Unsaturated polyether alcohol and polycarboxylate water reducer prepared by same

An unsaturated polyether alcohol technology, applied in the field of polyether synthesis, can solve the problems of complex preparation process, high energy consumption, and large pollution, and achieve the effects of mild reaction conditions, improved slump retention performance, and improved early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

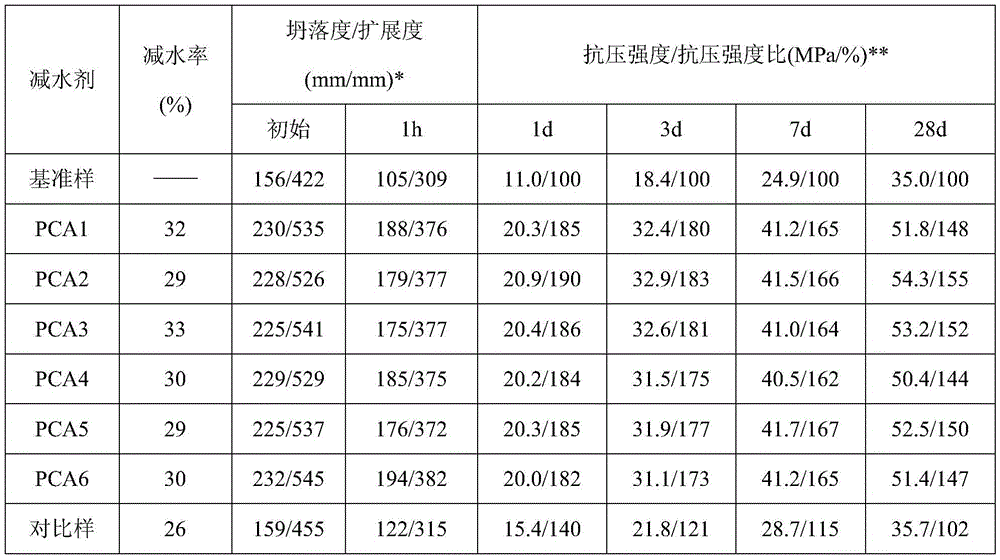

Examples

Embodiment 1

[0034] Add 116.1g of N-methallylamine to a 10L reactor, replace with nitrogen twice, raise the temperature to 70-90°C, add 118.6g of propylene oxide continuously, control the reaction pressure at 0.10-0.30MPa, and the pressure drops to Degas after 0.0Mpa; press 1.5g of catalyst B-1 into the reactor with nitrogen, raise the temperature to 105-110°C, add ethylene oxide continuously, control the reaction pressure at 0.10-0.40MPa, and add 6305.0g of epoxy in total Ethane, after the aging pressure is reduced to 0.0MPa, degassed, the temperature is lowered to 90-100°C and filtered to obtain nitrogen-containing unsaturated polyether alcohol.

[0035] Indexes: hydroxyl value: 14.0 mgKOH / g, degree of unsaturation: 0.246 mmol / g, double bond retention rate: 98.5%, molecular weight distribution coefficient D=1.03.

Embodiment 2

[0037] Add 144.2g of allylamine to the 10L reactor 1, replace with nitrogen twice, raise the temperature to 75-90°C, add 1,2-epoxybutane continuously, a total of 145.5g, control the reaction pressure at 0.1-0.2MPa, Degassing after the aging pressure drops to 0.0MPa; press 1.0g of catalyst B-1 into the reactor with nitrogen, raise the temperature to 100-110°C, add ethylene oxide continuously, control the reaction pressure at 0.10-0.30MPa, the total Add 6480.5g of ethylene oxide, after aging the pressure drops to 0.0MPa, degas, cool to 85-95°C and filter to obtain nitrogen-containing unsaturated polyether alcohol.

[0038] Indicators: hydroxyl value: 42.1 mgKOH / g, degree of unsaturation: 0.372 mmol / g, double bond retention rate: 99.5%, molecular weight distribution coefficient D=1.05.

Embodiment 3

[0040] Add 86.3g of diallylamine to the 10L reactor 1, replace with nitrogen twice, raise the temperature to 70-85°C, add propylene oxide continuously, control the reaction pressure at 0.15-0.3MPa, a total of 87.0g of propylene oxide, through Degas after the aging pressure drops to 0.0MPa; pressurize 0.43g of catalyst B-1 into the reactor with nitrogen, raise the temperature to 100-110°C, add ethylene oxide continuously, control the reaction pressure at 0.10-0.40MPa, a total of 3883.5 g ethylene oxide, after aging the pressure is reduced to 0.0MPa, degassed, cooled to 85-90°C and filtered to obtain nitrogen-containing unsaturated polyether alcohol.

[0041] Indexes: hydroxyl value: 13.1 mgKOH / g, degree of unsaturation: 0.435 mmol / g, double bond retention rate: 99.3%, molecular weight distribution coefficient D=1.02.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com