A heating furnace with modular lining

A heating furnace and lining technology, applied in the field of heating furnaces, can solve the problems of no construction work space, loose insulation lining, difficulty in repairing damage, etc., and achieve the effects of reducing maintenance work, changing structural functions, and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

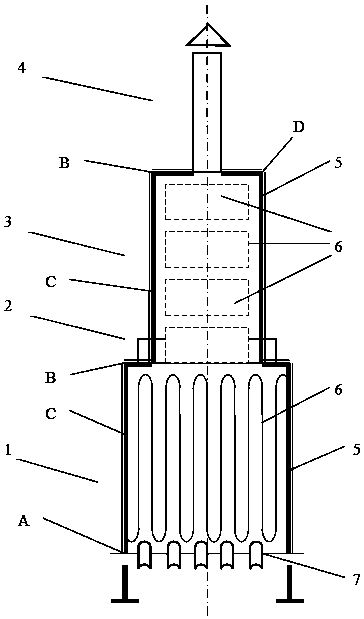

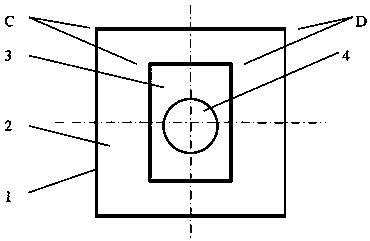

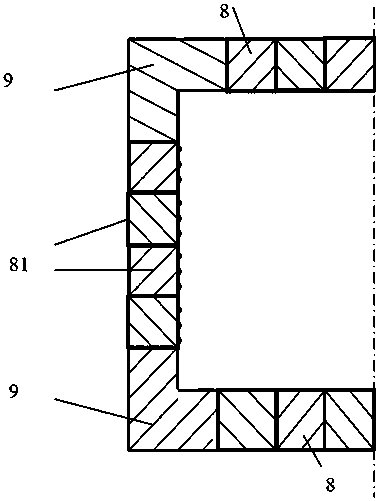

[0055] One of the specific implementations of a heating furnace with a module lining of the present application, refer to the prior art figure 1 and figure 2 As shown, including the functional structure of the heating furnace in the prior art, the structure includes a radiation section 1 at the bottom, a transition section 2 at the top of the radiation section 1, a convection section 3 at the top of the transition section 2, and a Chimney 4, the main structure of the heating furnace includes furnace wall 5, elbow box, coil pipe 6 and burner 7, and furnace wall 5 is formed by laying and welding thin steel plates on profiled steel frames. The innovations of this application are as follows: figure 1 , figure 2 , image 3 and Figure 4 As shown, a set of welding claw nails is arranged on the inner side of the furnace wall 5, and the heat insulation lining layer is poured between the welding resistance claw nails or a preformed heat insulation module lining is installed. The h...

Embodiment 2

[0059] The second specific embodiment of a heating furnace with a modular lining of the present application, the main technical solution of this embodiment is the same as that of embodiment 1, and the features not explained in this embodiment adopt the explanation in embodiment 1, in This will not be repeated here. The difference between this embodiment and Embodiment 1 is that the three-dimensional heat insulation module lining unit 10 is a three-dimensional heat insulation module lining unit 10 formed by the intersection of three planes. refer to Figure 4 As shown, the three planes are the top surface 2xoz, the right side 2yoz, and the front and back 2xoy that constitute the cavity, and the module lining has three L-shaped end surfaces, namely, the bottom end surface 1xz, the right end surface 1yz, and the front surface 1xy. When building the furnace wall 5, the three end faces are respectively spliced with other modules. Three planes form a closed cavity, which has a c...

Embodiment 3

[0062] The third specific implementation mode of changing a heating furnace with a modular lining of the present application, the main technical solution of this embodiment is the same as that of embodiment 2, and the features not explained in this embodiment adopt the explanation in embodiment 2, No further details will be given here. The difference between this embodiment and Embodiment 1 is that the three planes are quadrilateral planes. This structure is relatively easy to process, and the assembly is relatively convenient and simple.

[0063] Specifically, the three-dimensional thermal insulation module lining unit 10 is a shaped cavity module lining formed by the intersection of three rectangular planes. This kind of brick-shaped module refers to Figure 4 shown. A square is a special form of a rectangle, and all or part of the three rectangular planes may be square planes. Figure 5 The 21xoz surface shown is Figure 4 A top view of 2xoz on the middle top.

[0064]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com