Method of utilizing microwave energy to prepare calcium carbide at low temperature

A technology of microwave energy and calcium carbide, applied in the direction of carbide, calcium carbide, etc., can solve the problems of high energy consumption, high investment, high pollution, etc., and achieve the effects of short process, low cost and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

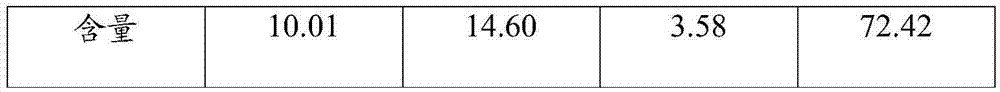

[0025] Fujian anthracite (see Table 1 for the composition of anthracite) and limestone (mass content of calcium carbonate greater than 98%) with a particle size of 0.5-5mm after initial grinding were mixed according to the molar ratio of C:Ca=4:1 and then ultra-finely ground to obtain The superfine mixed material whose particle size is less than 40μm accounts for more than 90%. Press it into a disc with a diameter of 5 cm and a thickness of 1 cm under a hydraulic press with a pressure of 50 MPa. Each piece weighs about 20g. The above 3 pieces of mixed raw materials were placed in the crucible of the microwave reactor, and the microwave power was adjusted so that the reaction temperature rose from room temperature to 1700°C within 45mins and kept at 1700°C for 30min. After the reaction was completed, the temperature was lowered to 400° C., and the material was taken out. The surface of the material is gray-black, and the whole shrinks and agglomerates, which is the obtained c...

Embodiment 2

[0030] The molar ratio of C:Ca=4:1 in Example 1 was used for direct reaction. Weigh 60.0 g of the above powder and place it in the crucible of a microwave reactor, adjust the microwave power to increase the reaction temperature from room temperature to 1700 °C within 45 mins and keep it at 1700 °C for 30 min. After the reaction was completed, the temperature was lowered to 400° C., and the material was taken out. The surface of the material is off-white, the interior is gray-black, crisp and loose without sintering, which is the obtained calcium carbide product. The product was detected by gas evolution, and its gas evolution capacity reached 277L / Kg.

Embodiment 3

[0032] The molar ratio of C:Ca=4:1 in Example 1 was used for direct reaction. Weigh 60.0 g of the above powder and place it in the crucible of a microwave reactor, adjust the microwave power to increase the reaction temperature from room temperature to 1400 °C within 30 mins and keep it at 1400 °C for 20 min. After the reaction was completed, the temperature was lowered to 400° C., and the material was taken out. The surface of the material is gray-black, the inside is black, crisp and loose without sintering, which is the obtained calcium carbide product. The product was detected by gas evolution, and its gas evolution capacity reached 129L / Kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Gas output | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com