Functional highly-syndiotactic polystyrene and preparation method thereof

A polystyrene and polystyrene technology, applied in the field of polymers, can solve the problems of polystyrene polarity characterization and achieve high syndiotactic selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The preparation method of functionalized high syndiotactic polystyrene provided by the present invention includes:

[0060] Under the action of the catalyst, the functionalized styrene is polymerized to obtain functionalized high syndiotactic polystyrene;

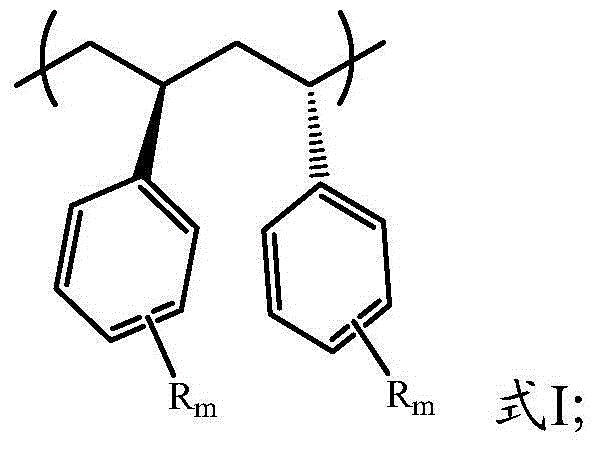

[0061] The functionalized styrene has the structure shown in formula II:

[0062]

[0063] In formula II, T is an alkoxy group having 1 to 20 carbon atoms, an aryloxy group having 6 to 20 carbon atoms, an alkylthio group having 1 to 20 carbon atoms, and a C6-20 group Arylthio or aryl with 6-20 carbon atoms; T is substituted at any position on the benzene ring;

[0064] n represents the number of substituents T, 1≤n≤5;

[0065] The catalyst includes rare earth complexes, organoboron compounds and organoaluminum compounds.

[0066] The present invention uses the coordination polymerization method to prepare and synthesize functionalized high syndiotactic polystyrene with sulfur and oxygen element functional groups. The functiona...

Embodiment 1

[0122] At 25°C, 10μmol of rare earth complex with the structure shown in formula 1, 10μmol[Ph 3 C][B(C 6 F 5 ) 4 ], 100μmol of triisobutylaluminum and toluene were mixed for 2 minutes, and the molar concentration of the rare earth complex was 2.0mmol·L -1 Catalyst solution.

Embodiment 2~ Embodiment 41

[0124] According to the method described in Example 1, the conditions in Table 1 were used to prepare the catalyst solutions; Table 1 shows the conditions for preparing the catalyst solutions in Examples 2 to 41. In the present invention, the amount of rare earth complexes in Example 2 to Example 41 are all 10 μmol.

[0125] Table 1 Conditions for preparing catalyst solutions in Example 2 to Example 41

[0126]

[0127]

[0128]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com