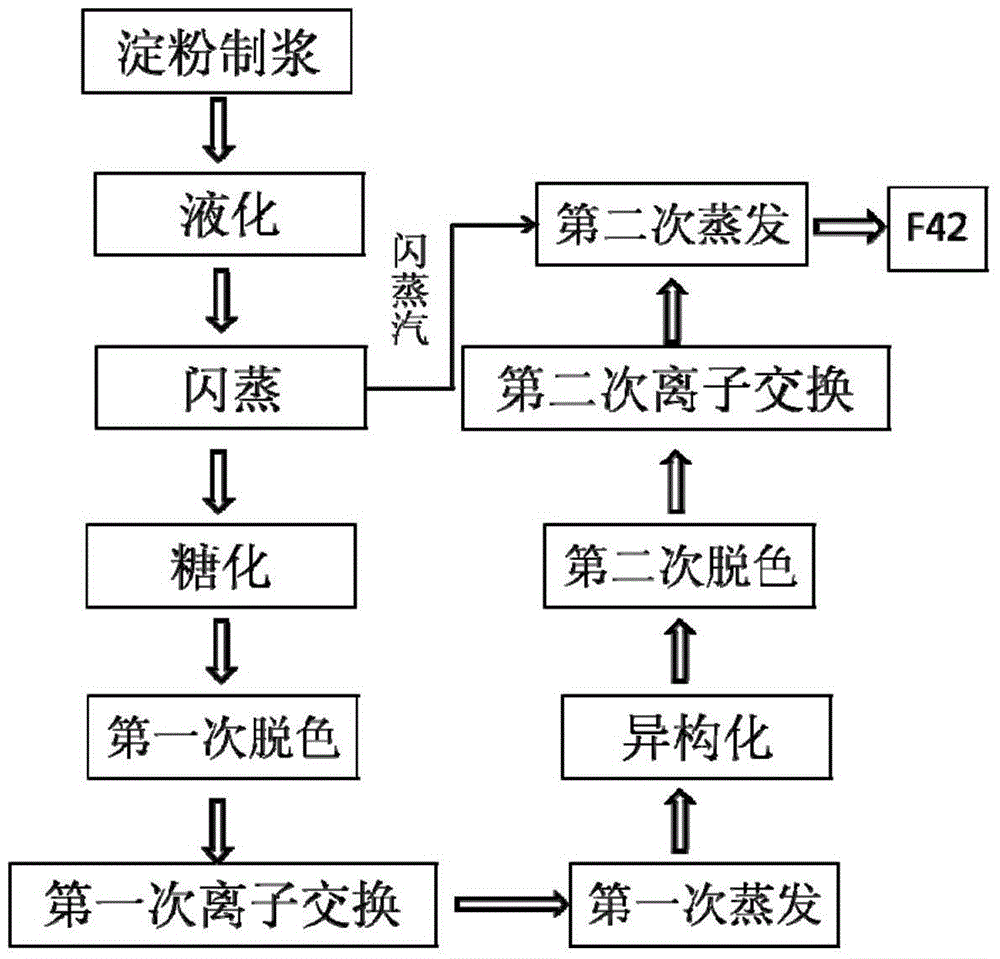

Liquidation and evaporation integrated high fructose corn syrup production method

A technology of high fructose syrup and liquefied liquid, which is applied to the production of sugar, sugar production, invert sugar production and other directions, and can solve the problems of high production cost and energy consumption, low yield of high fructose syrup, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This example is used to illustrate the preparation method of high fructose syrup provided by the present invention

[0044] (1) Starch pulping

[0045] Mixing water for pulping (a tap water desalination rate of 98%, a concentration of sodium chloride of 40 ppm, and a concentration of calcium chloride of 40 ppm) with corn starch, the amount of water used for pulping is such that the content of the prepared starch milk is 34% by weight, and The pH of the starch milk was adjusted to 5.7.

[0046] (2) Liquefaction

[0047] The starch milk obtained is mixed with 90% amylase (Novozymes or Genencor, α-amylase, in the embodiment of the present invention) with 90% of the total enzyme amount, the mixture is contacted with steam, and the mixture is contacted with steam. The condition makes the temperature of the mixture after contact with the steam be 115 ℃, and keep 6 minutes at this temperature, thereby realize high temperature jet liquefaction, wherein, with respect to every ...

Embodiment 2

[0063] This example is used to illustrate the preparation method of high fructose syrup provided by the present invention

[0064] (1) Starch pulping

[0065] Mixing water for pulping (a tap water desalination rate of 95%, a concentration of sodium chloride of 30 ppm, and a concentration of calcium chloride of 50 ppm) with corn starch, the amount of water used for pulping is such that the content of the prepared starch milk is 33% by weight, and The pH of the starch milk was adjusted to 5.5.

[0066] (2) Liquefaction

[0067] The starch milk that obtains is mixed with the amylase of total enzyme amount 88% (Novozymes company or Genenke company, alpha-amylase, all this amylase in the embodiment of the present invention), this mixture is contacted with steam, The condition of contact makes the temperature of the mixture after contact with the steam be 110 ℃, and keep 10 minutes at this temperature, thereby realize high temperature jet liquefaction; Wherein, with respect to eve...

Embodiment 3

[0075] This example is used to illustrate the preparation method of high fructose syrup provided by the present invention

[0076] (1) Starch pulping

[0077] Mixing water for pulping (a tap water desalination rate of 99%, a concentration of sodium chloride of 50 ppm, and a concentration of calcium chloride of 30 ppm) with corn starch, the amount of water used for pulping is such that the content of the prepared starch milk is 38% by weight, and The pH of the starch milk was adjusted to 5.9.

[0078] (2) Liquefaction

[0079] The starch milk that obtains is mixed with the amylase of total enzyme amount 85% (Novozymes company or Genenke company, alpha-amylase, all this amylase in the embodiment of the present invention), this mixture is contacted with steam, The condition of contact makes the temperature of the mixture after contact with the steam be 120 ℃, and keep 4 minutes at this temperature, thereby realize high temperature jet liquefaction; Wherein, with respect to ever...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com