and peeled sweet potatoes;

[0070] sweet corn husk;

[0071] Sweet almonds are roasted with slow fire to produce fragrance;

[0072] Take 6 parts of dried Moringa leaves, 1 part of Moringa seeds, 0.5 parts of sweet almonds, 1 part of Moringa seed oil, 2 parts of sweet corn kernels, 1.5 parts of sweet potatoes, 0.6 parts of egg yolk, 0.2 parts of salt, 2 parts of water, and remove 0.001 parts of sodium hydroacetate.

[0073] Use a wall-breaking machine (45,000 rpm) to grind the dried leaves of Moringa into fine powder with a particle size of 200, pour it out and prepare it for later use; then put soaked Moringa seeds, sautéed sweet almonds, sweet corn, Mix the cooked sweet potatoes with water and put them into a wall breaker to make a slurry for ab...

Embodiment 2

[0075] Wash and dry the fresh leaves of Moringa oleifera, retaining about 3%--5% of water;

[0076] Cut the Moringa seeds, cut one into about 2--3 petals, soak in cold water for 15 hours, and drain after soaking;

[0077] Cooked and peeled sweet potatoes;

[0078] sweet corn husk;

[0079] Sweet almonds are roasted with slow fire to produce fragrance;

[0080] Take 12 parts of dried Moringa leaves, 3 parts of Moringa seeds, 1.5 parts of sweet almonds, 2 parts of Moringa seed oil, 4 parts of sweet corn kernels, 3 parts of sweet potatoes, 3 parts of flour, 1.5 parts of egg yolk, 0.6 parts of salt, bread 0.09 parts of baking powder, 5 parts of water, 0.003 parts of sodium dehydroacetate.

[0081] Use a wall-breaking machine (45,000 rpm) to grind the dried leaves of Moringa into fine powder with a particle size of 200, pour it out and prepare it for later use; then put soaked Moringa seeds, sautéed sweet almonds, sweet corn, Mix the cooked sweet potatoes with water and put the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com