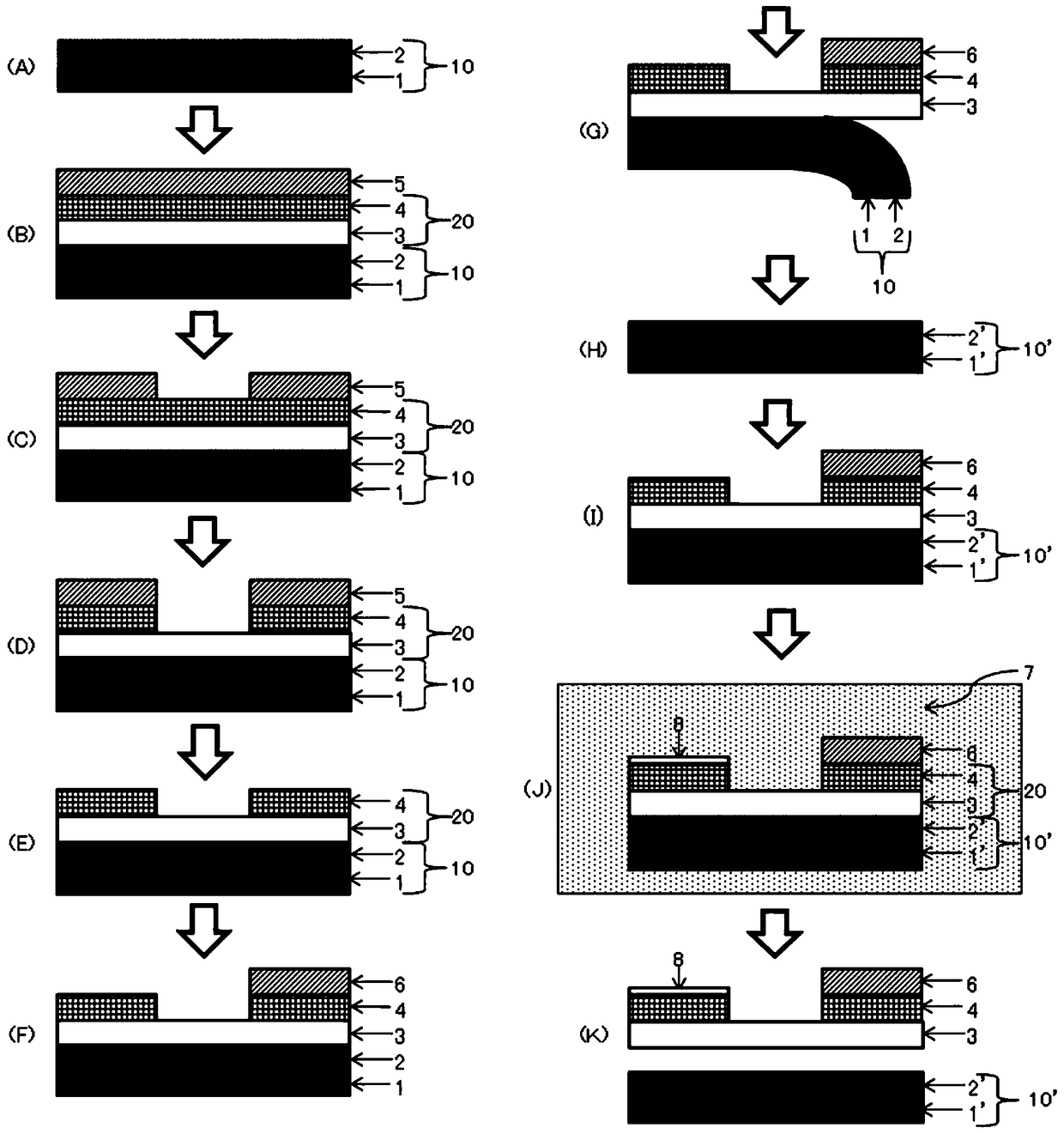

Support film for wiring board manufacturing process

A wiring substrate and supporting film technology, applied in lamination devices, lamination, layered products, etc., can solve the problems of complicated supporting films, damaged wiring substrates, inability to completely peel off and remove, etc., and achieve simple peeling. removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

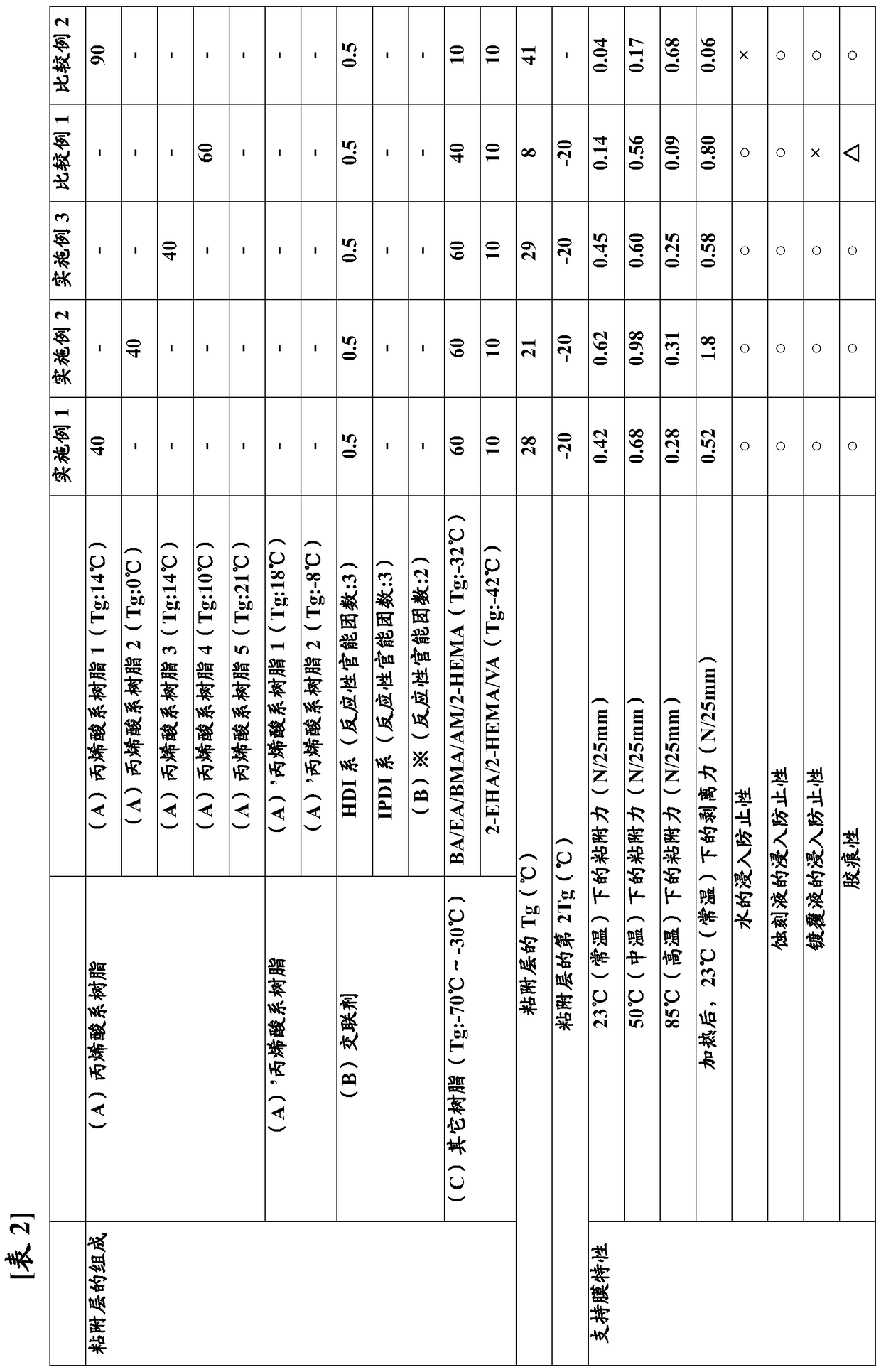

[0063] Hereinafter, the present invention will be further described in detail based on examples. It should be noted that, in the present examples, "parts" and "%" are based on mass unless otherwise specified.

[0064] [Example and Comparative Example]

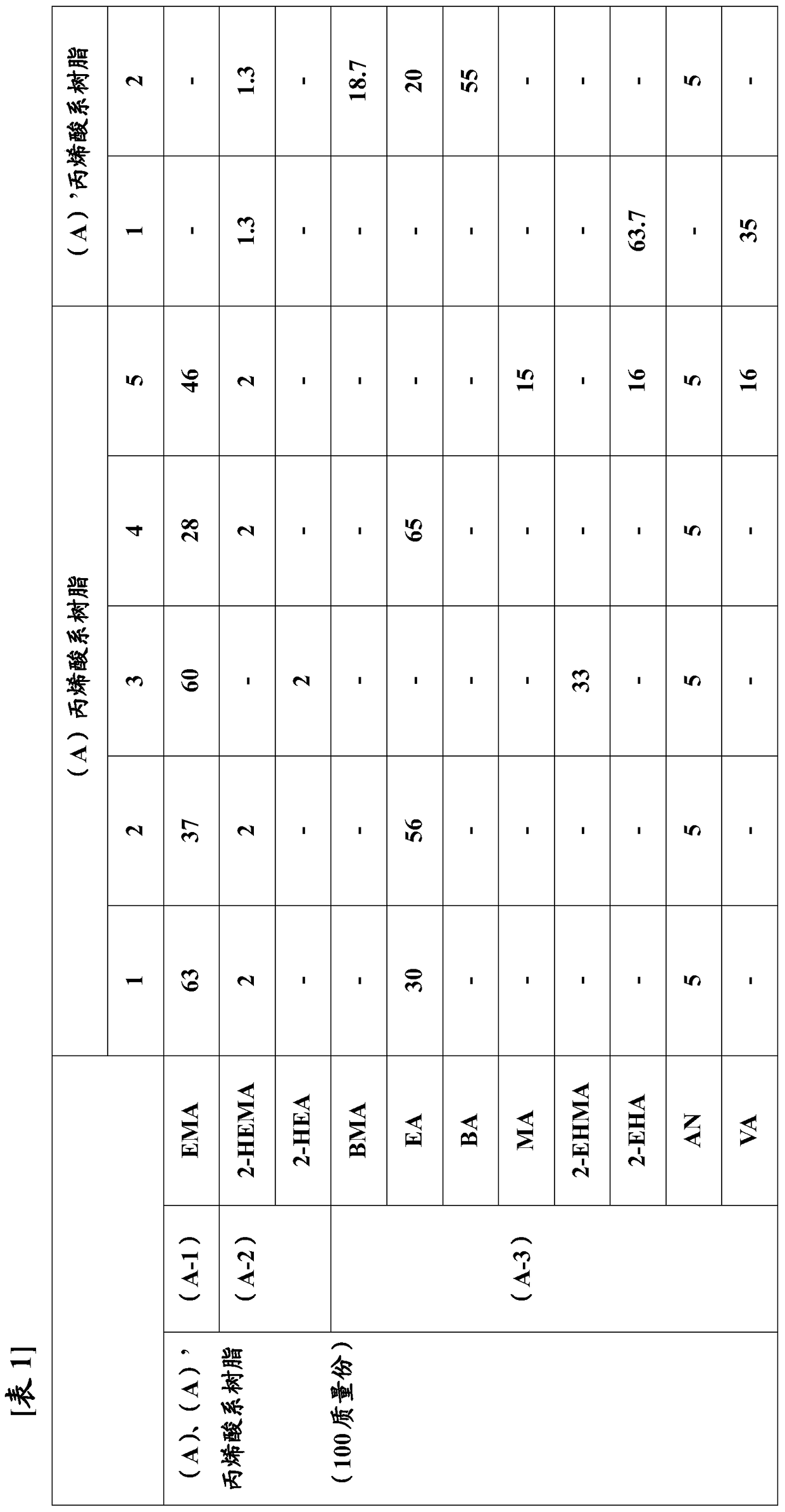

[0065] 1. (A) Synthesis of acrylic resin

[0066] In a reaction vessel equipped with a stirrer, a capacitor, a thermometer, and a nitrogen introduction tube, use ethyl acetate as a solvent, mix the monomer components shown in Table 1 and 0.15 parts of azobisisobutyronitrile, stir until uniform, and then Bubbling was performed at a flow rate of 100 ml / min for 60 minutes to degas the dissolved oxygen in the reaction system. Next, the temperature was raised to 80° C. over 1 hour, and after the temperature was raised, polymerization was performed for 4 hours. Thereafter, the temperature was raised to 90° C. over 1 hour, and further kept at 90° C. for 1 hour, and then cooled to room temperature. Next, toluene was added and adjus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com