A kind of neutral environment-friendly metal degreasing and descaling cleaning solution and preparation method thereof

A technology of oxide skin and cleaning fluid, which is applied in the field of metal surface cleaning to achieve the effects of low cost, simple and easy discharge, and friendly working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

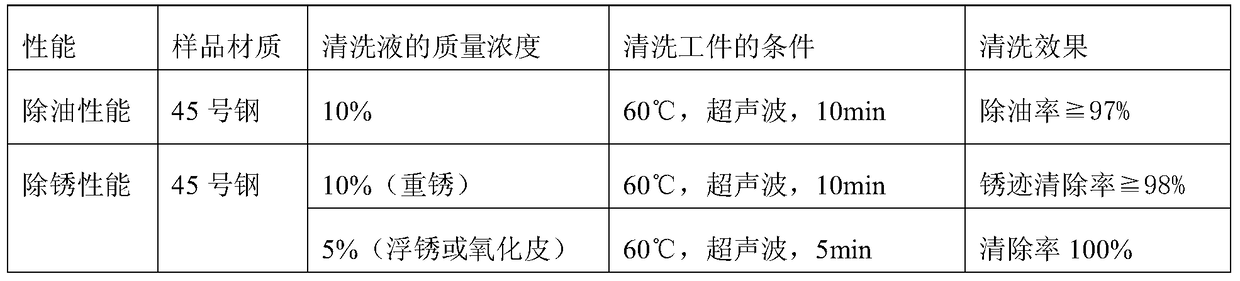

Image

Examples

Embodiment 1

[0034] A neutral environment-friendly metal degreasing and descaling cleaning solution is prepared by the following method, taking the preparation of 1000mL cleaning solution as an example:

[0035] (1) 15.0g sodium citrate is added in the container that 500mL distilled water is housed, stirs until dissolving completely, obtains sodium citrate solution;

[0036] (2) Add 10.0g of surfactant APG, 18.0g of LAS, 8.0g of FMEE, and 2.0g of penetrant JFC to the sodium citrate solution in step (1) in sequence, and stir to dissolve. Add the next ingredient;

[0037](3) After the surfactants in step (2) are all dissolved completely, add organic solvent TEA12.0g, PEG-40010.0g to the solution, stir until completely dissolved, and the solution is transparent and uniform; then add EDTA-2Na10.0g, stir until Completely dissolved to obtain a mixed solution;

[0038] (4) Dissolve 1.0g of sodium alginate in 200mL of distilled water first to obtain a sodium alginate solution; then add the solut...

Embodiment 2

[0044] A neutral environment-friendly metal degreasing and descaling cleaning solution is prepared by the following method, taking the preparation of 1000mL cleaning solution as an example:

[0045] (1) Add 10.0 g of sodium citrate and 4 g of sodium borate into a container with 500 mL of distilled water, and stir until completely dissolved to obtain a salt solution;

[0046] (2) Add 20.0g of surfactant CAB (35wt%), 20.0g of LAS, and 2.0g of penetrant JFC to the salt solution in step (1) successively, stir and dissolve, add each component after it is completely dissolved the next ingredient;

[0047] (3) After the surfactants in step (2) are completely dissolved, add organic solvent TEA15.0g, PEG-40012.0g to the solution, stir until completely dissolved, and the solution is transparent and uniform; then add EDTA-2Na8.0g, gluconic acid Sodium 10.0g, stirred until completely dissolved to obtain a mixed solution;

[0048] (4) Dissolve 1.5g of CMC in 200mL of distilled water firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com