Numerically-controlled planar drill for processing round and square plates

A square plate and plane drilling technology, which is applied to metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problem that circular plates cannot be processed, and achieves diverse clamping forms, simple structure, and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific drawings.

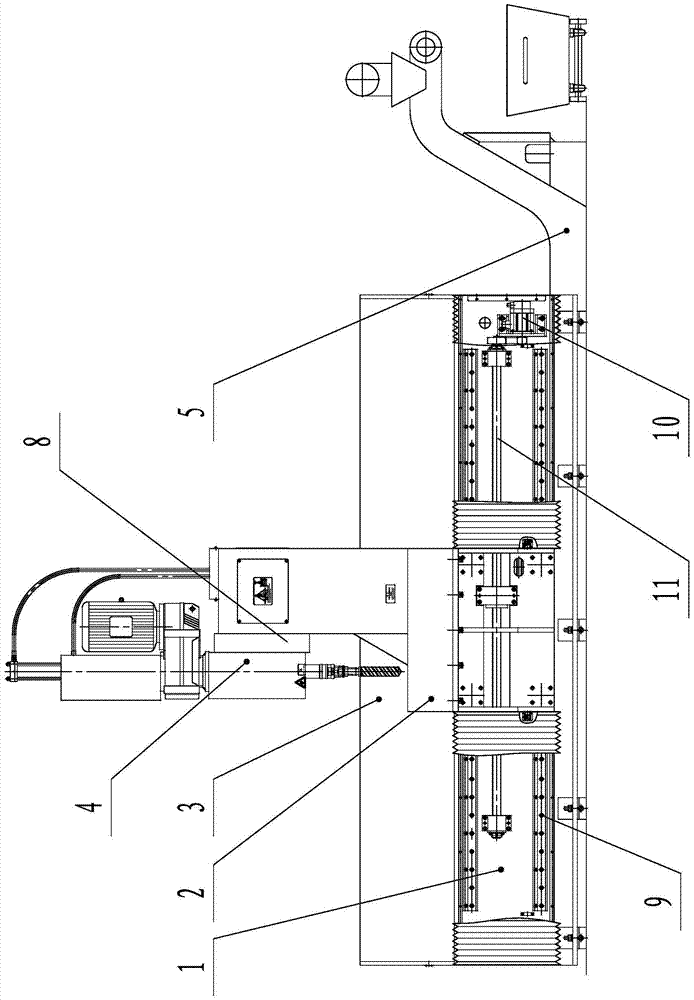

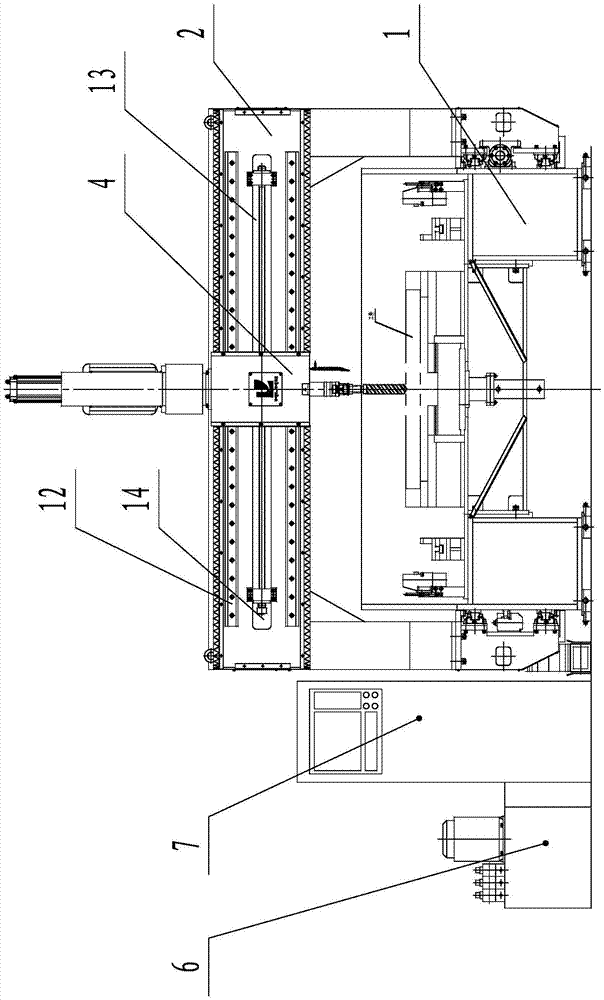

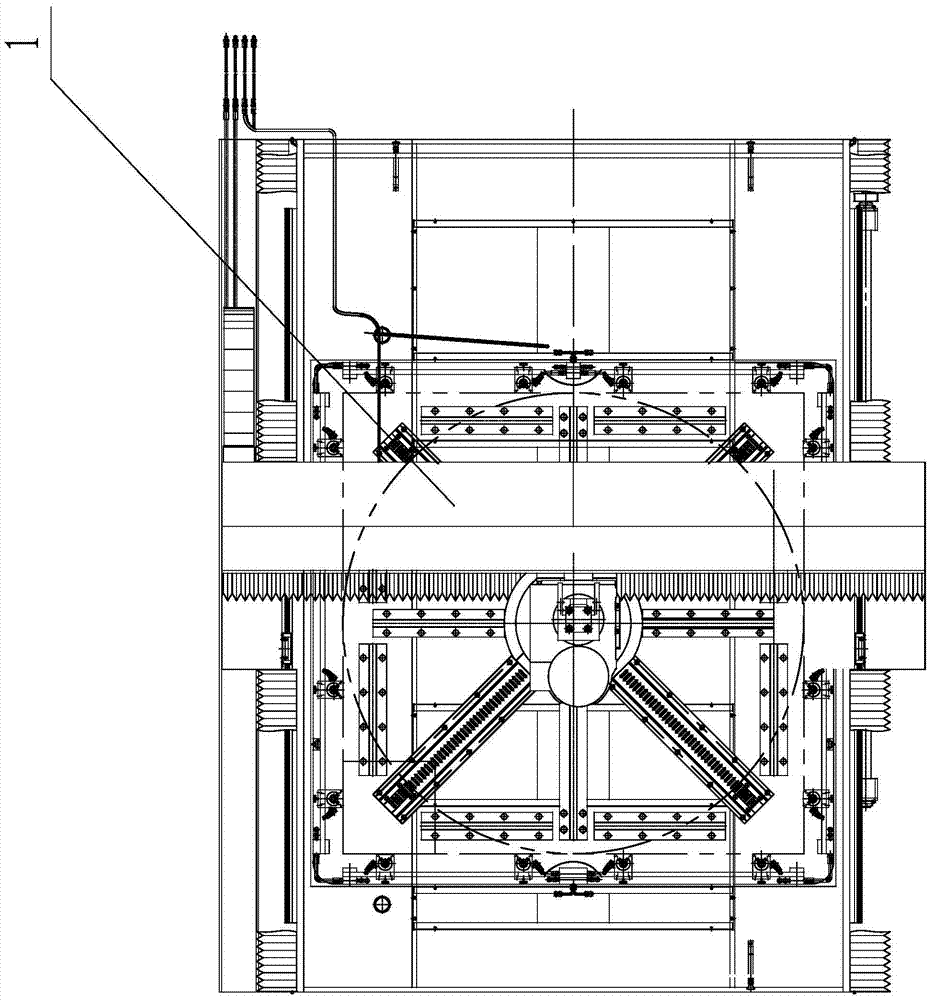

[0021] Such as Figure 1 ~ Figure 3 As shown: the CNC plane drill for processing round and square sheets includes a bed assembly 1, a mast assembly 2, a workbench assembly 3, a drilling head assembly 4, a chip removal system 5, a hydraulic system 6, and a numerical control electrical system 7. Mobile sliding table 8, first linear guide pair 9, first servo motor 10, first ball screw pair 11, second linear guide pair 12, second ball screw pair 13, second servo motor 14, etc. .

[0022] Such as Figure 1 ~ Figure 3 As shown, the CNC plane drill for processing circular and square sheets according to the present invention includes a bed assembly 1, the bed assembly 1 is installed on the ground through embedded bolts and adjusting shims, and the adjustment and adjustment shims make the bed assembly 1 left and right In the same plane; a workbench assembly 3 is installed on the bed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com