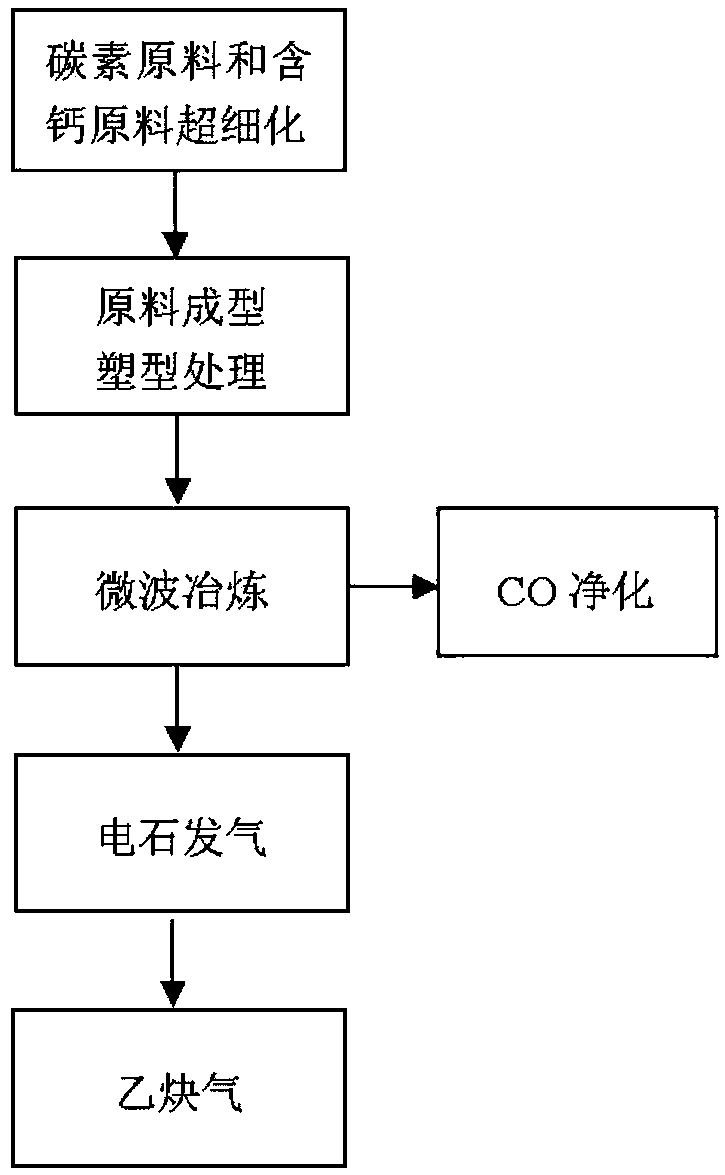

Method and system used for preparing acetylene from coal-based calcium carbide

A technology of calcium carbide and acetylene, applied in the field of coal chemical industry, can solve problems such as pollution, environmental pollution, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

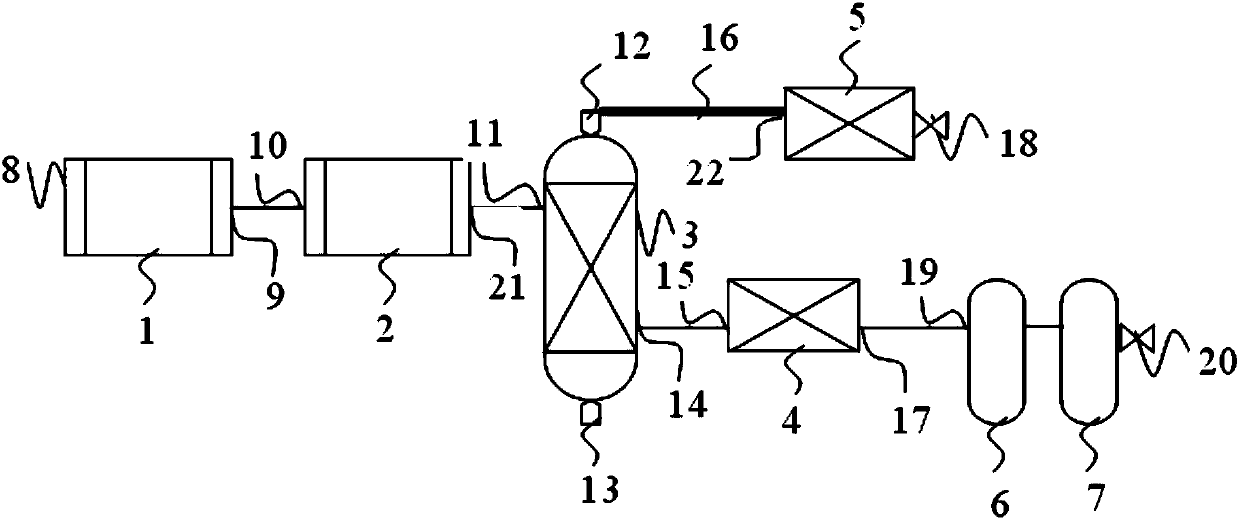

Embodiment 1

[0048] see figure 2 . Metallurgical coke and quicklime are mixed according to the carbon-calcium molar ratio of 2.8:1, and then passed through a pulverizer (1) and ground into a mixed ultrafine powder with a particle size distribution between 30-80nm. The industrial analysis of metallurgical coke is shown in Table 1. The fixed carbon content is 84.73%, and the calcium oxide content in quicklime is greater than 99%. The mixed superfine powder is fed into the tablet press (2) through the feeding port (10), and the pressure is 6 MPa to press the tablet to obtain a cylindrical block material with a diameter of 40 mm and a height of 10-15 mm. The material is placed in the self-developed microwave smelting calcium carbide furnace (3) through the material inlet (11), and argon gas is passed into the microwave smelting calcium carbide furnace (3) through the gas inlet (13) to perform atmosphere replacement. Then microwave heating in an argon atmosphere to raise the temperature to 1...

Embodiment 2

[0052] The metallurgical coke and the calcite are respectively pulverized into superfine metallurgical coke powder and calcite superfine powder with a particle size of 80-120nm through secondary crushing. The industrial analysis of metallurgical coke is shown in Table 1, and the content of calcium carbonate in calcite is greater than 97%. The above-mentioned superfine powder of metallurgical coke and calcite is mixed according to the ratio of carbon to calcium molar ratio of 4.5:1, and the mass fraction rate is 3% diesel oil, and then sent to the double-roll tablet machine, and the pressure is 6.5MPa. Form a cylindrical granular material with a diameter of 5mm and a height of 10mm. The material was placed in a self-developed microwave smelting calcium carbide furnace, and the atmosphere was first replaced with argon. Then microwave heating in an argon atmosphere to 1680°C and maintain for 1h. The tail gas generated during the reaction enters the exhaust pipe and passes throug...

Embodiment 3

[0054] The anthracite and quicklime are pulverized into anthracite superfine powder and quicklime superfine powder with a particle size of 100-150nm through secondary crushing. The industrial analysis of anthracite is shown in Table 2, and the content of calcium oxide in quicklime is greater than 99%. The above-mentioned ultrafine powder of anthracite and quicklime is uniformly mixed according to the ratio of carbon to calcium molar ratio of 3:1, and then sent into a tablet press, and a spherical material with a diameter of 5mm is prepared under a pressure of 6.5MPa. The materials were placed in a self-developed microwave smelting calcium carbide furnace, and the atmosphere was first replaced with argon. Then microwave heating in an argon atmosphere to 1800°C and maintain a constant temperature for 1 hour. The tail gas generated during the reaction enters the exhaust pipe and passes through the separation device to obtain a gas product with high CO content. The CO content is 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com