Carbazochrome sodium sulfonate freeze-dried powder injection and preparation method thereof

The technology of freeze-dried powder injection and sodium carboxysulfonate, which is applied in the field of pharmaceutical preparations, can solve the problems of increased impurity content and poor quality stability of sodium carboxylate powder for injection, achieves good appearance, stable content, and is beneficial to industrialization. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

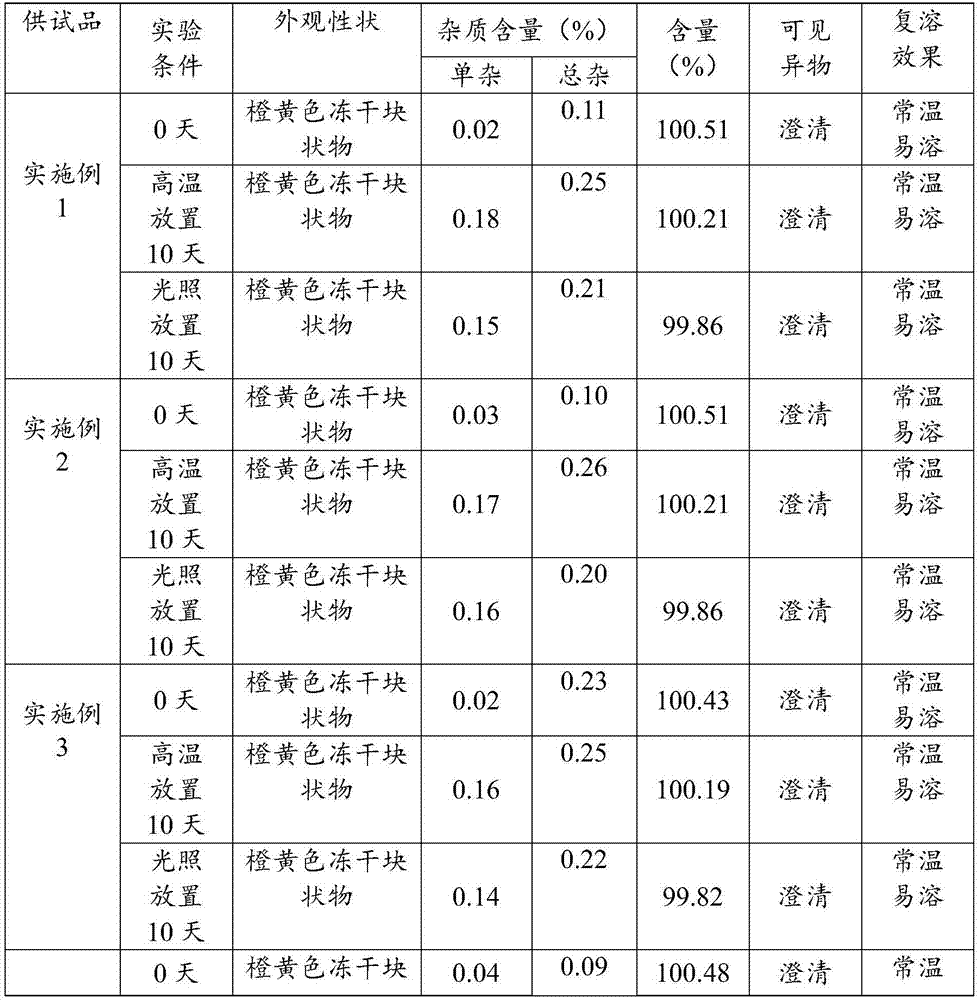

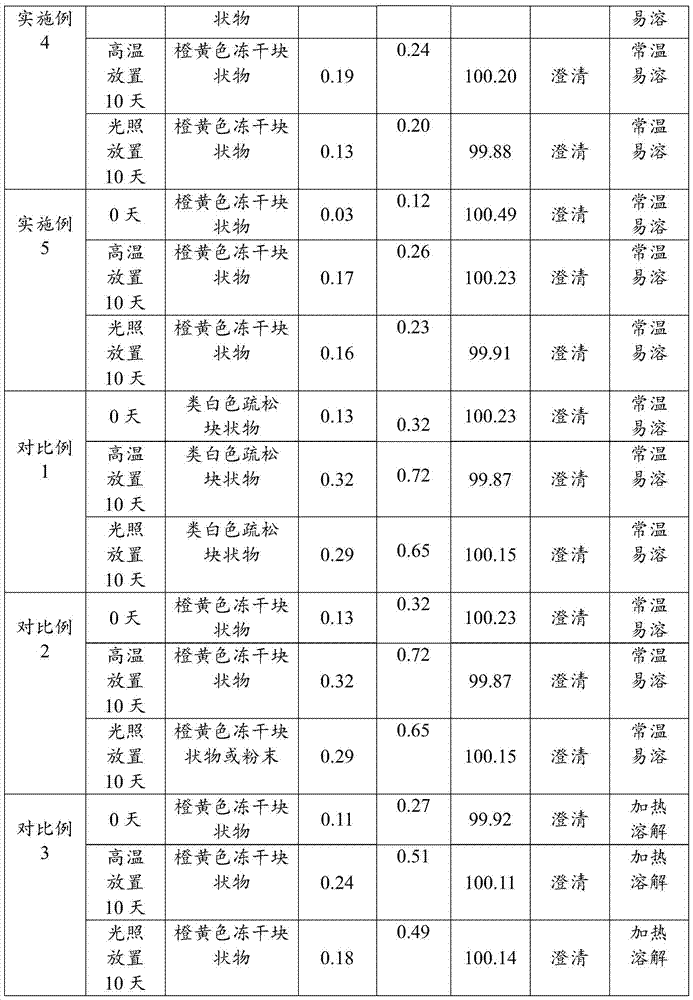

Examples

Embodiment 1

[0078] The freeze-dried powder injection of sodium carbosulfonate in this embodiment consists of the following raw materials:

[0079] Sodium carbosulfonate 20g, water for injection 2000mL;

[0080] Its preparation method comprises the following steps:

[0081] (1) Take 80% of the selected volume of water for injection, add the selected weight of sodium carbosulfonate, stir until completely dissolved, adjust and control the water temperature to 75°C to obtain solution A;

[0082] (2) Take 20% of the selected volume of water for injection, add it to the solution A, stir until it is completely dissolved, adjust and control the pH value to 5.0-6.0, and pre-filter it through a plate and frame filter to obtain solution B;

[0083] (3) The solution B is sterilized and filtered with two 0.22 μm polyethersulfone filter elements to obtain the solution C, which is filled and half-tamped to obtain the intermediate product D;

[0084] (4) The intermediate product D is subjected to freez...

Embodiment 2

[0094] The freeze-dried powder injection of sodium carbosulfonate in this embodiment consists of the following raw materials:

[0095] Sodium carbosulfonate 40g, water for injection 2000mL;

[0096] Its preparation method comprises the following steps:

[0097] (1) Take 75% of the selected volume of water for injection, add the selected weight of sodium carbosulfonate, stir until completely dissolved, adjust and control the water temperature to 70°C to obtain solution A;

[0098] (2) Take 25% of selected volume of water for injection, add it to the solution A, stir until it is completely dissolved, adjust and control the pH value to 4.5-5.5, and pre-filter through a plate and frame filter to obtain solution B;

[0099] (3) The solution B is sterilized and filtered with two 0.22 μm polyethersulfone filter elements to obtain the solution C, which is filled and half-tamped to obtain the intermediate product D;

[0100] (4) The intermediate product D is subjected to freeze-dryin...

Embodiment 3

[0110] The freeze-dried powder injection of sodium carbosulfonate in this embodiment consists of the following raw materials:

[0111] Sodium carbosulfonate 30g, water for injection 2000mL;

[0112] Its preparation method comprises the following steps:

[0113] (1) Take 85% of the selected volume of water for injection, add the selected weight of sodium carbosulfonate, stir until completely dissolved, adjust and control the water temperature to 80°C to obtain solution A;

[0114] (2) Take 15% selected volume of water for injection, add it to the solution A, stir until completely dissolved, adjust and control the pH value to 5.5-6.5, and pre-filter through a plate and frame filter to obtain solution B;

[0115] (3) The solution B is sterilized and filtered with two 0.22 μm polyethersulfone filter elements to obtain the solution C, which is filled and half-tamped to obtain the intermediate product D;

[0116] (4) The intermediate product D is subjected to freeze-drying treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com