Flexible and rigid composite busbar and manufacturing process

A technology of soft-hard composite and busbar, which is applied in the direction of coupling device, cable/conductor manufacturing, line/collector parts, etc., which can solve the problems of large inductance and poor safety of copper bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

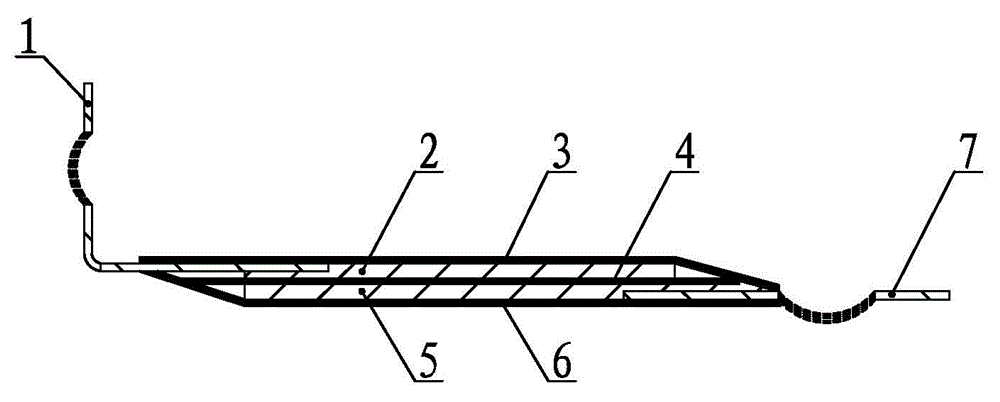

[0033] refer to figure 1 , there are two layers of copper plates, namely positive copper plate 2 and negative electrode copper plate 5, the size and thickness of the copper plate depends on the current passing through and the installation position of other components, usually the thickness is 0.8-10.0 mm, and the material is T2 Pure copper with semi-hardness, quarter-hardness or zero-hardness copper bars; copper plates are punched, bent, stretched, deburred, input / output terminals pressed, and welded with a thickness of 0.1 to 0.2 mm. Flexible copper bars 1 and 7 (also known as soft connections) made of one-hardness or zero-hardness copper foils, electroplating and other processes ensure that the input / output and external dimensions meet the requirements of connection and installation;

[0034] Between the positive electrode copper plate 2 and the negative electrode copper plate 5, a double-sided adhesive-containing insulating film 4 is used, that is, a film (such as PET) coat...

Embodiment 2

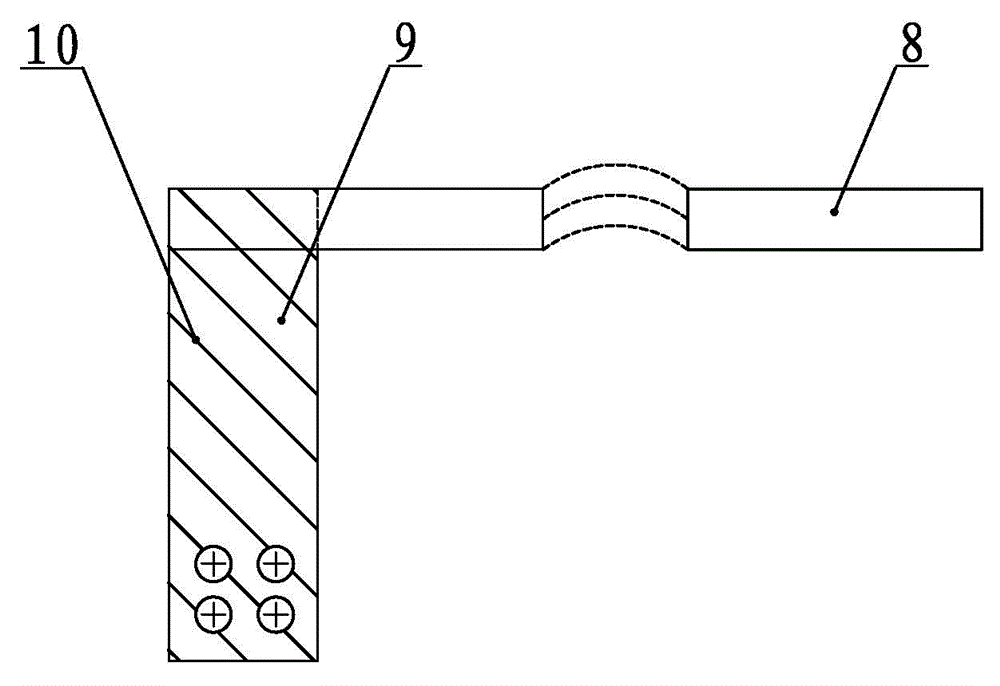

[0036] refer to figure 2 , is a single-layer flexible and rigid bus bar, which is connected together by copper plate 9 and flexible copper bar 8 by welding (such as silver welding, ultrasonic welding, tin welding, etc.), and the front and back of copper plate 9 are both made of single-layer The adhesive insulating film 10 is formed by thermally pressing and bonding a single layer of a film (such as PET) coated with a thermosetting epoxy resin adhesive.

Embodiment 3

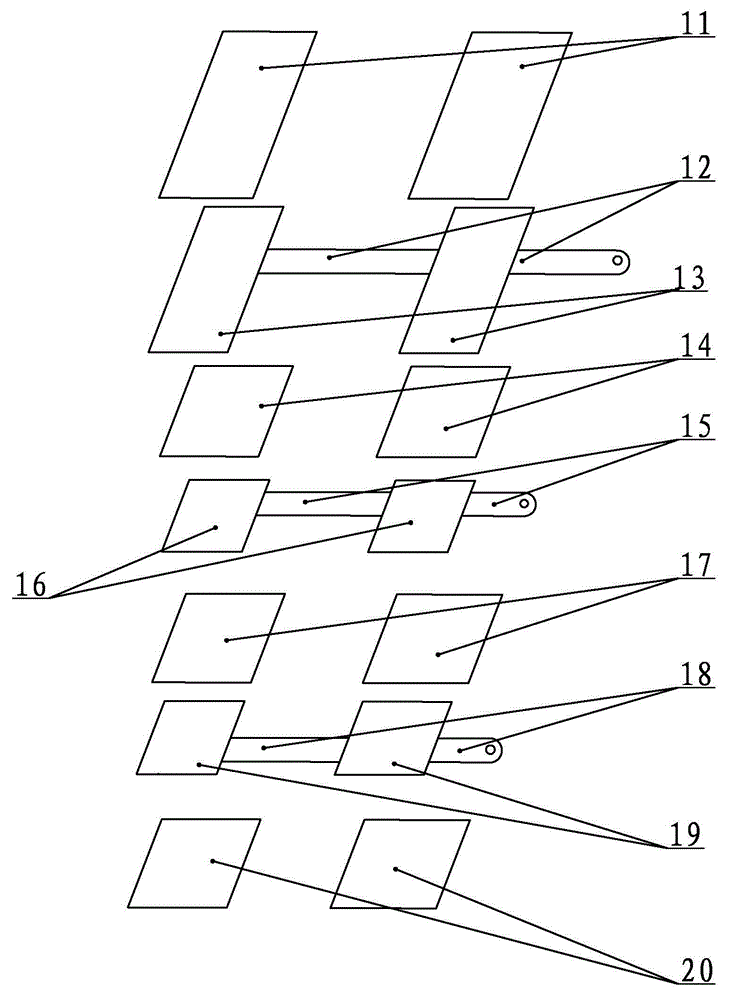

[0038] refer to image 3 , is a soft-hard composite bus bar, which includes multiple layers arranged in sequence, namely: single-sided adhesive insulating film 11, flexible copper bars 12 and copper plates 13 welded on the same layer, double-sided adhesive insulating film 14, and welded on the same layer Flexible copper bar 15 and copper plate 16, double-sided adhesive insulating film 17, flexible copper bar 18 and copper plate 19 welded on the same layer, and single-sided adhesive insulating film 20, and then put the above multi-layers in order according to the process requirements In the pressing mold, pressurize and heat in the hot press, and solidify the epoxy resin according to the pressurized heating, heat preservation and cooling curves, and form a soft-hard combination similar to printed circuit boards at room temperature after cooling. bus bar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com