Preparation method of efficient and stable special foaming agent for gypsum

A foaming agent, stable technology, applied in the field of preparation of high-efficiency and stable foaming agent, can solve the problems of high foaming ratio and poor foam stability, and achieve the effect of uniform distribution of cells, enhanced strength and small diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

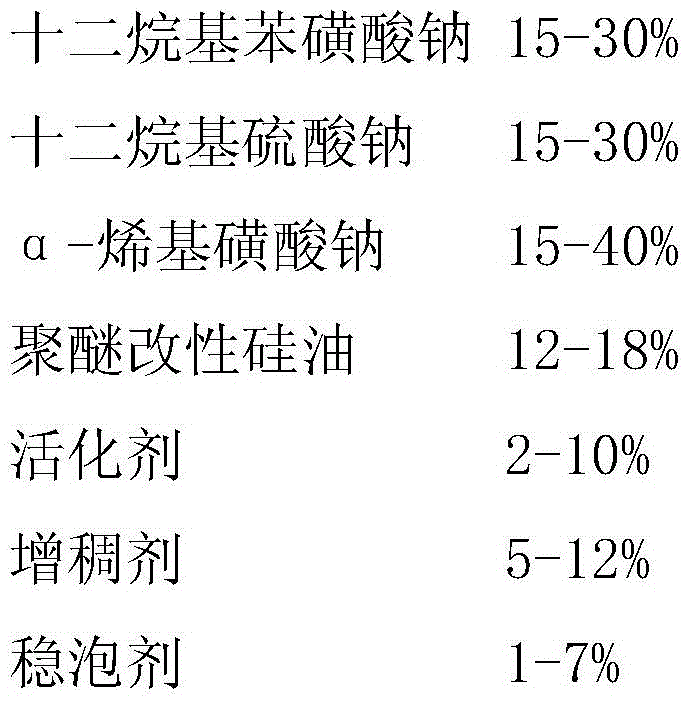

Examples

Embodiment 1

[0013]

[0014]

[0015] Mix 32.4g of sodium dodecylbenzenesulfonate, 28.8g of sodium dodecylsulfate, and 63g of sodium α-alkenylsulfonate, respectively, and use a high-pressure air foaming machine to prepare foaming mother liquor, and then add polyether Modified silicone oil 27g, urea 10.8g, thickener carboxymethyl cellulose 10.8g, foam stabilizer silicone resin polyether emulsion 7.2g, mix well.

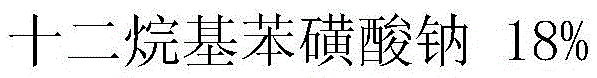

Embodiment 2

[0017]

[0018] Mix 40g of sodium dodecylbenzenesulfonate, 50g of sodium dodecylsulfate, and 75g of sodium α-alkenylsulfonate, respectively, and use a high-pressure air foaming machine to prepare foaming mother liquor, and then add polyether to modify Silicone oil 40g, urea 20g, thickener carboxymethyl cellulose 15g, foam stabilizer silicone resin polyether emulsion 10g, mix well.

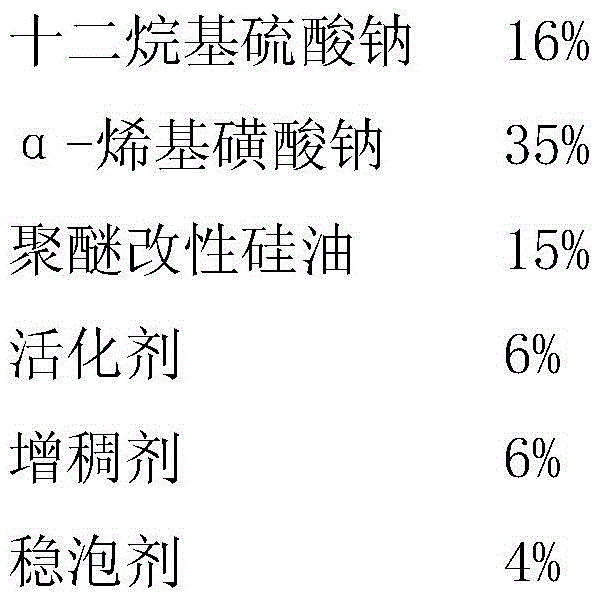

Embodiment 3

[0020]

[0021]

[0022] 75.6g of sodium dodecylbenzenesulfonate, 67.2g of sodium laurylsulfate, and 155.4g of sodium α-alkenylsulfonate were mixed respectively, and foamed by a high-pressure air foaming machine to prepare a foaming mother liquor, and then poly 58.8g of ether-modified silicone oil, 16.8g of zinc carbonate, 33.6g of thickener carboxymethyl cellulose, 12.6g of foam stabilizer silicone resin polyether emulsion, and mix well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com