PCB (printed circuit board) ink wastewater treatment method and system thereof

A technology of ink waste water and treatment system, applied in water/sewage treatment, water treatment parameter control, neutralization water/sewage treatment, etc., can solve the problems of high labor intensity, difficult process control, cumbersome cleaning process of treatment process, etc. The effect of reducing labor intensity and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

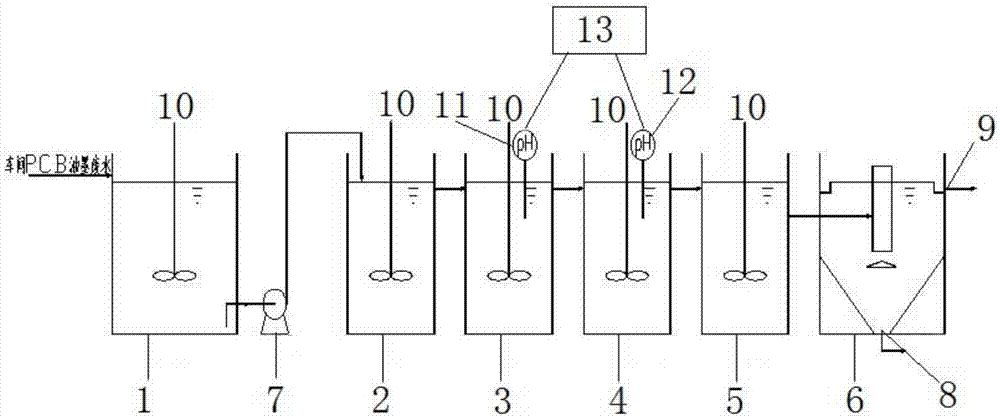

[0021] Such as figure 1 As shown, a PCB ink wastewater treatment system includes a regulating tank 1 , a polymerization reaction tank 2 , an acidification reaction tank 3 , a neutralization reaction tank 4 , a flocculation reaction tank 5 and a sedimentation tank 6 .

[0022] Among them, the regulating pool 1 receives the ink waste water flowing out from the PCB workshop, and is used to regulate the water quality and quantity. In order to prevent the precipitation of pollutants in the waste water, a stirring and mixing device 10 is also provided inside it.

[0023] A lift pump 7 is provided between the adjustment tank 1 and the polymerization reaction tank 2 , and the lift pump 7 is used to transport the sewage to the polymerization reaction tank 2 .

[0024] The polymerization reaction tank 2 is used to suppress the precipitation of scum after acid addition, and its upper part is provided with a feeding port for adding polyferric sulfate, and a stirring and mixing device 10 ...

Embodiment 2

[0030] A method for treating PCB ink waste water, using the PCB ink waste water treatment system described in embodiment 1, which comprises the steps:

[0031] First, adjust the water quality and quantity of the wastewater flowing from the PCB workshop through the regulating pool;

[0032] Next, add polyferric sulfate to the PCB ink wastewater in the polymerization tank, the amount of which is 500-1000 mg / L, and stir and react rapidly for 5 minutes.

[0033] Next, sulfuric acid was added into the acidification reaction tank to control the pH at 3-3.5, and the reaction was fully stirred and mixed for 10 minutes.

[0034] Then, sodium hydroxide was added into the neutralization reaction tank to control the pH at 6.5-9.0, and the mixture was fully stirred and reacted for 5 minutes.

[0035] Next, add polyacrylamide into the flocculation reaction tank, the input amount is 5-10 mg / L, and fully stir and mix for 15 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com