Epoxy resin enhanced rubber material as well as preparation method and application thereof

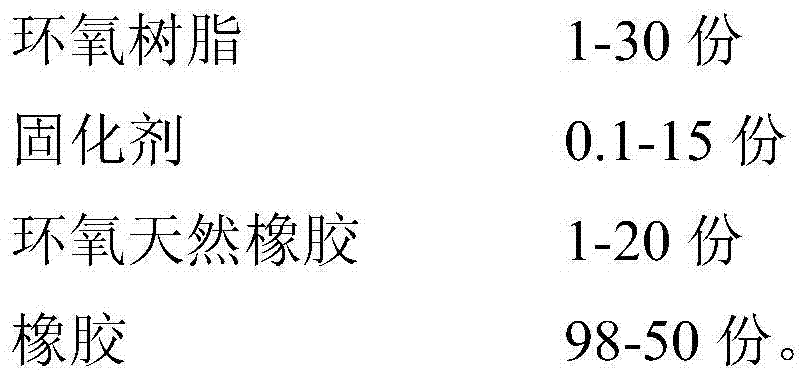

A technology of epoxy resin and rubber materials, applied in the field of composite materials, can solve the problems of poor compatibility and insignificant enhancement effect, and achieve the effect of low equipment requirements, enhanced two-phase compatibility, and easy industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In parts by weight, weigh 5 parts of bisphenol A epoxy resin E44 (epoxy value 0.44mol / 100g), add 1 part of curing agent 4,4'-diaminodiphenylmethane (DDM), and mix well at room temperature Uniformly (the time of mixing is to mix 3min), obtain mixture; 90 parts of styrene-butadiene rubbers and 5 parts of epoxy natural rubbers are masticated evenly on the open mill (the masticating temperature is 40 ℃, masticating time is 3min), covered with rolls, add all the mixture of E44 and DDM, knead evenly (mixing temperature is 45°C, kneading time is 6min), add active agent (4 parts of zinc oxide and 2 parts of stearic acid) in sequence , an accelerator (1.5 parts of CZ and 0.5 parts of DM), 2 parts of sulfur, and continue mixing for 6 minutes to obtain a mixed rubber; the obtained mixed rubber was vulcanized at 150° C. for 10 minutes to obtain an epoxy resin-reinforced rubber material.

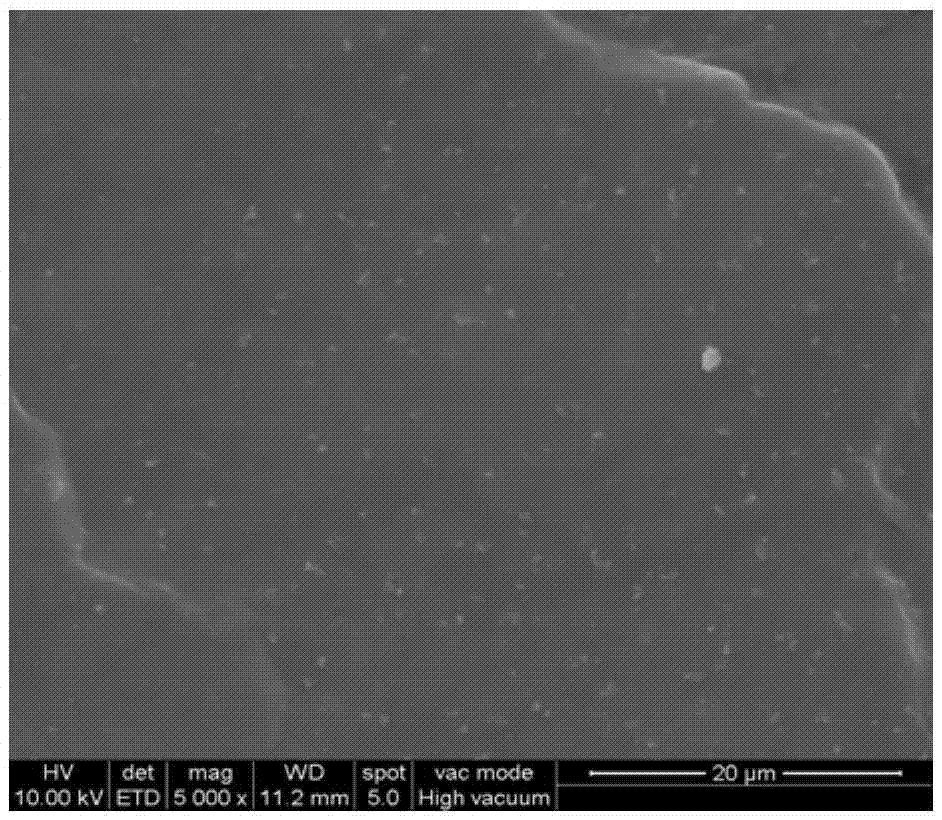

[0047] The rubber material reinforced by epoxy resin was brittle in liquid nitrogen, and the e...

Embodiment 2

[0049] In parts by weight, weigh 10 parts of bisphenol A epoxy resin E51 (epoxy value 0.51mol / 100g), add 2 parts of curing agent 4,4'-diaminodiphenylsulfone (DDS), and mix well at room temperature Uniformly (the time of mixing is 3min), obtains mixture; 82 parts of natural rubbers and 8 parts of epoxy natural rubbers of epoxy degree 30% are masticated evenly on the open mill (the masticating temperature is 45 ℃, and the masticating time is 4min) , wrapping rolls, adding all the mixture of E51 and DDS, kneading evenly (mixing temperature is 45 ° C, kneading time is 6min), sequentially add active agent (4 parts of zinc oxide and 2 parts of stearic acid), accelerator ( 1.5 parts of CZ and 0.5 parts of DM), 2 parts of sulfur, and continued mixing for 8 minutes to obtain a mixed rubber; the obtained mixed rubber was vulcanized at 143° C. for 12 minutes to obtain an epoxy resin-reinforced rubber material.

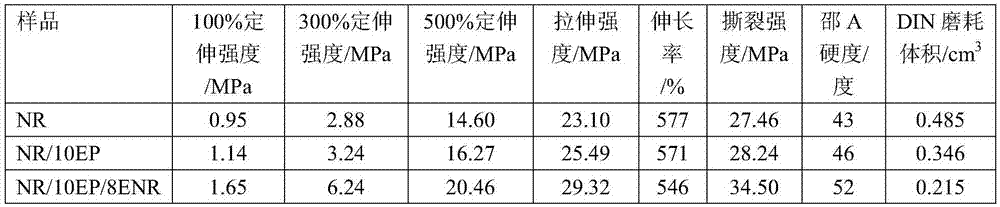

[0050] Natural rubber and E44 composite material (NR / 10EP), natural rubber (...

Embodiment 3

[0054] Weigh 5 parts of novolac epoxy resin F51 (epoxy value 0.51mol / 100g) by weight, add 2 parts of curing agent 2-ethylimidazole (2-MI), and mix well at room temperature (the mixing time is 3min), to obtain the mixture; 92 parts of styrene-butadiene rubber and 3 parts of natural rubber of epoxy degree 50% epoxy are masticated evenly on the open mill (the masticating temperature is 45 ℃, and the masticating time is 3min), wrapped with rolls, Add all the mixture of F51 and 2-MI, knead evenly (mixing temperature is 40°C, kneading time is 8min), add active agent (zinc oxide 4 parts and stearic acid 2 parts), accelerator (CZ1. 5 parts and 0.5 parts of DM), 2 parts of sulfur, and continued to knead for 8 minutes to obtain a mixed rubber; the obtained mixed rubber was vulcanized at 150° C. for 9 minutes to obtain an epoxy resin-reinforced rubber material.

[0055] The epoxy resin-reinforced rubber material in this example and the SBR / EP rubber without adding epoxy natural rubber we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com