Preparation method of high-purity molten iron

A molten iron, high-purity technology, applied in the field of preparation of high-purity molten iron, can solve the problems of long smelting process and high energy consumption, and achieve the effect of improving smelting efficiency, high energy consumption and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

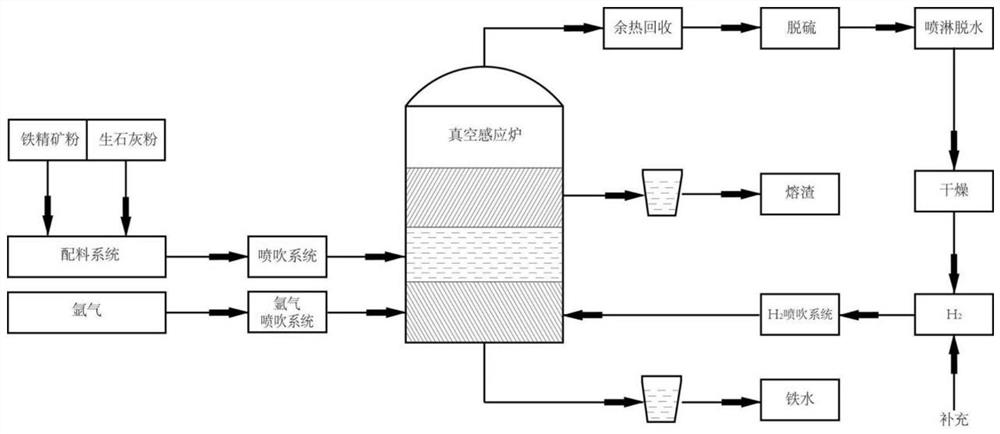

[0032] The present invention also provides a method for preparing high-purity molten iron, the method comprising the following steps:

[0033] Step 1. Add industrial pure iron into the vacuum induction furnace as the induction heating medium, heat and melt under vacuum at 50-100 Pa, and set the melting temperature to 1550-1700 ° C; then add iron concentrate powder and lime flux;

[0034] Step 1. At the beginning, put industrial pure iron as the induction heating medium into the vacuum induction furnace, heat and melt under the condition of 50-100Pa and 1550-1700°C in a vacuum state, and form a molten iron pool after melting;

[0035] Step 2. Continuously spray the iron concentrate powder and lime flux into the molten iron pool in step 1 for melting pre-reduction, and form a melt after melting and pre-reduction; The hydrogen injection unit at the bottom of the furnace sprays hydrogen into the molten iron pool, and the hydrogen reacts with the melt in the molten iron pool for sm...

Embodiment 1

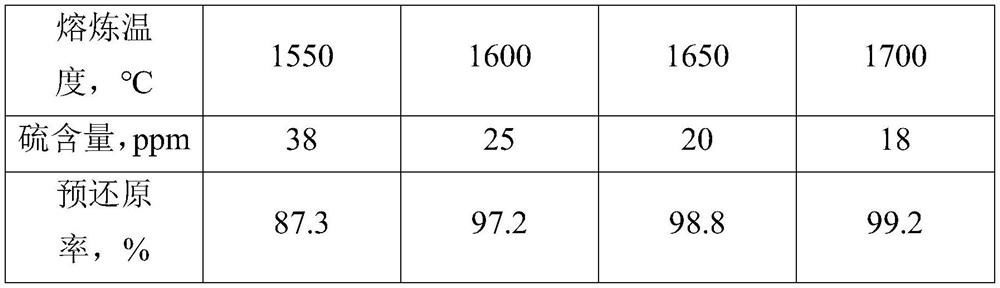

[0072] This example is used to illustrate the influence of smelting temperature on oxidative desulfurization and pre-reduction. Among them, the composition of the selected iron concentrate powder is shown in Table 1, the total iron content is 67%, and the sulfur and phosphorus contents are both 0.01%. Using CaO pure chemical reagent as flux, iron concentrate powder and calcium oxide are mixed according to the ratio of binary alkalinity to 3.0.

[0073] Table 1 Iron Concentrate Powder Composition

[0074] Element TF FeO Fe 2 o 3

al 2 o 3

CaO MgO SiO 2

P S content,% 67 1.04 94.6 0.64 0.89 0.68 2.61 0.03 0.01

[0075] Add 10kg of industrial pure iron into a vacuum induction furnace with a capacity of 50kg as an induction heating medium, and heat and melt it in a vacuum state to form a molten iron pool. The melting temperature is set to 1550-1700°C. After the pure iron is completely melted, spray 10kg of the mixture of ...

Embodiment 2

[0085] This example is used to illustrate the effect of slag basicity on the sulfur and oxygen content of molten iron, wherein iron concentrate powder and calcium oxide flux are mixed according to the ratio of binary basicity 2.0, 2.5, 3.0, 3.5. After the pre-reduction is carried out according to the same procedure as above, pure hydrogen is injected into the molten pool through a hydrogen spray gun for final reduction, and the amount of hydrogen injected is according to H 2 The / FeO molar ratio is controlled at 2, the injection time is 30min, and the melting temperature is 1650°C. After reaching the reduction reaction time, the sulfur content and oxygen content of the molten iron were measured by a carbon-sulfur analyzer and chemical analysis, and the results are shown in Table 3.

[0086] It can be seen that the increase of slag alkalinity has a favorable impact on both desulfurization and deoxidation of molten iron. When the alkalinity is controlled above 2.5, the sulfur an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com