Powder cored wire for aluminum-based amorphous anti-corrosion coating

A powder core wire, amorphous technology, applied in the field of thermal spraying, can solve the problem of a lack of types and systems, and achieve the effect of excellent corrosion resistance and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

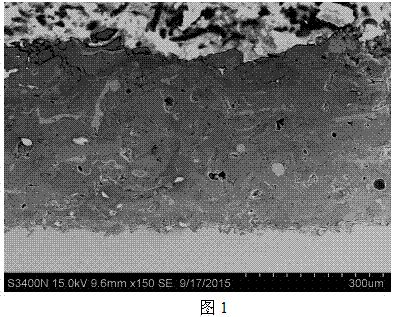

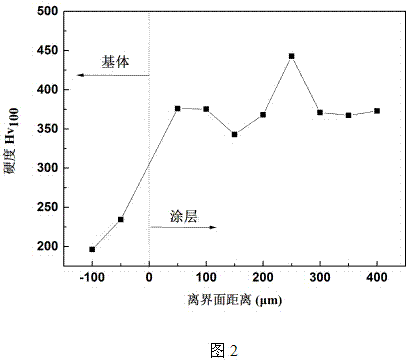

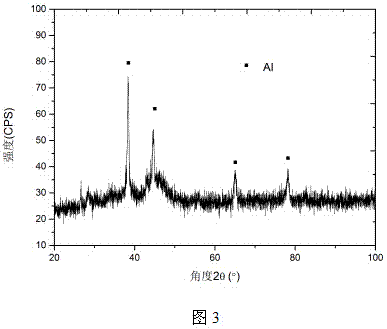

Image

Examples

Embodiment 1

[0020] Example 1: A powder core wire material for aluminum-based amorphous corrosion-resistant coating and its preparation method

[0021] Select a 10×0.3mm (width 10mm, thickness 0.3mm) pure aluminum strip, first tie it into a U shape, according to the atomic percentage of each element of the powder core wire material: 25at.%Ti, 8at.%Ni, 1at .% Re, the balance of Al, weigh the ingredients, put the taken powder into the powder mixer and mix for 60 minutes, then put the mixed powder into the U-shaped aluminum belt tank, the filling rate is 40%, and then put the U-shaped tank Close the mouth, wrap the powder in it, and then gradually reduce the diameter to Φ2mm through the wire drawing die, wind the finished wire into the disc shape required for the factory, and form a product that can be shipped after metering and packaging. It is prepared by high-speed arc spraying technology. The process parameters used in the coating: the spraying voltage is 32V, the spraying current is 140A...

Embodiment 2

[0023] Example 2: A powder core wire material for aluminum-based amorphous corrosion-resistant coating and its preparation method

[0024] Select a 10×0.3mm (width 10mm, thickness 0.3mm) pure aluminum strip, first tie it into a U shape, according to the atomic percentage of each element of the powder core wire material: 22at.%Ti, 9at.%Ni, 1.5 at.% Re, the balance of Al, weigh the ingredients, put the taken powder into the powder mixer and mix for 60 minutes, then put the mixed powder into the U-shaped aluminum belt tank, the filling rate is 44%, and then put the U-shaped The groove is closed to cover the powder in it, and then the diameter is gradually reduced to Φ2mm through the wire drawing die, and the finished wire is wound into the disc shape required for the factory, and the product that can be shipped is formed after metering and packaging. Using high-speed arc spraying technology Process parameters used for preparing the coating: the spraying voltage is 36V, the sprayi...

Embodiment 3

[0026] Example 3: A powder core wire material for aluminum-based amorphous corrosion-resistant coating and its preparation method

[0027] Select a 10×0.3mm (width 10mm, thickness 0.3mm) pure aluminum strip, first tie it into a U shape, according to the atomic percentage of each element of the powder core wire material: 20at.%Ti, 10at.%Ni, 2at .% Re, the balance of Al, weigh the ingredients, put the taken powder into the powder mixer and mix for 60 minutes, then put the mixed powder into the U-shaped aluminum belt tank, the filling rate is 48%, and then put the U-shaped tank Close the mouth, wrap the powder in it, and then gradually reduce the diameter to Φ2mm through the wire drawing die, wind the finished wire into the disc shape required for the factory, and form a product that can be shipped after metering and packaging. It is prepared by high-speed arc spraying technology. The process parameters used in the coating: the spraying voltage is 34V, the spraying current is 160...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com