Conducting film manufacturing method, touch control panel manufacturing method, and touch control panel

A production method and touch panel technology, which are applied in the manufacture of cables/conductors, conductive layers on insulating carriers, circuits, etc., to achieve the effects of reduced material usage, improved light transmittance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

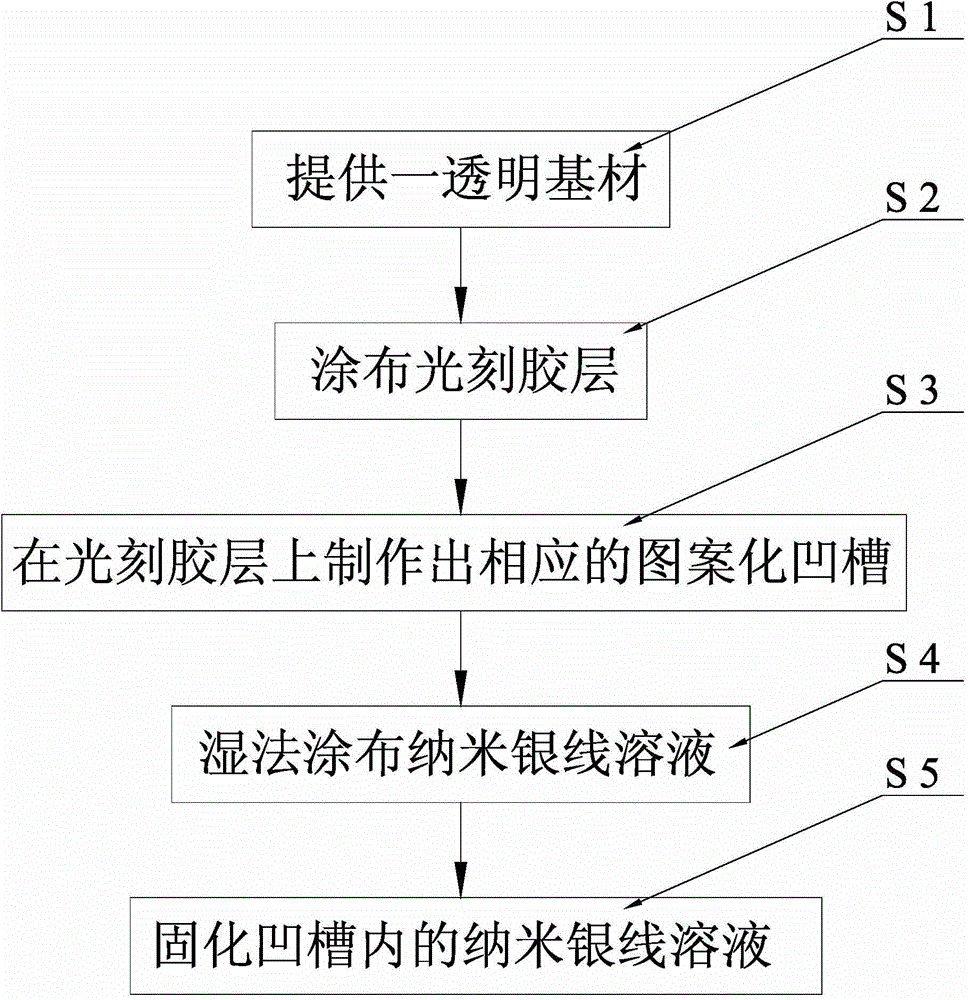

Method used

Image

Examples

Embodiment Construction

[0064] In order to make the purpose, technical solutions and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and implementation examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

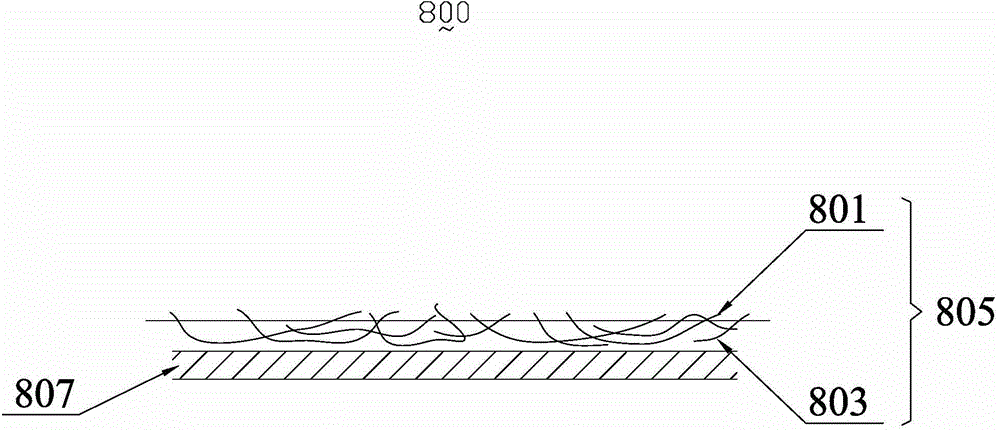

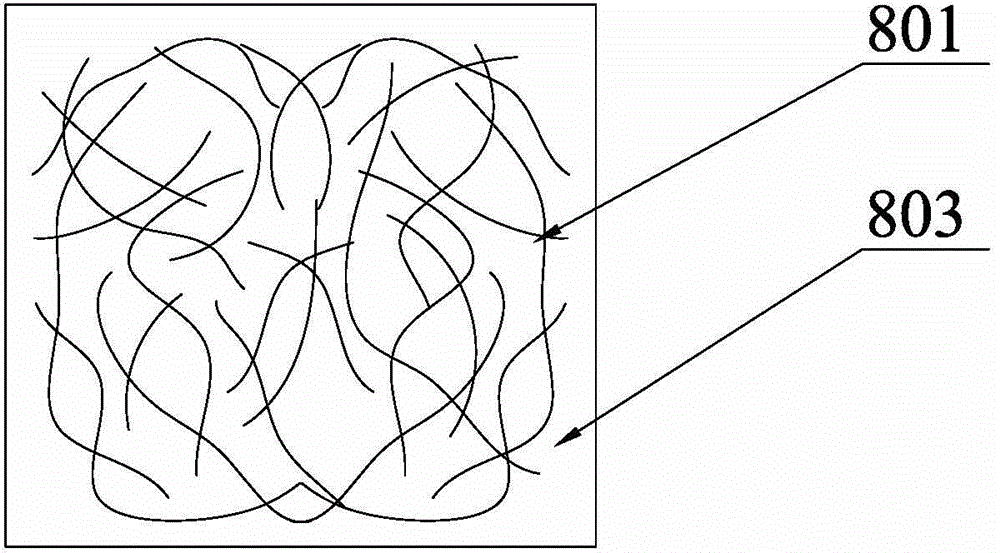

[0065] see figure 1 and figure 2 , is a cross-sectional schematic diagram of the silver nano wire conductive film 800, the silver nano wire film 805 is generally made on the substrate 807, including a plurality of silver nano wires 801 embedded in the matrix 803, and the silver nano wires 801 are arranged on the substrate 803 overlap each other to form a conductive network. The silver nanowires 801 (silvernanowires, SNW for short) have a wire length of 10 μm-300 μm, preferably 20 μm-100 μm, and preferably a length of 20 μm-50 μm, and the diameter (or line width) of the silver na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line length | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com