Magnetic metal detection sensor

A magnetic metal and magnetoelectric sensor technology, applied in the direction of electric/magnetic exploration, instruments, measuring devices, etc., can solve the problems of high power consumption, many ancillary equipment, inconvenient operation, etc., and achieve reduced size and weight, lightweight Hand-held operation, the effect of convenient hand-held operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, further describe the present invention through embodiment, but do not limit the scope of the present invention in any way.

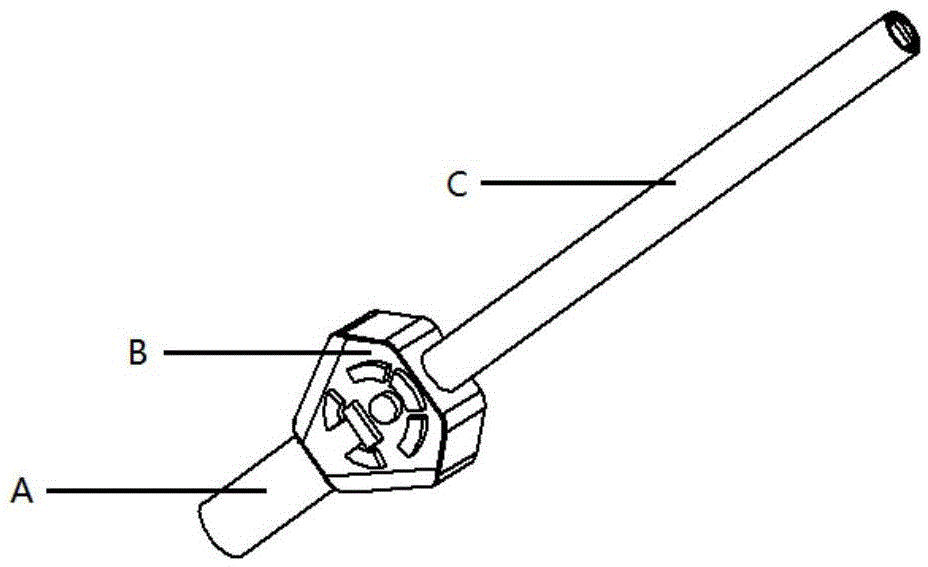

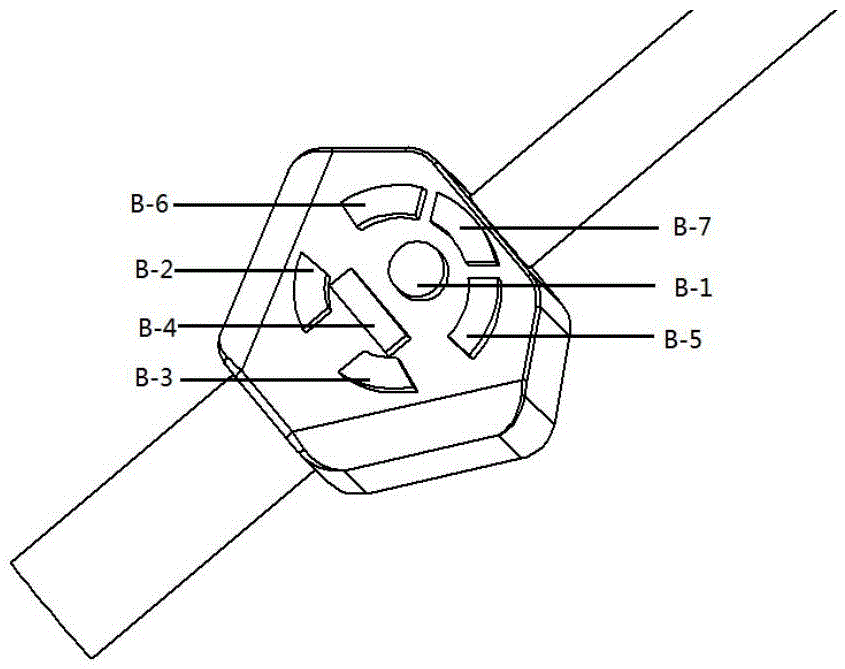

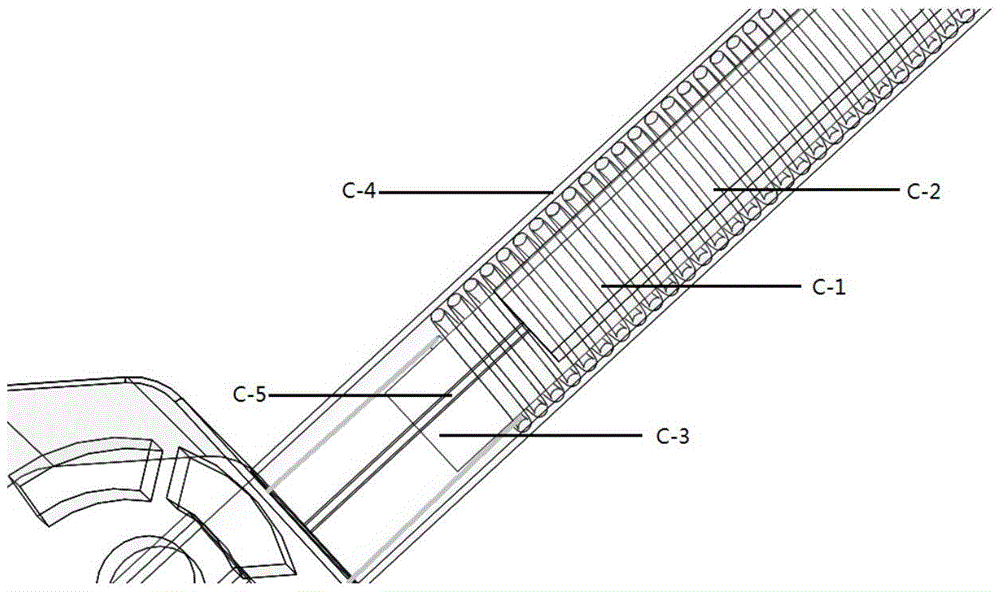

[0032]The invention provides a metal detection sensor, especially a magnetic metal detection sensor, which includes a high-sensitivity magnetoelectric sensor and a signal generating device; the signal generating device is composed of a signal generating circuit and an excitation coil; the magnetoelectric sensor is made of a magnetostrictive material Composed of piezoelectric materials, the magnetoelectric sensor has high magnetic detection sensitivity due to the piezoelectric effect of the magnetostrictive material and the piezoelectric effect of the piezoelectric material and its strong magnetoelectric coupling effect in the resonant vibration state; The excitation coil is wound around the magnetoelectric sensor, and the magnetoelectric sensor outputs a corresponding magnetoelectric coupling voltage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com