Method for preparing CdS/MnWO4 heterojunction compound photo-catalyst

A technology of composite light and catalyst, applied in and transition fields, can solve problems such as low catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1 CdS / MnWO 4 Preparation of nanorods

[0018] The solution containing 1mmol of manganese chloride was added to the solution containing 1mmol of sodium tungstate, the pH of the mixed solution was adjusted to 9 with 1mmol / L sodium hydroxide solution, magnetically stirred, and then hydrothermally reacted at 180℃ for 24 hours , The precipitate obtained by centrifugal water washing, and drying at 60 ℃ to obtain manganese tungstate nanorods; take the prepared manganese tungstate nanorods and dissolve in deionized water, ultrasonically disperse, add equimolar thiourea and under stirring conditions Cadmium acetate, control the molar ratio of cadmium acetate to manganese tungstate to 0.3, 0.5, 0.7, 1.1 and 1.5 respectively. After stirring and mixing uniformly, proceed to hydrothermal reaction at 180°C for 24 hours, and use the resulting yellow product Wash with ionized water and ethanol, filter, and dry in a constant temperature drying box at 60°C.

Embodiment 2

[0019] Example 2CdSMnWO 4 / MnWO 4 Characterization and Analysis of Heterojunction Composite Photocatalyst

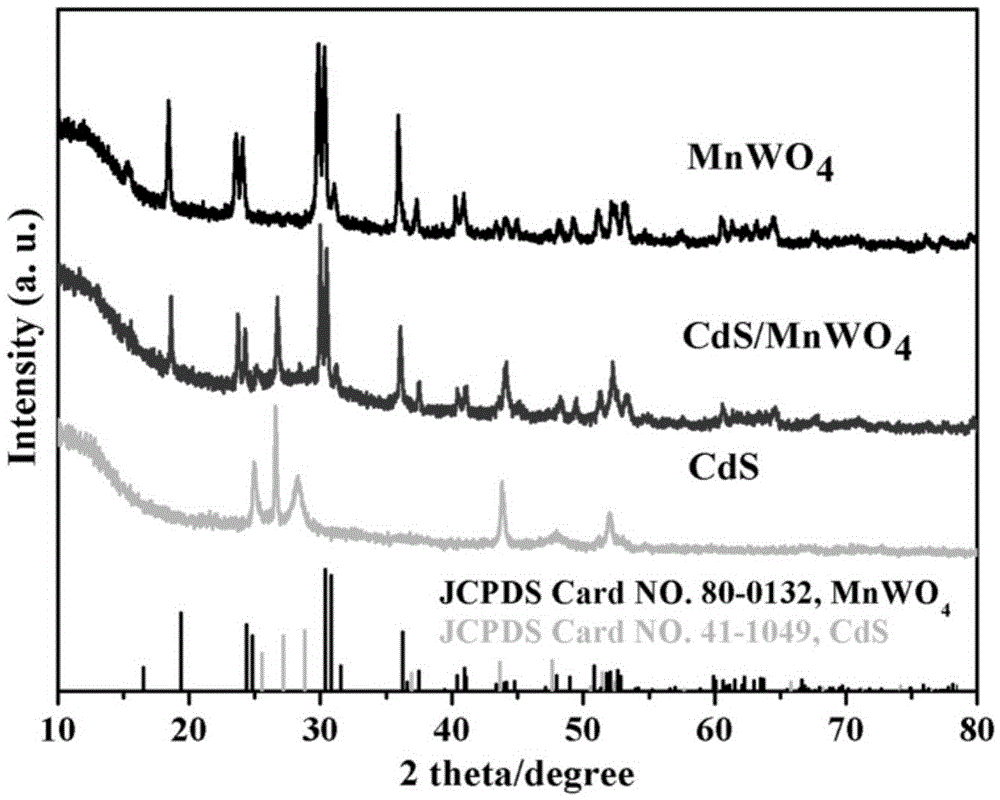

[0020] Such as figure 1 As shown, it can be seen from the figure that the composite sample has both CdS and MnWO 4 The characteristic peaks indicate that we have successfully prepared CdS / MnWO 4 Heterojunction composite photocatalyst.

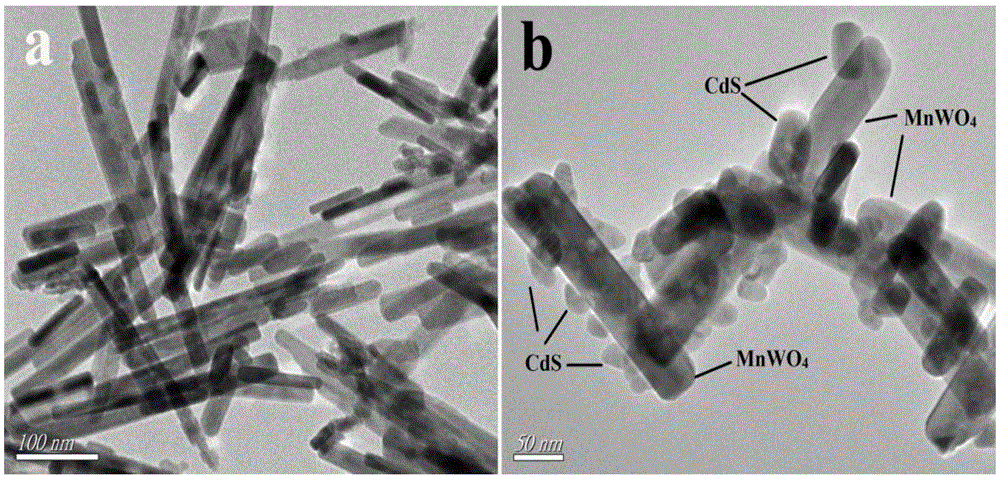

[0021] Such as figure 2 As shown, the pure MnWO can be seen in the picture (A) 4 It is a nanorod. In the picture (B), you can see the existence of CdS nanoparticles. The size of the nanoparticles is 10-30nm, and they are loaded on MnWO. 4 On the nanorod.

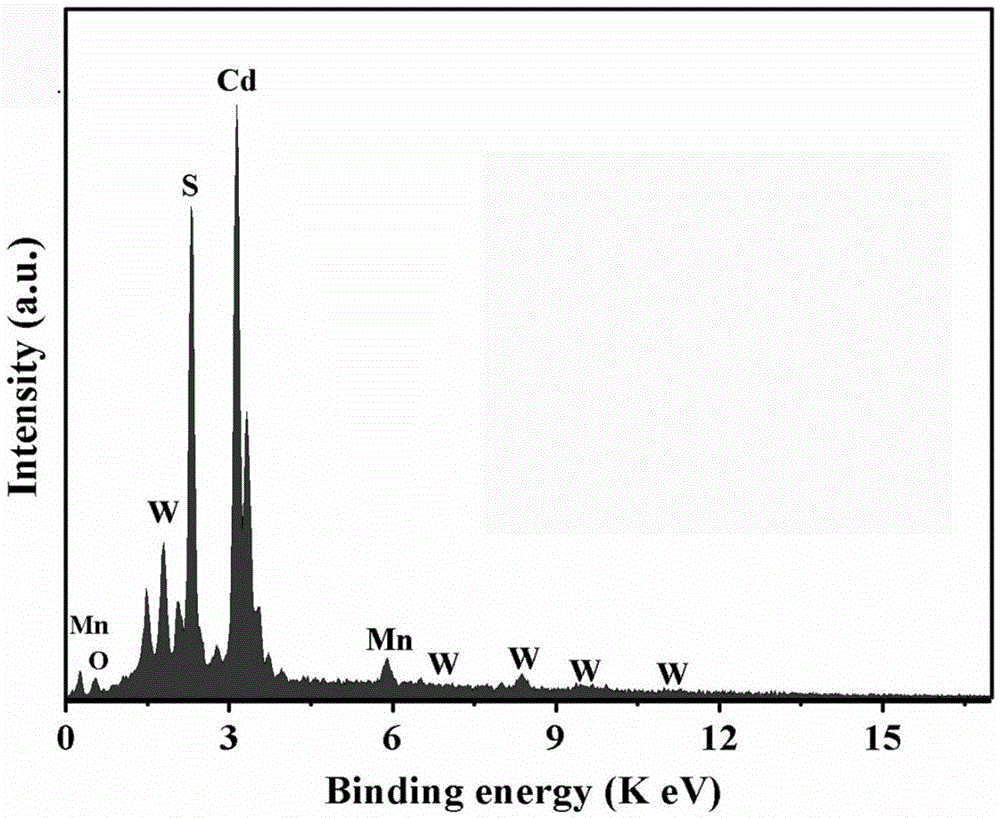

[0022] Such as image 3 As shown, the spectrum shows the presence of manganese, tungsten, sulfur, cadmium, and oxygen.

[0023] Such as Figure 4 As shown in the figure, the impedance difference between cadmium sulfide, manganese tungstate, cadmium sulfide and manganese tungstate heterojunction can be clearly seen.

Embodiment 3

[0024] Example 3 CdS / MnWO 4 Visible light catalytic activity experiment of heterojunction composite photocatalyst

[0025] (1) Prepare a methylene blue or methyl violet solution with a concentration of 10 mg / L, and place the prepared solution in a dark place.

[0026] (2) Weigh CdS / MnWO 4 Heterojunction composite photocatalyst 100mg (when CdS and MnWO 4 The molar ratio of 0.3:1, 0.5:1, 0.7:1, 1:1, 1.5:1 and the samples obtained are denoted as CdS-1, CdS-2, CdS-3, CdS-4, CdS-5), Placed in the photocatalytic reactor respectively, add 100mL of the target degradation solution prepared in step (1), magnetically stir for 30min after the composite photocatalyst is evenly dispersed, turn on the water source and light source, and perform the photocatalytic degradation experiment.

[0027] (3) Aspirate the photocatalytic degradation liquid in the reactor every 10 minutes, and use it for the measurement of UV-visible absorbance after centrifugation.

[0028] (4) by Figure 5 It can be seen that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com