Tower-type solar photo-thermal power generation system adopting fused salt working medium

A technology of photothermal power generation and solar heat collection, applied in the field of electric power, can solve the problems of sharp drop in overall efficiency, high cost of power generation, high tracking cost of heliostats, etc., to improve energy utilization, reduce construction period, and ensure Persistence and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

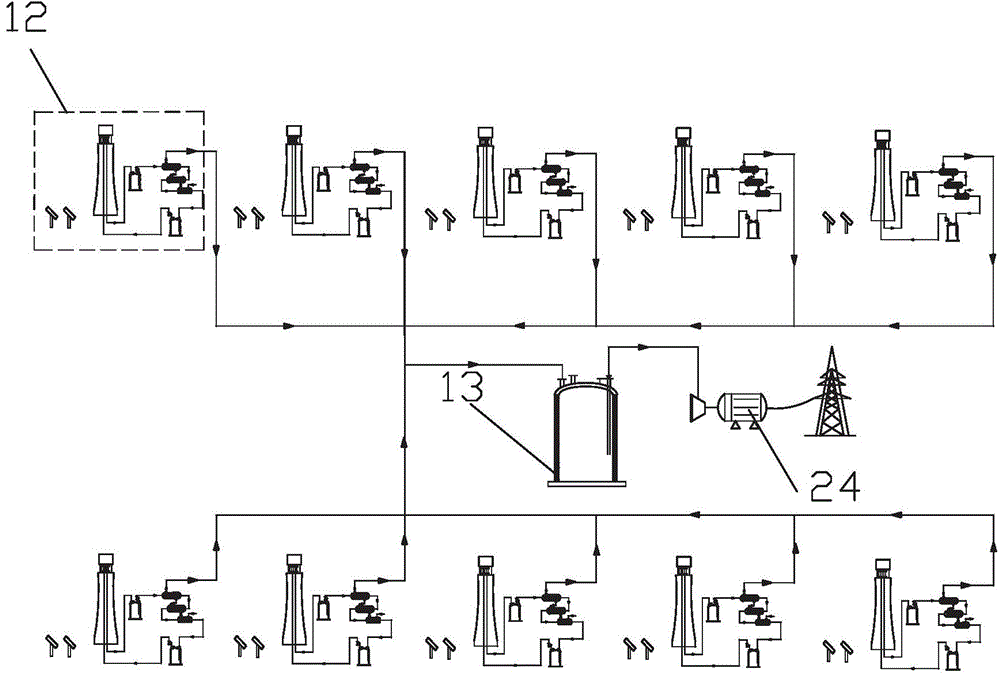

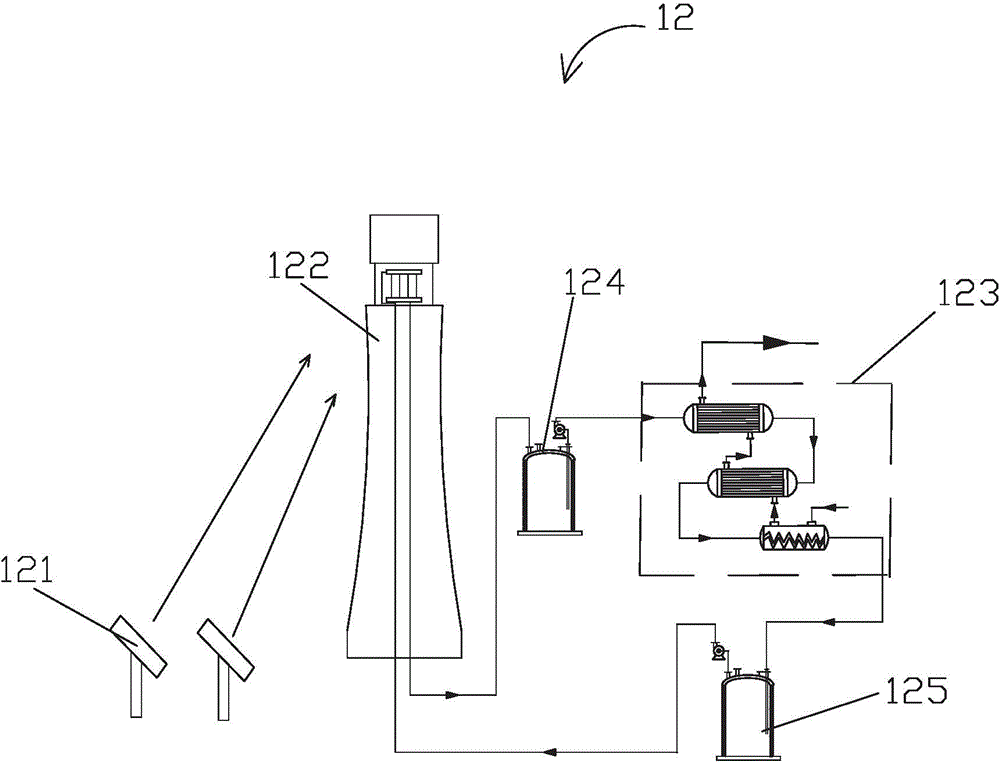

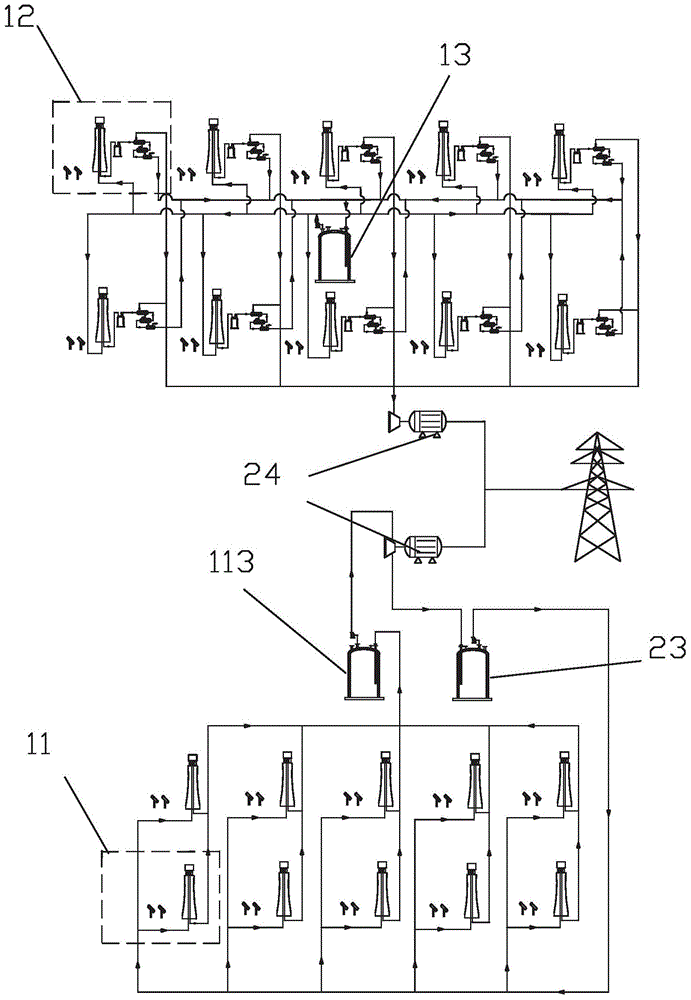

[0024] The principle of the tower-type solar thermal power generation system using molten salt working medium in the preferred embodiment of the present invention is as follows figure 1 As shown, it includes: a solar thermal collector for collecting solar heat, a heat exchanger connected with the solar thermal collector for generating superheated saturated steam, and a heat exchanger connected with the superheated saturated steam for converting superheated saturated steam into electrical energy The thermal power conversion device 24; the solar heat collection device includes a plurality of tower-type photothermal modules 11, 12 that collect solar heat energy; the plurality of tower-type photothermal modules 11, 12 include: using molten salt as a thermal medium, and Class B tower photothermal module 12 with distributed heat storage. Wherein, each B-type tower-type photothermal module 12 includes a second heliostat 121 for focusing sunlight, a second photothermal tower 122 provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com