Stainless steel pickling waste water/liquid waste resourceful treatment method and system

A technology for pickling wastewater and treatment methods, which is applied in water/sewage treatment, metallurgical wastewater treatment, neutralized water/sewage treatment, etc., and can solve the problem that sewage cannot fully meet the discharge standards, the reuse rate of reclaimed water cannot be guaranteed, and sludge cannot proper handling of issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

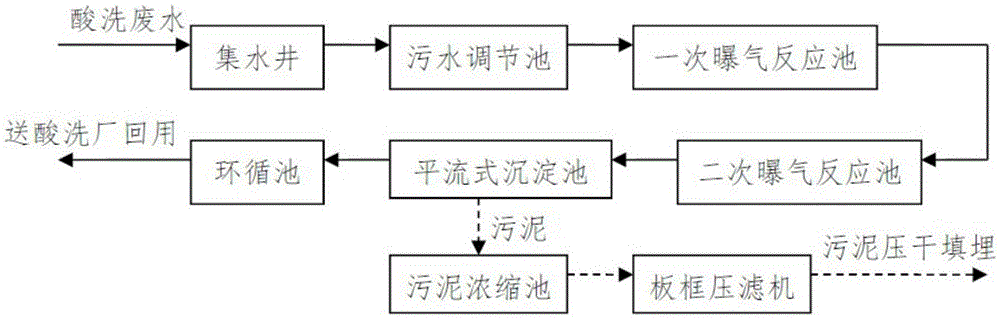

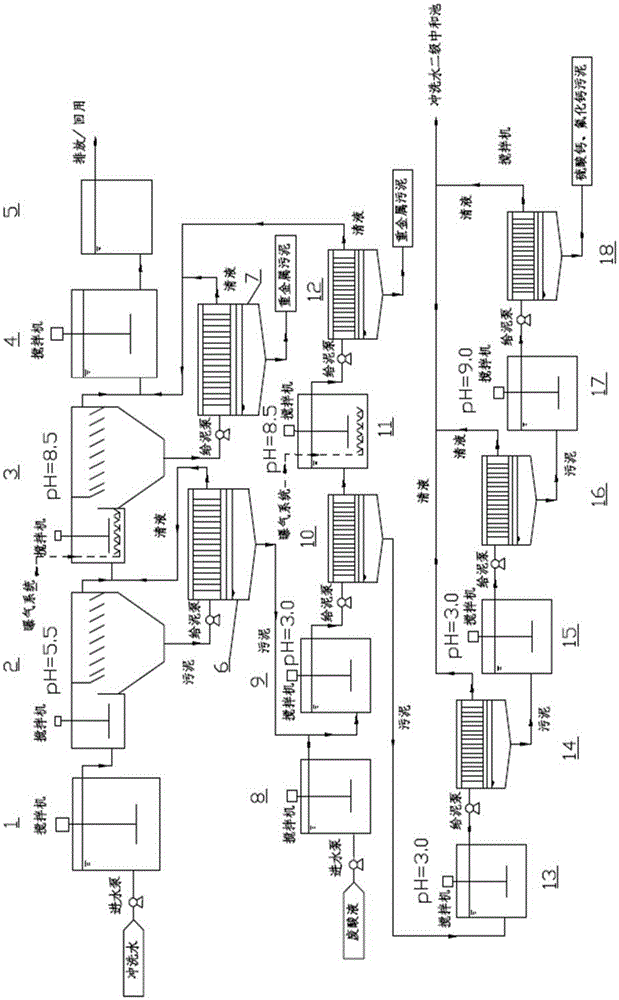

[0042] The following will combine figure 2 The stainless steel pickling wastewater / waste liquid resource treatment method and system provided by the present invention are described in detail, which is an optional embodiment of the present invention. It can be considered that those skilled in the art will not change the spirit and content of the present invention. Be able to revise and polish it.

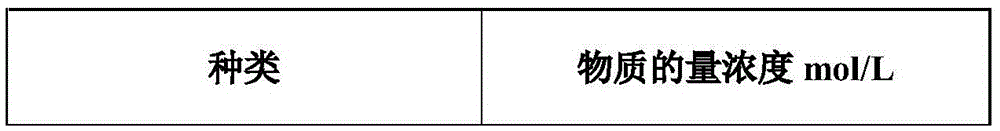

[0043] Before setting forth the design of the present invention, the following table has listed the water quality of the pickling waste acid liquor and flushing waste water of electric property:

[0044] Waste acid water quality

[0045] project

The amount of substance concentration mol / L

h 2 SO 4 Sulfate ion in the form of sulfuric acid

1.84

Fe 2+

1.07

Ni 2+

0.10

Cr 3+

0.23

mn 2+

0.11

SO 4 2- Total

3.47

[0046] PH value: less than 0.7

[0047] Washing waste water quality

[0048] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com