Corrosion control system for reinforced concrete single-cylinder chimney after wet desulfurization and manufacturing method of corrosion control system

A technology for reinforced concrete and wet desulfurization, which is used in combustion methods, anti-corrosion coatings, combustion products treatment, etc. The effect of acid corrosion, corrosion prevention, and damage avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be described in detail below for further understanding of the present invention.

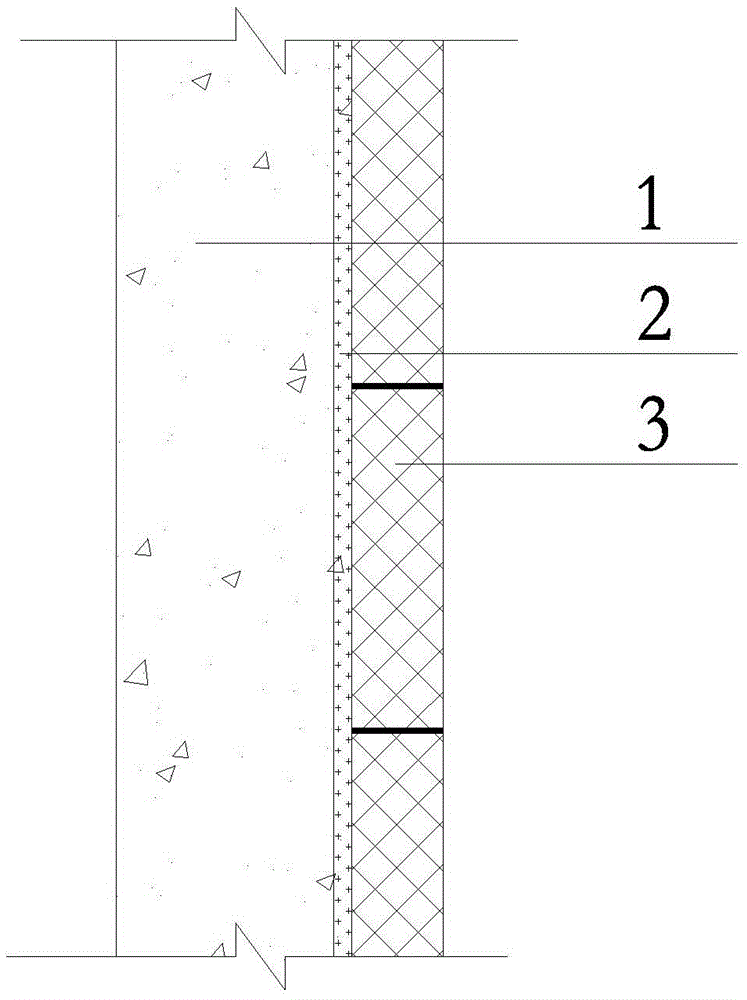

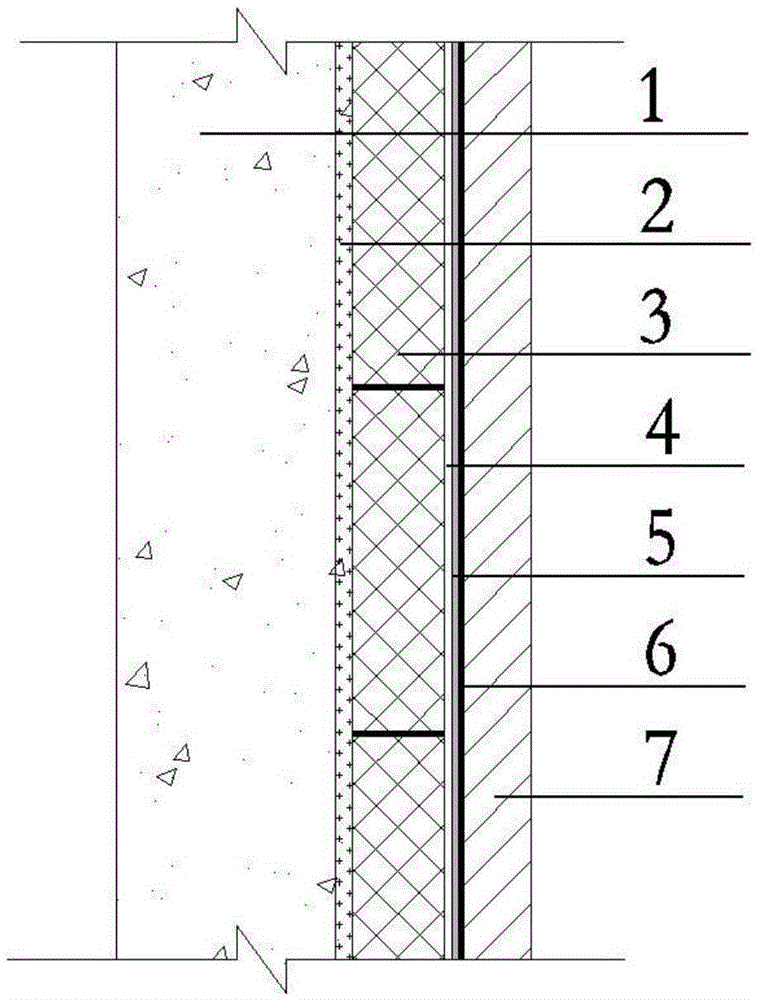

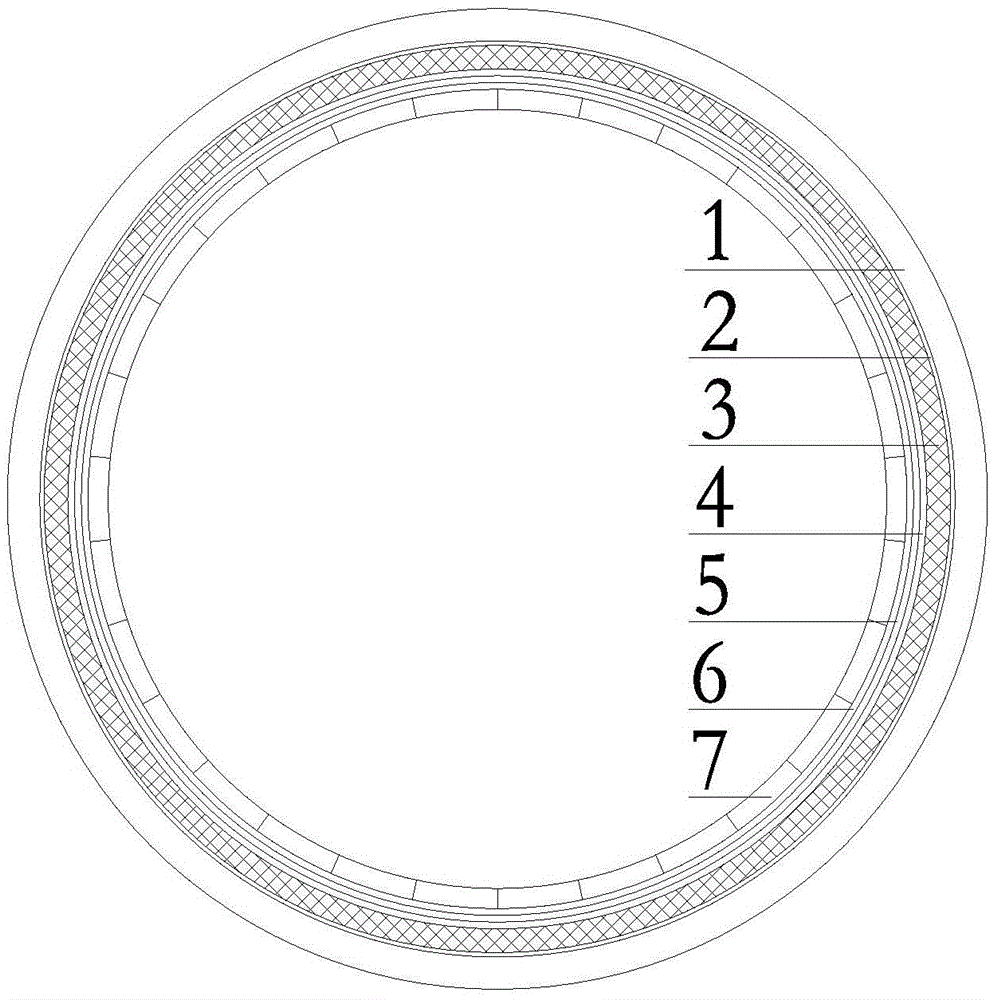

[0030] figure 1 Schematic diagram of chimney structure before anticorrosion. As shown in the figure, the chimney is generally in order from the outside to the inside: the reinforced concrete wall layer 1 of the chimney body, the thermal insulation layer 2 and the acid-resistant brick inner lining layer 3 . figure 2 It is a schematic plan view of the anticorrosion layer of the main body of the chimney of the present invention. like figure 2 As shown, the present invention is figure 1 On the basis of the chimney, a quick-drying mortar repair layer 4, a primer layer 5, an anti-corrosion adhesive layer 6 and light anti-corrosion vitrified bricks 7 are added. In detail, the chimney of the present invention is as follows from outside to inside: chimney body reinforced concrete wall layer 1, thermal insulation layer 2, acid-resistant brick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com