Nozzle component, vapor deposition device and method for manufacturing organic light emitting diode device

A technology of nozzles and components, which is applied in the field of organic light-emitting diode displays, can solve the problems of difficult accurate control and low temperature, and achieve the effects of not easy to lose, improve performance, and improve equipment utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

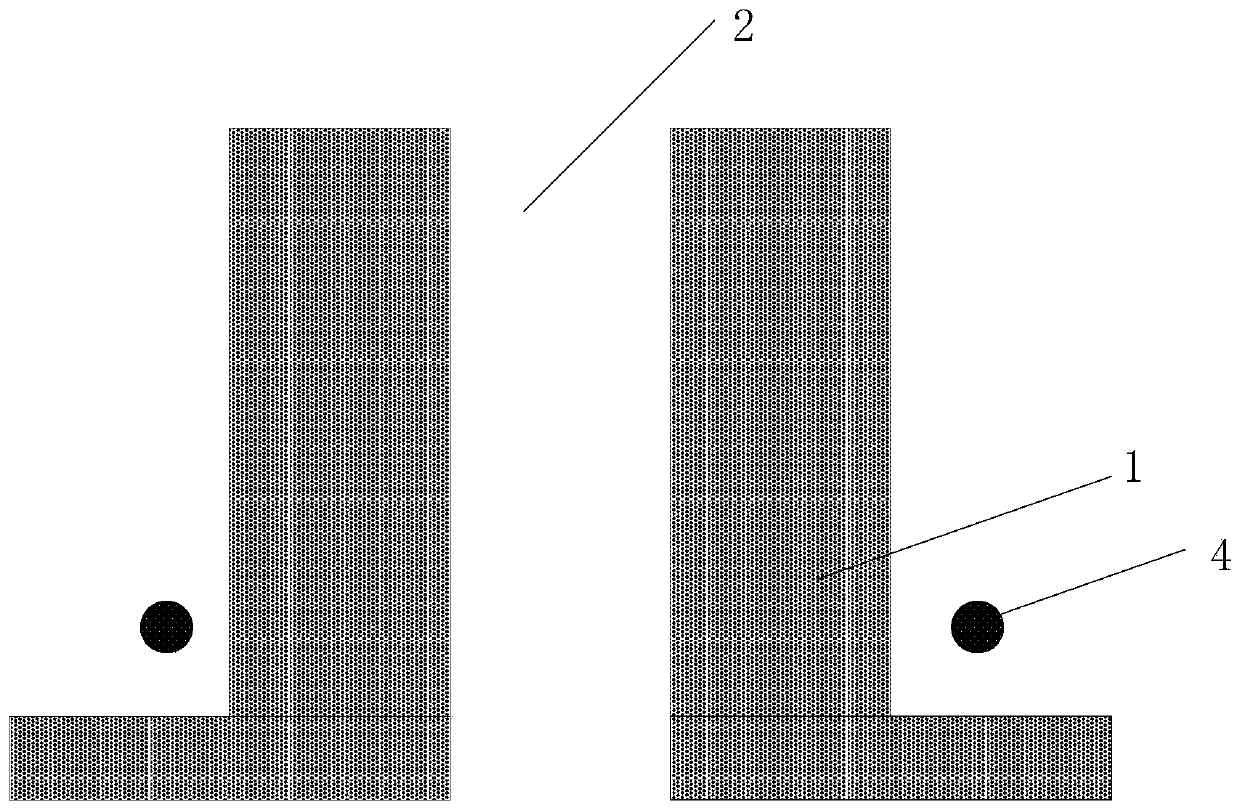

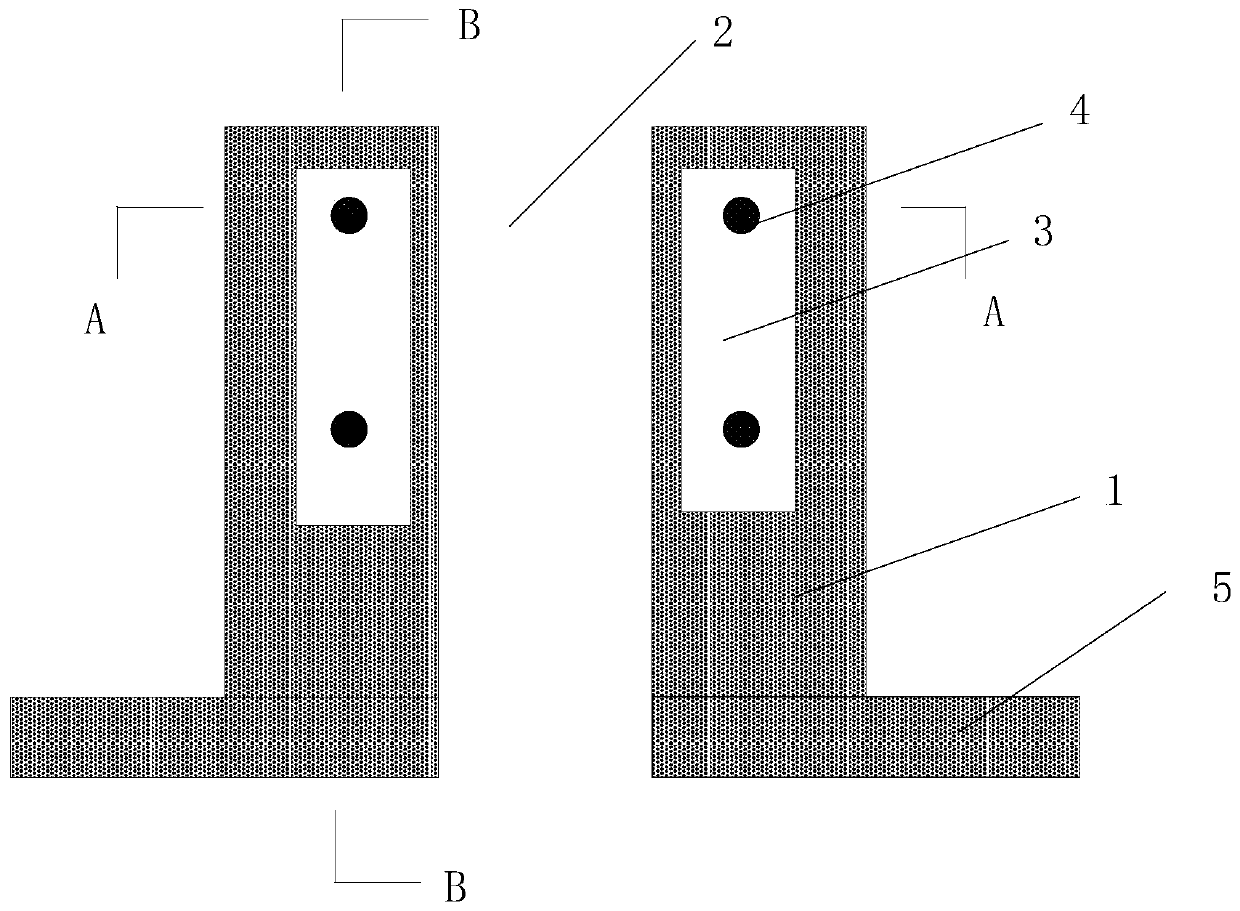

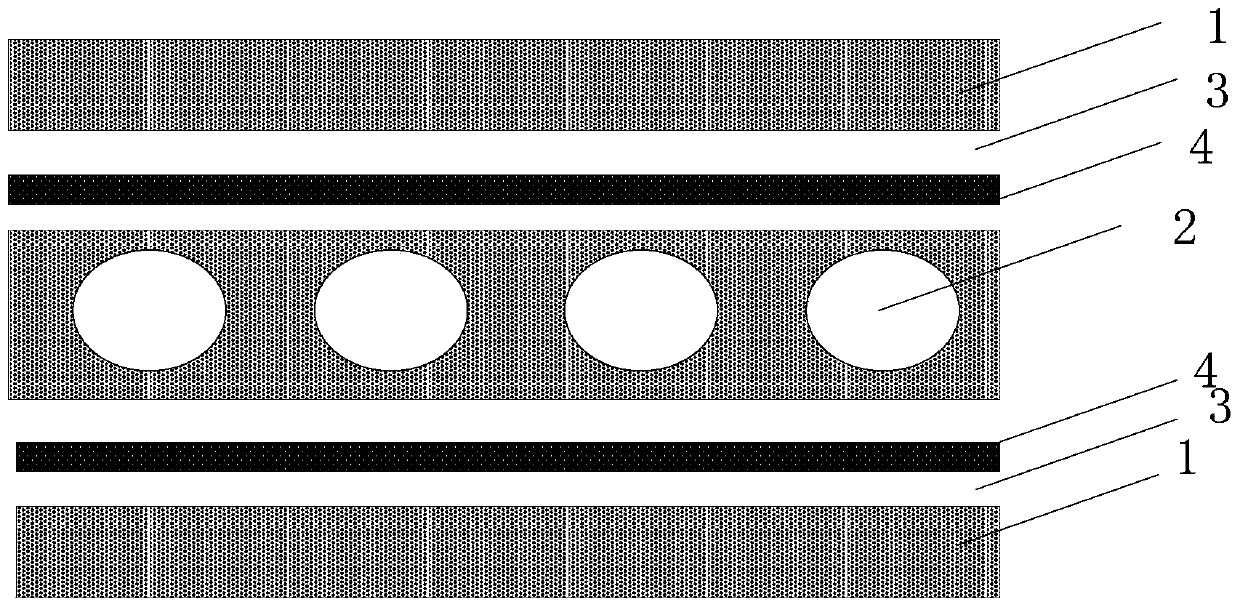

[0025] In a first embodiment of the present invention there is provided a nozzle assembly such as figure 2 , 3 , 4, including a body 1 provided with a nozzle 2, the body 1 is also provided with a hollow cavity 3 spaced apart from the nozzle 2, and a heating element 4 is disposed in the hollow cavity 3. In the present invention, the nozzle 2 is a hollow passage for ejecting evaporation materials surrounded by the materials constituting the body 1, and includes two openings, one of which is generally used to communicate with the evaporation chamber of the evaporation equipment.

[0026] Through the above scheme, since the heating element 4 is provided in the hollow c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com