Polymer thickener for high-temperature-resistant water-based fracturing fluid and production method for polymer thickener

A technology for water-based fracturing, polymers, compositions for drilling, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The weight percent of each monomer and water: AM:AA:PSNN:APEG:DMDAAC:MBA=450:250:80:0.4:18:0.02.

[0026] Solution preparation: Add 201.58g of distilled water into a 2000ml beaker, add 450g of AM monomer, 250g of AA monomer, add 80g of PSNN monomer, add 0.4g of APEG monomer, add 18g of DMDAAC monomer, add 0.02g of MBA monomer, Stir to dissolve for 30 minutes, and slowly add 40% NaOH solution under stirring condition to adjust the pH to 6-7. Continue to stir the solution for 20 min under the condition of feeding nitrogen gas at a certain flow rate to remove dissolved oxygen in water.

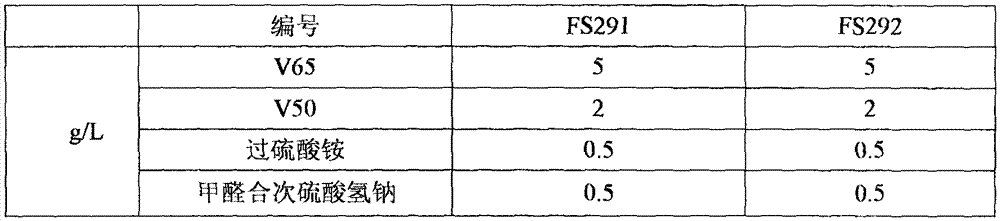

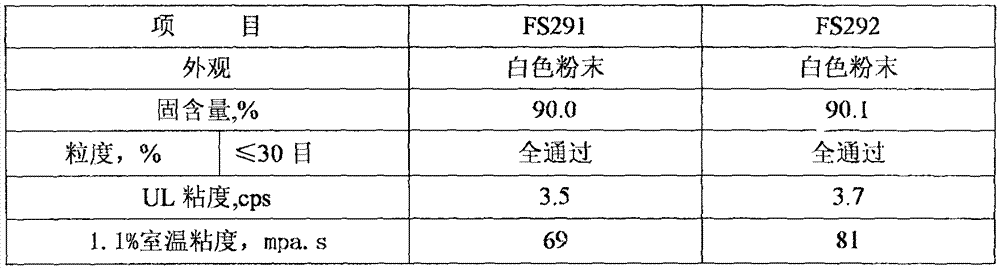

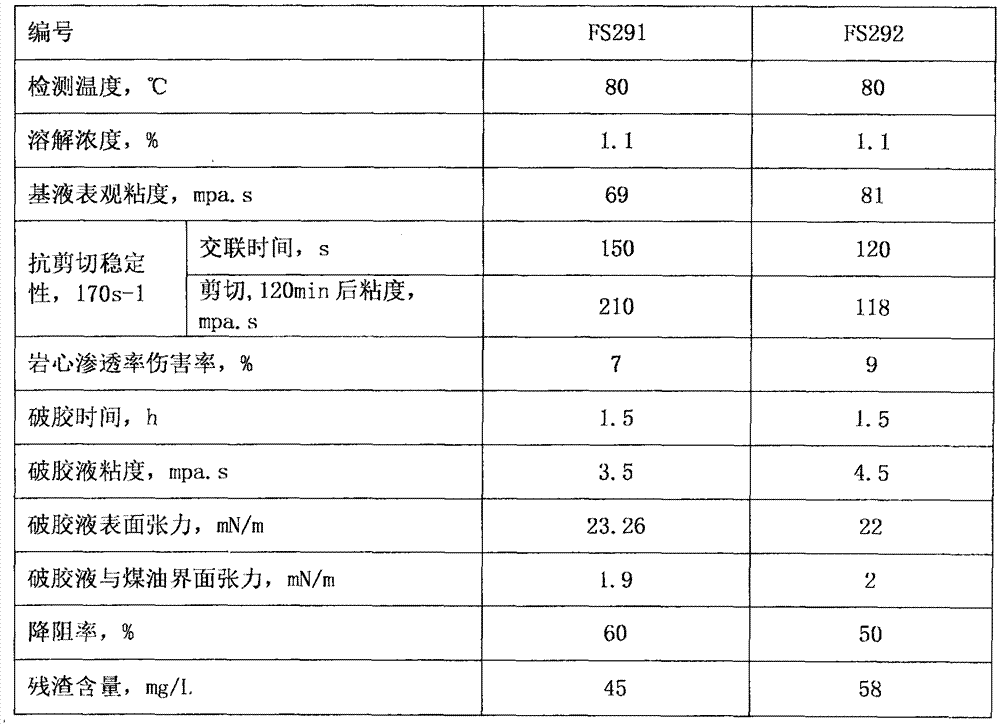

[0027] Polymerization of the solution: heating the solution to 40°C; adding 0.8% of thermal decomposition type and redox initiators accounting for the total mass of monomers at a certain speed; keeping the temperature at 40°C for 24 hours and then cooling down to room temperature. To obtain, the colloid is granulated, dried and pulverized to obtain a fracturing fluid thickener, which is r...

Embodiment 2

[0030] The weight percent of each monomer and water: AM:AA:PSNN:APEG:DMDAAC:MBA=450:150:80:0.5:20:0.04.

[0031] Solution preparation: Add 299.46g of distilled water into a 2000ml beaker, add 450g of AM monomer, 150g of AA monomer, add 80g of PSNN monomer, add 0.5g of APEG monomer, add 2g of DMDAAC monomer, add 0.04g of MBA monomer, Stir to dissolve for 30 minutes, and slowly add 40% NaOH solution under stirring condition to adjust the pH to 6-7. Continue to stir the solution for 20 min under the condition of feeding nitrogen gas at a certain flow rate to remove dissolved oxygen in water.

[0032] Polymerization of the solution: heating the solution to 40°C; adding 0.8% of thermal decomposition type and redox initiators accounting for the total mass of monomers at a certain speed; keeping the temperature at 40°C for 24 hours and then cooling down to room temperature. To obtain, the colloid is granulated, dried and pulverized to obtain a fracturing fluid thickener, which is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com