Production method of hygroscopic polyester fiber

A technology of polyester fiber and manufacturing method, applied in the field of polyester fiber manufacturing, can solve problems such as no progress, and achieve the effects of excellent fiber physical properties, sufficient wearing comfort, and good spinnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

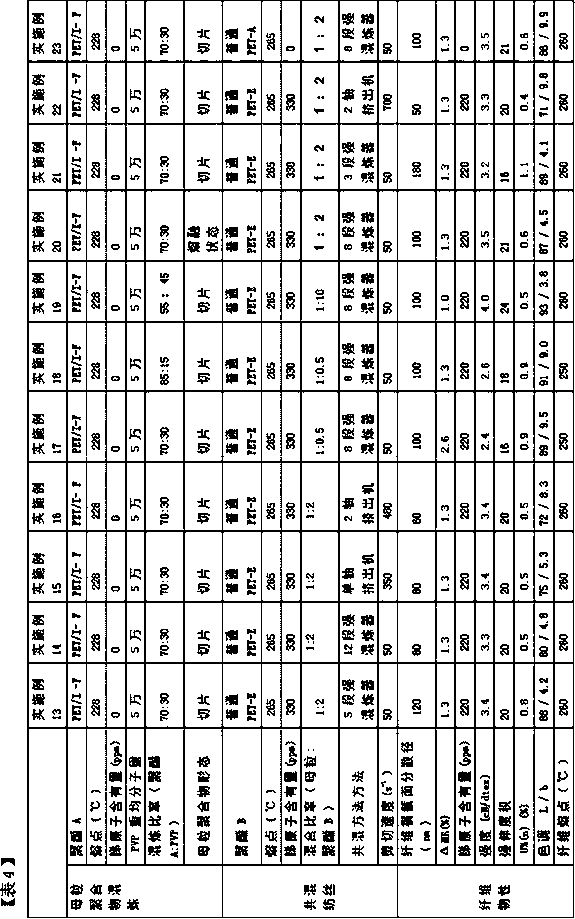

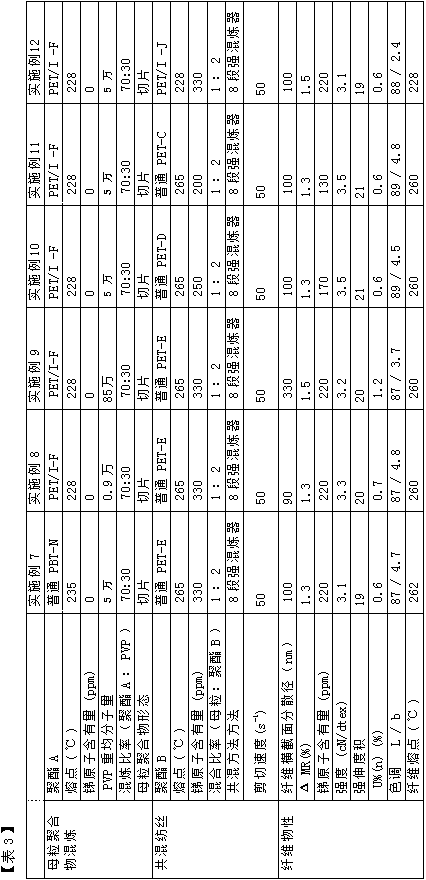

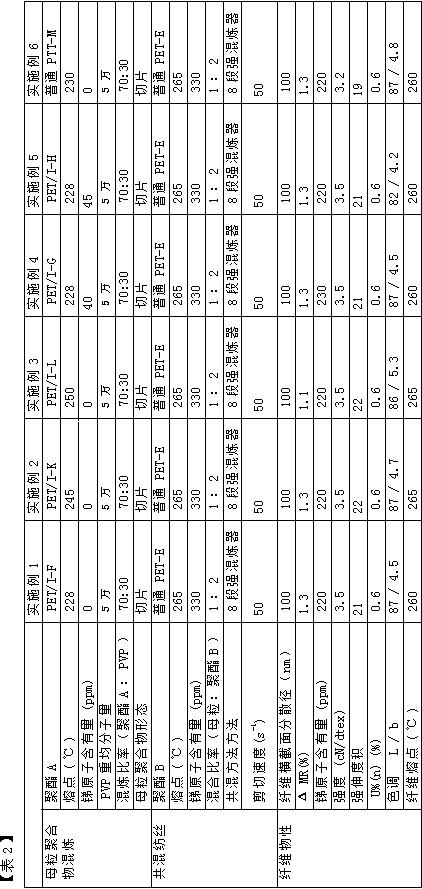

Examples

manufacture example 1

[0085] 784 g of ethylene glycol, 993 g of terephthalic acid, and 331 g of isophthalic acid were subjected to esterification reaction, followed by polycondensation reaction. First, add all the terephthalic acid and isophthalic acid, 533g of ethylene glycol, 1.2g of calcium acetate, and 0.88g of tetrabutyl titanate into the reactor with a rectification tower, and heat up from 130°C to 235°C for reaction After 3 hours, after the transesterification reaction was completed, 0.57 g of methyl trimellitic acid was added. Then move to the polycondensation reactor, and the temperature is raised from 240°C to 285°C under vacuum for post-condensation reaction for 4 hours.

manufacture example 2

[0086] [Manufacturing example 2]

[0087] Use antimony trioxide (0.45g) instead of tetrabutyl titanate as the reaction catalyst, and the others are the same as in Production Example 1.

manufacture example 3

[0088] [Manufacturing example 3]

[0089] 784 g of ethylene glycol and 1,324 g of terephthalic acid were subjected to esterification reaction, followed by polycondensation reaction. First, add all the terephthalic acid, 533g of ethylene glycol, and 0.88g of tetrabutyl titanate into the reactor with a rectification tower, and start the esterification reaction at a temperature of 250°C and a vacuum of 400mmHg, and slowly While increasing the temperature, the residual ethylene glycol was continuously added. Then move to polycondensation reaction tank, carry out polymerization reaction under vacuum condition and temperature 285 ℃.

[0090] [Manufacturing example 4]

[0091] Use antimony trioxide (0.45g) instead of tetrabutyl titanate as the reaction catalyst, and the others are the same as in Production Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile product | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com