Preparation method for modified superfine low-oxygen water-atomized alloy powder used for diamond tool

A technology for diamond tools and alloy powder is applied in the field of preparation of modified ultra-fine low-oxygen water atomized alloy powder for diamond tools, which can solve the problems of low tool processing efficiency and high wear resistance, and achieve low oxygen content and service life. The effect of improving and improving the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

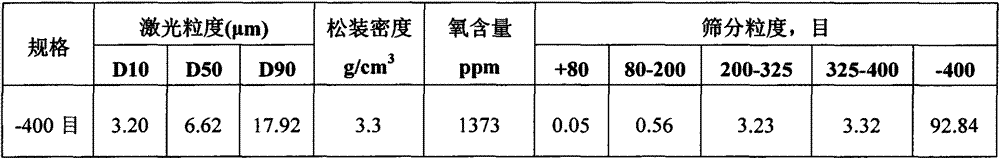

Embodiment approach 1

[0021] The order of adding raw materials is as follows:

[0022] Step 1: Add pure iron, insert a Ni plate in the middle of the pure iron, control the power at 230KW, and start melting.

[0023] The second step: when melting more than half, add Cu plate.

[0024] Step 3: Add Si and Sn ingots after the Cu plate is melted.

[0025] Step 4: Add Cr ingot, Ti plate, La and Y powder

[0026] After the raw materials are melted, cover the surface of the molten metal with lime. After 10 minutes, the lime melts and starts to remove slag. Measure the temperature of the melt. When the temperature reaches 1580°C, start the high-pressure water pump, fill the atomization barrel with nitrogen, adjust the atomization pressure to 100MPa, pour the melt into the middle leak bag and start atomization. The atomized water-powder mixture is sealed and pressurized in the powder-collecting tank, and a 1200-mesh filter cloth is installed at the water outlet at the bottom of the powder-collectin...

specific Embodiment approach 2

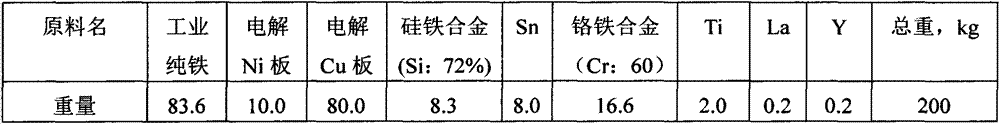

[0029] Use an intermediate frequency induction smelting furnace with a furnace capacity of 250kg for industrial production. The furnace lining is made of magnesia. The raw materials and weights used are as follows in Table 3:

Embodiment approach 2

[0031]

[0032] The order of adding raw materials is the same as Embodiment 1.

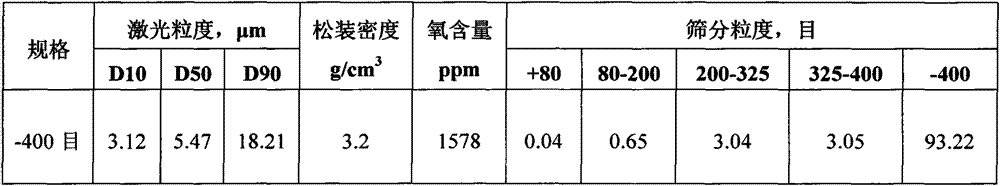

[0033]After the raw materials are melted, cover the surface of the molten metal with lime. After 10 minutes, the lime melts and starts to remove slag. Measure the temperature of the melt. When the temperature reaches 1600°C, start the high-pressure water pump, fill the atomization barrel with nitrogen, adjust the atomization pressure to 110MPa, pour the melt into the middle leak bag and start atomization. The atomized water-powder mixture is sealed and pressurized in the powder-collecting tank, and a 1200-mesh filter cloth is installed at the water outlet at the bottom of the powder-collecting tank, and the pressure is kept at 0.5 MPa until no obvious water-vapor mixture is discharged from the water outlet. First put the dehydrated wet powder into the dryer, seal the powder loading port, start the vacuum pump, start the power switch to make the dryer rotate vertically in one direction, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com