High-red-hardness tungsten carbide pure-phase block material and preparation method thereof

A bulk material, tungsten carbide technology, applied in the field of high red hardness tungsten carbide pure phase bulk material and its preparation, can solve the problems of reducing the red hardness of cemented carbide, difficult to densify, unable to refine grains, etc. The effect of improving high temperature mechanical properties, inhibiting grain growth, and excellent high red hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] Specifically, the present invention provides a method for preparing a high red hardness tungsten carbide pure-phase bulk material, which comprises the following steps:

[0024] (1) pre-pressing the nanometer tungsten carbide powder into a billet to obtain a pre-pressed billet;

[0025] (2) packaging and isolating the pre-pressed green body with a packaging material to obtain a precursor;

[0026] (3) vacuum purifying the precursor;

[0027] (4) Synthesizing a high red hardness tungsten carbide pure-phase bulk material at a temperature of at least 1000° C. and a pressure of at least 1.5 GPa.

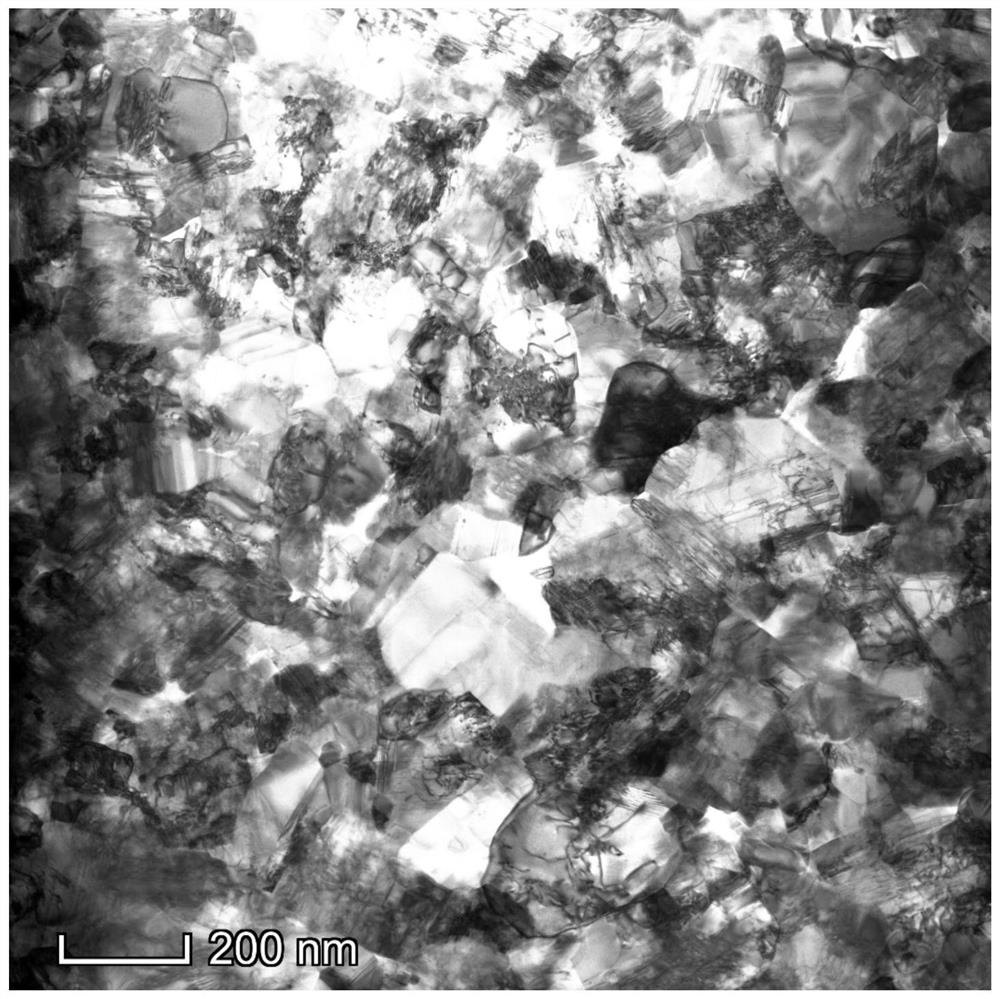

[0028] In step (1), it is preferable to use ultra-fine particle diameter and high-purity nano-tungsten carbide. In the method of this paper, tungsten carbide powder with higher purity and finer particle size is used as raw material, which is conducive to the final synthesis of high red hardness tungsten carbide pure phase bulk material with smaller average grain size and higher p...

Embodiment 1

[0073] 1) Calculate and weigh the nano-tungsten carbide powder with an average particle size of 40nm and a purity of ≥99.7%, put it into a shaping mold and pre-press it under a pressure of 25MPa to form a billet, and then use vanadium foil for packaging and isolation treatment to obtain a semi-dense clean surface precursor , the thickness of the foil is 0.03mm, and the density of the pre-pressed green body is 47%;

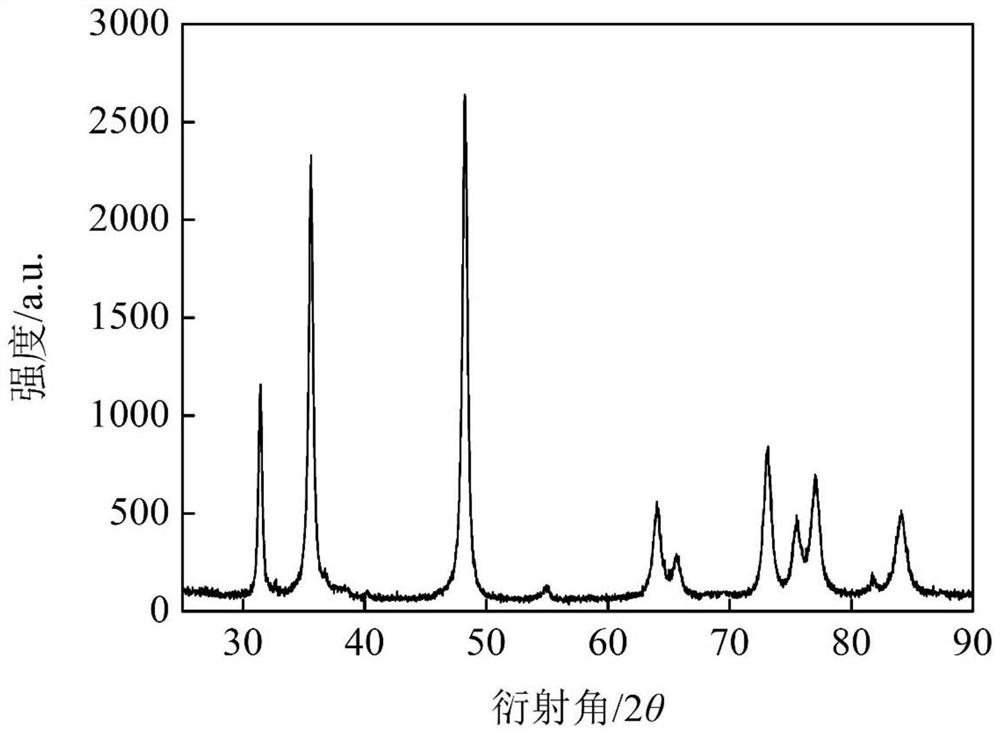

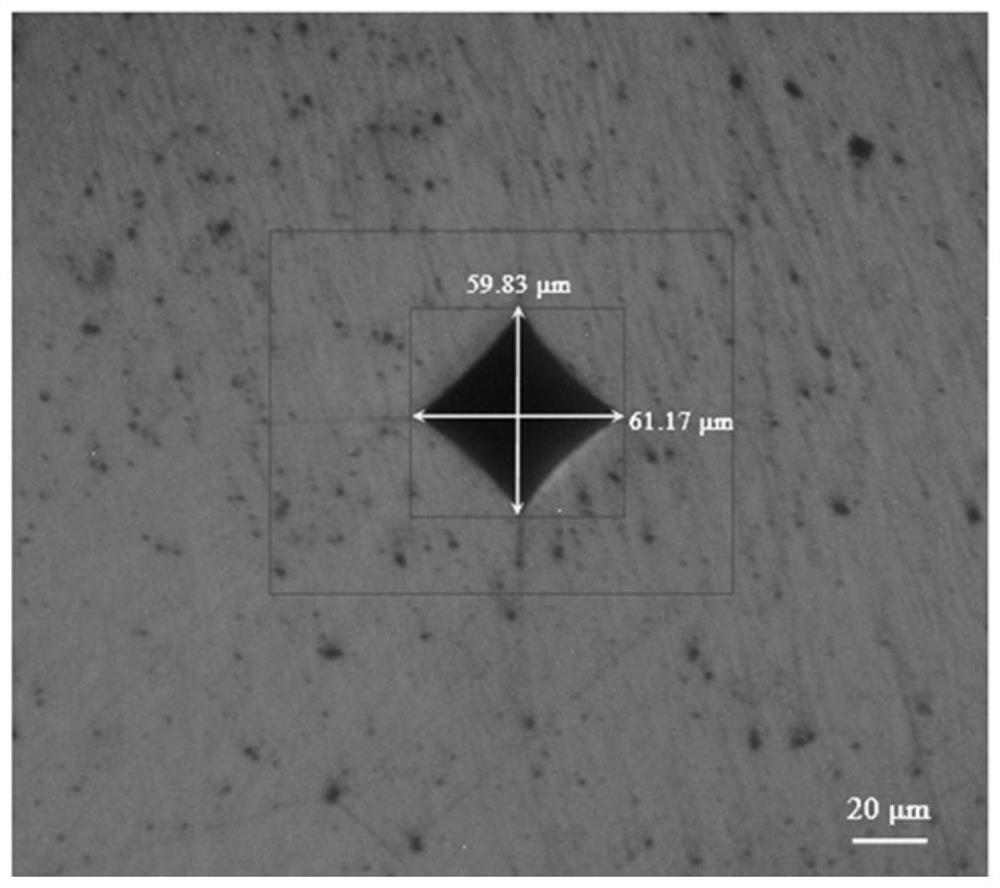

[0074] 2) Put the obtained precursor into the conductive thermal insulation and pressure transmission composite device, and place it in a high-temperature tube furnace for high-vacuum purification treatment. The treatment temperature is 900°C, the time is 30min, and the vacuum degree is -3 Pa, and finally completed the high-pressure synthesis in a six-way high-temperature and high-pressure equipment. The synthesis temperature is 1100°C, the pressure is 3GPa, the temperature rise / fall rate is 150°C / min, and the heat preservation and pressure holding time is 15min. Fin...

Embodiment 2

[0076] 1) Calculate and weigh nano-tungsten carbide powder with an average particle size of 240nm and a purity of ≥99.7%, put it into a shaping mold and pre-press it under a pressure of 15MPa to form a billet, and then use niobium foil for packaging and isolation treatment to obtain a semi-dense clean surface precursor , the thickness of the foil is 0.03mm, and the density of the pre-pressed green body is 55%;

[0077] 2) Put the obtained precursor into a conductive thermal insulation and pressure transmission compound device, and place it in a high-temperature tube furnace for high-vacuum purification treatment. The treatment temperature is 600°C, the time is 40min, and the vacuum degree is -3 Pa, and finally high-pressure synthesis was completed in a six-way high-temperature and high-pressure equipment. The synthesis temperature was 1200°C, the pressure was 4GPa, the temperature rising / falling rate was 260°C / min, and the heat preservation and pressure holding time was 20 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com