Tab laser welding structure of lithium ion battery

A lithium-ion battery and laser welding technology, which is applied in laser welding equipment, structural parts, welding equipment, etc., can solve the problems of complex driving conditions of new energy vehicles, single tab material, and large battery system weight. The effect of small deformation, fast welding speed and high joint quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 A tab laser welding structure of a lithium-ion battery, which mainly includes the following components:

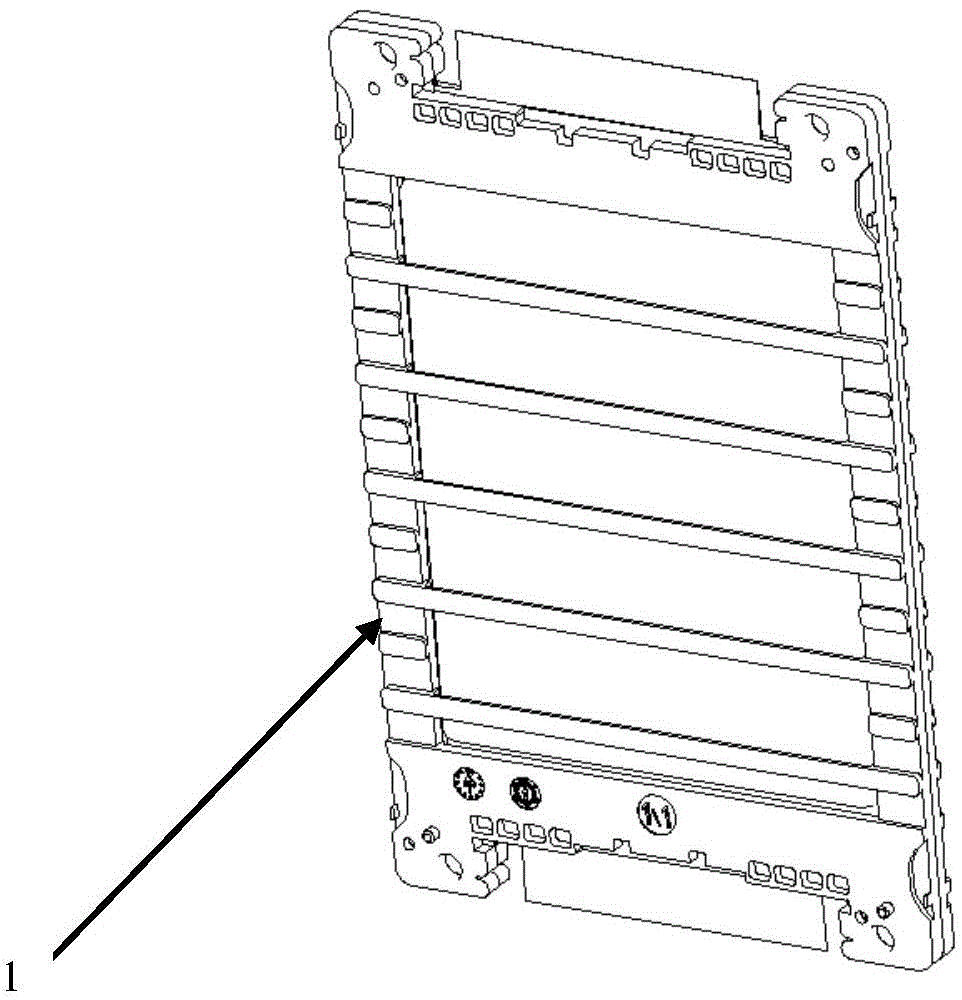

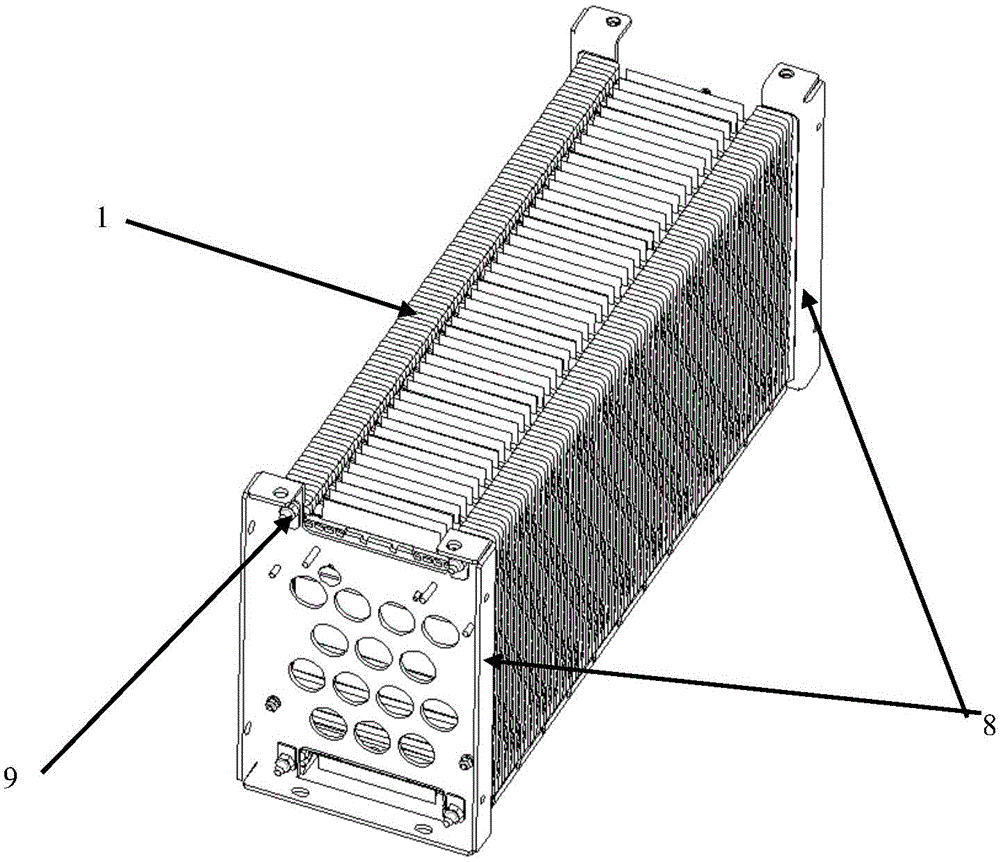

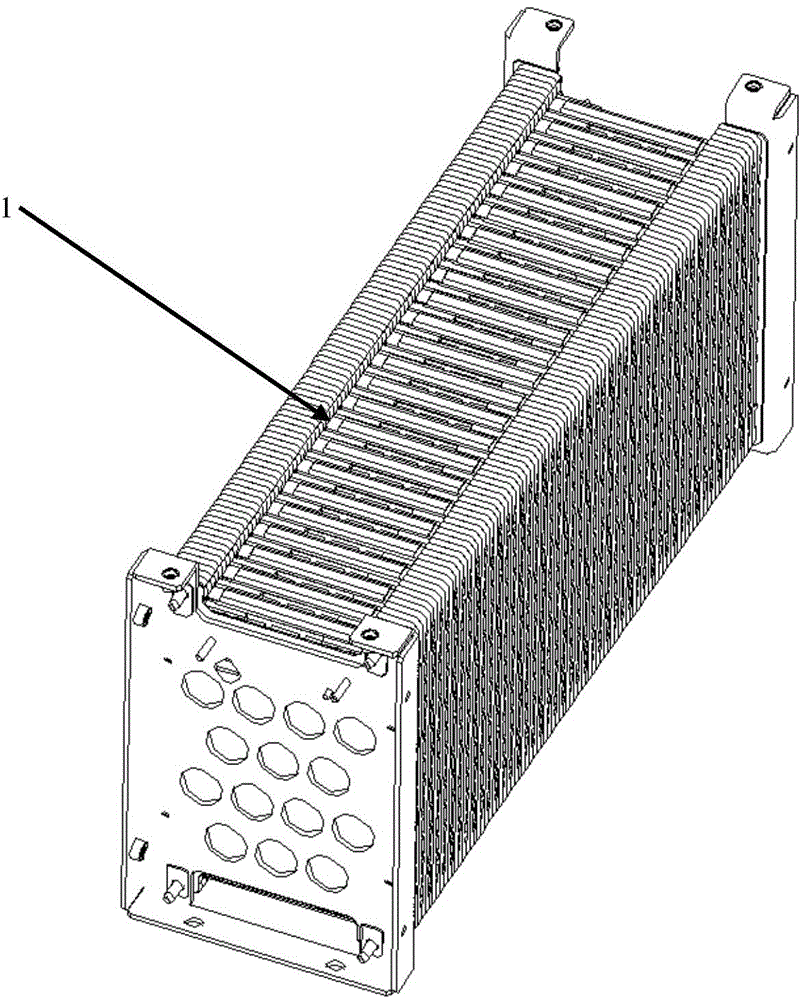

[0025] 1. Battery frame

[0026] 2. Square aluminum bar

[0027] 3. Collect the installation board

[0028] 4. Tab connection plate

[0029] 5. Tab lead-out board

[0030] 6. Tab lead-out plate backing plate

[0031] 7. Tab lead-out plate pressing plate

[0032] 8. End splint

[0033] 9. Screw rod

[0034] 10. Pole

[0035] Such as figure 1 As shown, two battery frames 1 are combined to build a single battery; 48 pairs of battery frames are connected in series with four screw rods 9, and two end splints 8 and lock nuts are used on the outside of the outermost battery frame. Lock bolts are clamped and fixed into groups, such as figure 2 shown. Install the upper aluminum bar 2 at the card slot formed between every two pairs of battery frames. In order to connect two single batteries in parallel, bend the tabs vertically at 90 degrees in the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com