A kind of high-fullness environment-friendly interior wall paint and preparation method thereof

An interior wall coating, cellulose ether technology, used in coatings, latex paints, etc., can solve the problems of dryness, low fullness, and poor leveling of the paint film, and achieve excellent water resistance, good flow performance, and low rigidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

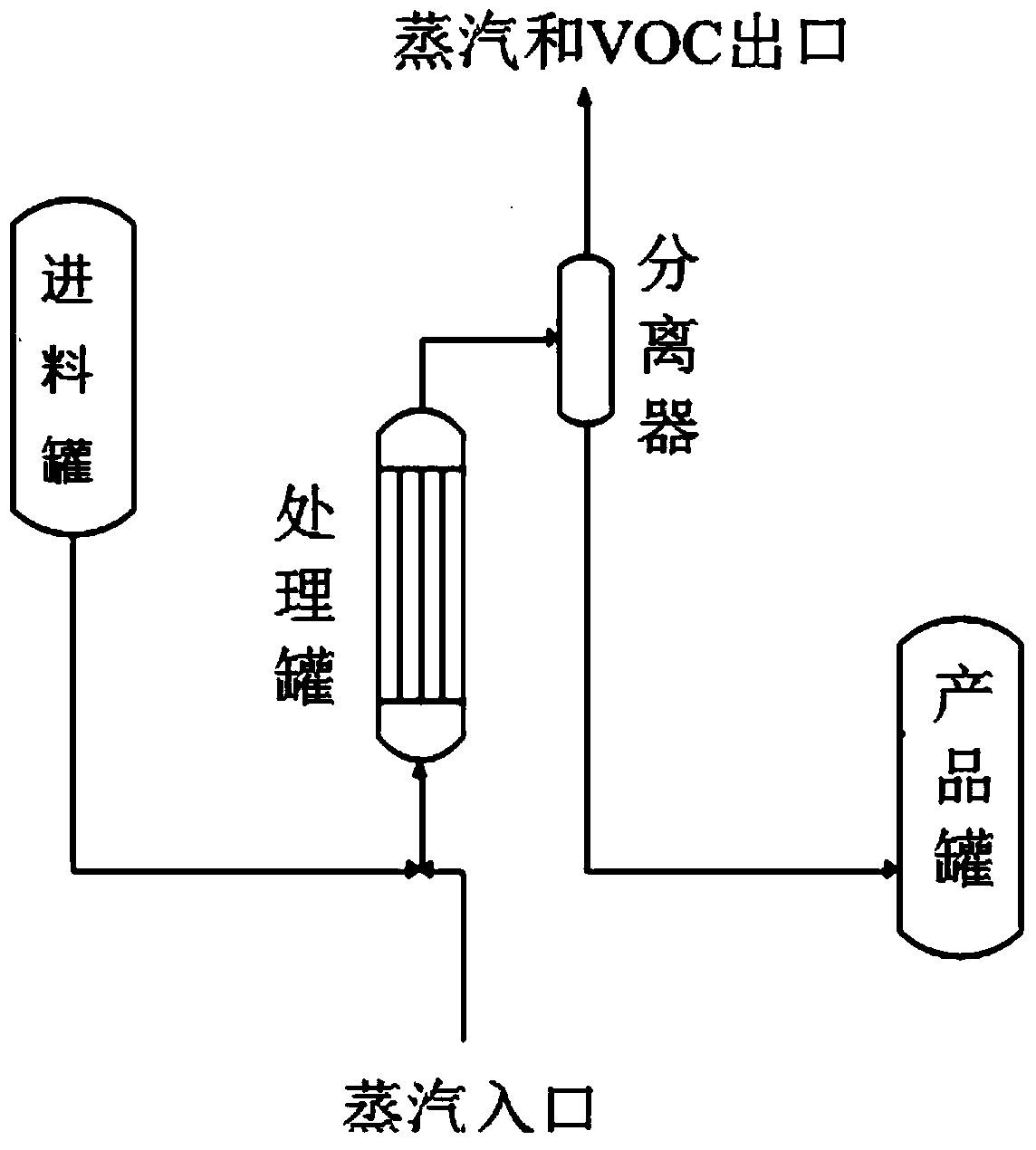

Method used

Image

Examples

Embodiment 1

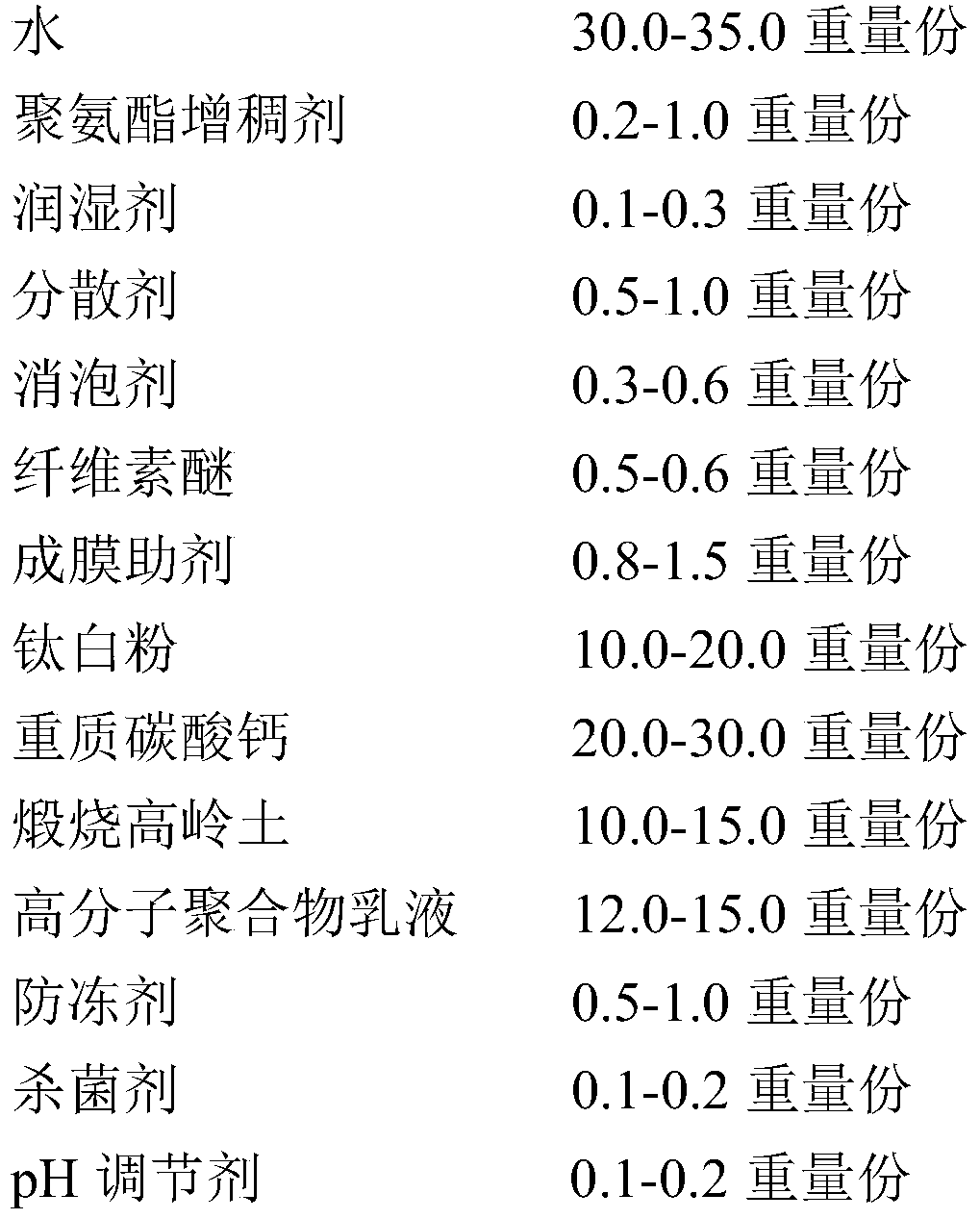

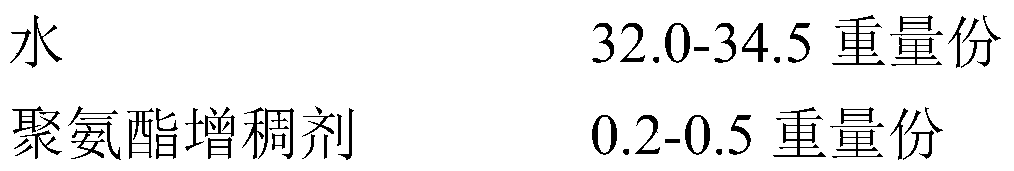

[0041] First take the following components of the coating formula of the present invention in the following weight ratios: 34.5 parts of water, cellulose ether (Natrosol TM 250MHBR) 0.6 parts, pH regulator (AMP-95) 0.2 parts, wetting agent (EH-9) 0.2 parts, dispersant ( B 03) 0.5 parts, defoamer ( CF 439) 0.4 parts, coalescent (TEXANOL) 1.1 parts, antifreeze (ethylene glycol) 0.6 parts, polyurethane thickener (Aquaflow TM NHS-300) 0.2 parts, polymer emulsion (LV-380VF) 12.5 parts, fungicide (ROCIME 631) 0.2 parts, rutile titanium dioxide (R-996) 12.0 parts, ground calcium carbonate (GF110) 25.0 parts 12.0 parts of calcined kaolin (DG-80). Then proceed as follows:

[0042] Add 34.5 parts of water, 0.6 parts of cellulose ether, and 0.2 parts of pH regulator into the dispersing tank in turn under low-speed stirring conditions of 500 rpm to form a mixture;

[0043] Under low-speed stirring at 500 rpm, add 0.2 parts of wetting agent, 0.5 parts of dispersing agent, 0.2 parts o...

Embodiment 2

[0049] The preparation method of high-fullness interior wall environmental protection paint of the present invention, at first take by weight the following components of the paint formula of the present invention: 32.7 parts of water, cellulose ether (Natrosol TM 250MHBR) 0.57 parts, pH regulator (AMP-95) 0.2 parts, wetting agent (EH-9) 0.2 parts, dispersant ( B 03) 0.5 parts, defoamer ( CF 439) 0.5 parts, coalescent (TEXANOL) 1.2 parts, antifreeze (ethylene glycol) 0.6 parts, polyurethane thickener (Aquaflow TM NHS-300) 0.33 parts, polymer emulsion (LV-380VF) 13.0 parts, fungicide (ROCIME 631) 0.2 parts, rutile titanium dioxide (R-996) 14.0 parts, ground calcium carbonate (GF110) 23.0 parts 13.0 parts of calcined kaolin (DG-80). Then proceed as follows:

[0050] Add 32.7 parts of water, 0.57 parts of cellulose ether, and 0.2 parts of pH regulator into the dispersion tank in sequence under low-speed stirring at 500 rpm to form a mixture;

[0051] Under low-speed stirring...

Embodiment 3

[0057] The preparation method of high-fullness interior wall environmental protection paint of the present invention, at first take by weight the following components of the paint formula of the present invention: 34.47 parts of water, cellulose ether (Natrosol TM 250MHBR) 0.58 parts, pH regulator (AMP-95) 0.2 parts, wetting agent (EH-9) 0.2 parts, dispersant ( B 03) 0.5 parts, defoamer ( CF 439) 0.4 parts, coalescence aid (TEXANOL) 1.1 parts, antifreeze agent (ethylene glycol) 0.6 parts, polyurethane thickener (RM-2020) 0.25 parts, polymer emulsion (LV-380VF) 12.5 parts , 0.2 parts of fungicide (ROCIME 631), 12.0 parts of rutile titanium dioxide (R-996), 24.0 parts of ground calcium carbonate (GF110), 13.0 parts of calcined kaolin (DG-80). Then proceed as follows:

[0058] Add 34.47 parts of water, 0.58 parts of cellulose ether, and 0.2 parts of pH regulator into the dispersion tank in sequence under low-speed stirring at 500 rpm to form a mixture;

[0059] Under low-spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com