Enzyme carbonated beverage and preparation method thereof

A technology of carbonated drinks and enzymes, applied in the field of enzyme carbonated drinks and its preparation, can solve the problems of single taste and unhealthy taste of enzyme drinks, achieve the effects of enriching taste, suppressing obesity, and promoting gastrointestinal health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

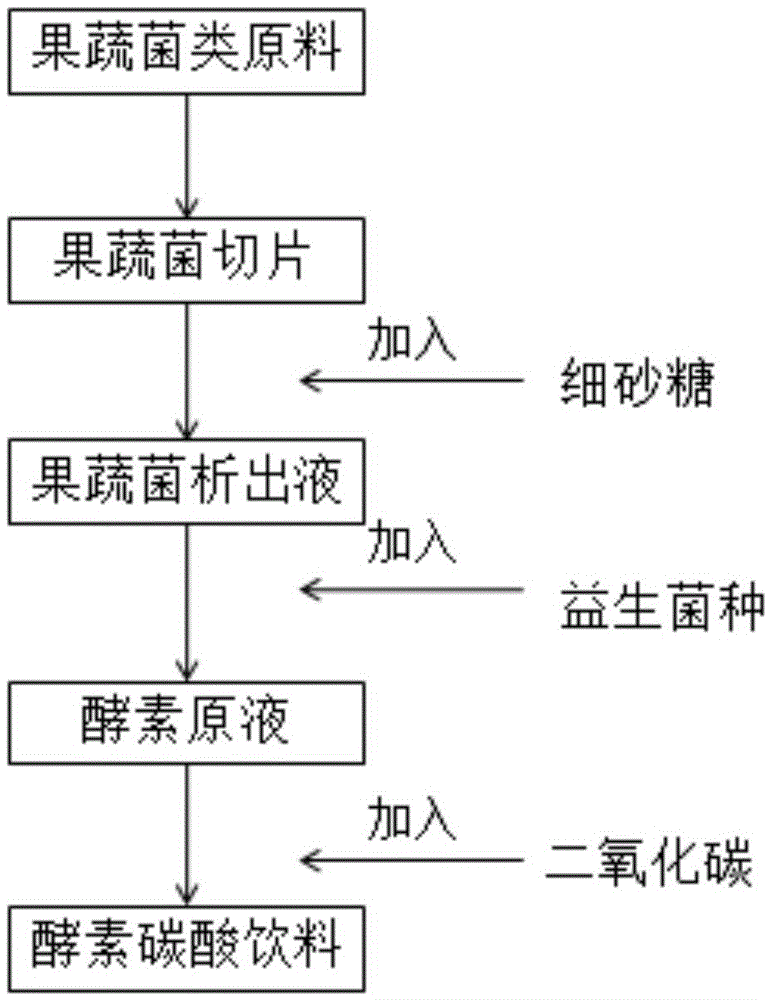

Image

Examples

Embodiment 1

[0022] Select high-quality strawberry, mulberry, kiwi fruit, grapefruit, lemon, lotus root, ginger, sweet potato, potato, red date totaling 70kg, lotus seed, hawthorn, lily, houttuynia each 10g, rinse with sterile water, peel the core, 25 Dry at ℃ and cut into slices for later use.

[0023] Cover the raw material slices with fine granulated sugar layer by layer, seal and store in a cool place for 3 months, use osmotic pressure to make the raw tissue fluid flow out, and collect the effluent. The effluent was sterilized at 121°C for 5 seconds, diluted with 25% sterile water, inoculated with 1% Lactobacillus plantarum, 2.5% Streptococcus thermophilus, and 1.5% Lactobacillus bulgaricus, mixed evenly, and fermented at 37°C. Monitor the composition of the liquid, and adjust the fermentation conditions, such as ventilation and stirring speed, to ensure that the fermentation proceeds in a beneficial direction, and stop when the pH detection value reaches 4. Filter the fermented yeast...

Embodiment 2

[0026] Select as preferred sweet potato leaves, okra, kohlrabi, rape, loofah, cauliflower, broccoli, yam, kale, and cabbage, totaling 80kg, rinse with sterile water, peel the core, dry at 25°C, and slice for later use.

[0027] Cover the raw material slices with fine granulated sugar layer by layer, seal and store in a cool place for 3 months, use osmotic pressure to make the raw tissue fluid flow out, and collect the effluent. The effluent was sterilized at 110°C for 5 seconds, diluted with 20% sterile water, inoculated with 2% Lactobacillus plantarum, 1.5% Streptococcus thermophilus, and 1.5% Lactobacillus bulgaricus, mixed evenly, and fermented at 37°C. Monitor the composition of the liquid, and adjust the fermentation conditions, such as ventilation and stirring speed, to ensure that the fermentation proceeds in a beneficial direction, and stop when the pH detection value reaches 4. Filter the fermented yeast liquid with a filter bag with a mesh size of 3000 or more. After...

Embodiment 3

[0029] Select high-quality shiitake mushrooms, straw mushrooms, enoki mushrooms, oyster mushrooms, fungus, yellow mushrooms, medlars, red dates, licorice, and burdock roots totaling 70kg, rinse them with sterile water, peel the cores, dry at 25°C, and slice them for later use.

[0030] Cover the raw material slices with fine granulated sugar layer by layer, seal and store in a cool place for 3 months, use osmotic pressure to make the raw tissue fluid flow out, and collect the effluent. The effluent was sterilized at 125°C for 3 seconds, diluted with 25% sterile water, inoculated with 1% Lactobacillus plantarum, 2.5% Streptococcus thermophilus, and 1.5% Lactobacillus bulgaricus, mixed evenly, and fermented at 37°C. Monitor the composition of the liquid, and adjust the fermentation conditions, such as ventilation and stirring speed, to ensure that the fermentation proceeds in a beneficial direction, and stop when the pH detection value reaches 4. Filter the fermented yeast liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com