Preparation technology for integrally molded PC (polycarbonate) case

A preparation process and box body technology, which is applied in the field of one-time molding PC box preparation, can solve the problems of difficult PC materials and undisclosed PC bags, etc., and achieve the effects of enhanced fluidity, low density, and easy portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

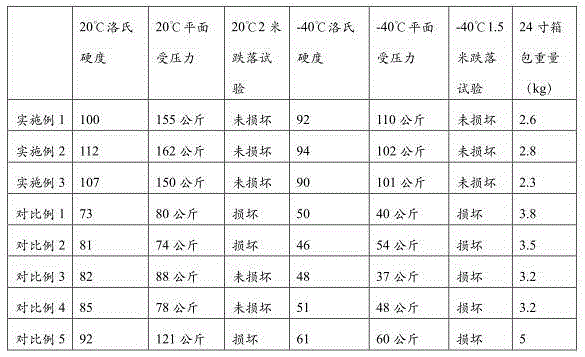

Examples

Embodiment 1

[0029] Step 1: After drying the PC material, it is worth drying the PC material;

[0030] Step 2: Prepare the coloring material, mix it thoroughly first, and then dry it to obtain the coloring material;

[0031] Step 3: Calculate 1000 parts by weight of the PC material in step 1, 10 parts of styrene-acrylamide copolymer, 0.7 parts of zirconium phosphate, 1 part of hydrotalcite, 1 part of zinc borate, 3 parts of zirconium borate, after fully stirring Then add 5 parts of blending ingredients in step 2, and fully stir to obtain the PC raw material;

[0032] Step 4: Add the PC raw material obtained in Step 3 into the mold with a high-speed injection molding machine and inject it directly into a box. The speed of the high-speed injection molding machine is 150r / min, the temperature is 100°C, and the injection molding time is 5-15 seconds;

[0033] Step 5: Cover the box obtained in Step 4 with a PE protective film;

[0034] Step 6: Dehumidify the box body obtained in Step 5 and pa...

Embodiment 2

[0036] Step 1: After drying the PC material, it is worth drying the PC material;

[0037] Step 2: Prepare the coloring material, mix it thoroughly first, and then dry it to obtain the coloring material;

[0038] Step 3: Calculate 1500 parts by weight of the PC material in step 1, 3 parts of styrene-acrylamide copolymer, 0.5 parts of zirconium phosphate, 2 parts of hydrotalcite, 0.5 parts of zinc borate, 1 part of zirconium borate, after fully stirring Then add 5 parts of blending ingredients in step 2, and fully stir to obtain the PC raw material;

[0039] Step 4: The PC raw material obtained in Step 3 is injected into the mold by a high-speed injection molding machine and directly injected into a box body. The speed of the high-speed injection molding machine is 200r / min, the temperature is 160°C, and the injection molding time is 10 seconds;

[0040] Step 5: Cover the box obtained in Step 4 with a PE protective film;

[0041] Step 6: Dehumidify the box body obtained in Ste...

Embodiment 3

[0043] Step 1: After drying the PC material, it is worth drying the PC material;

[0044] Step 2: Prepare the coloring material, mix it thoroughly first, and then dry it to obtain the coloring material;

[0045] Step 3: Calculate 2000 parts by weight of PC material in step 1, 7 parts of styrene-acrylamide copolymer, 1.5 parts of zirconium phosphate, 3 parts of hydrotalcite, 1.5 parts of zinc borate, 2 parts of zirconium borate, after fully stirring Then add 5 parts of blending ingredients in step 2, and fully stir to obtain the PC raw material;

[0046] Step 4: The PC raw material obtained in Step 3 is injected into the mold by a high-speed injection molding machine and directly injected into a box body. The speed of the high-speed injection molding machine is 170r / min, the temperature is 200°C, and the injection molding time is 15 seconds;

[0047] Step 5: Cover the box obtained in Step 4 with a PE protective film;

[0048] Step 6: Dehumidify the box body obtained in Step 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com