Ultrathin optical lens construction method based on artificial microstructure super surface

An artificial microstructure and optical lens technology, which is applied in optics, lenses, optical components, etc., can solve the problems of large volume of optical lenses and the inability of curved surface design to meet the integration requirements, and achieve easy integration, low loss, and high transmittance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

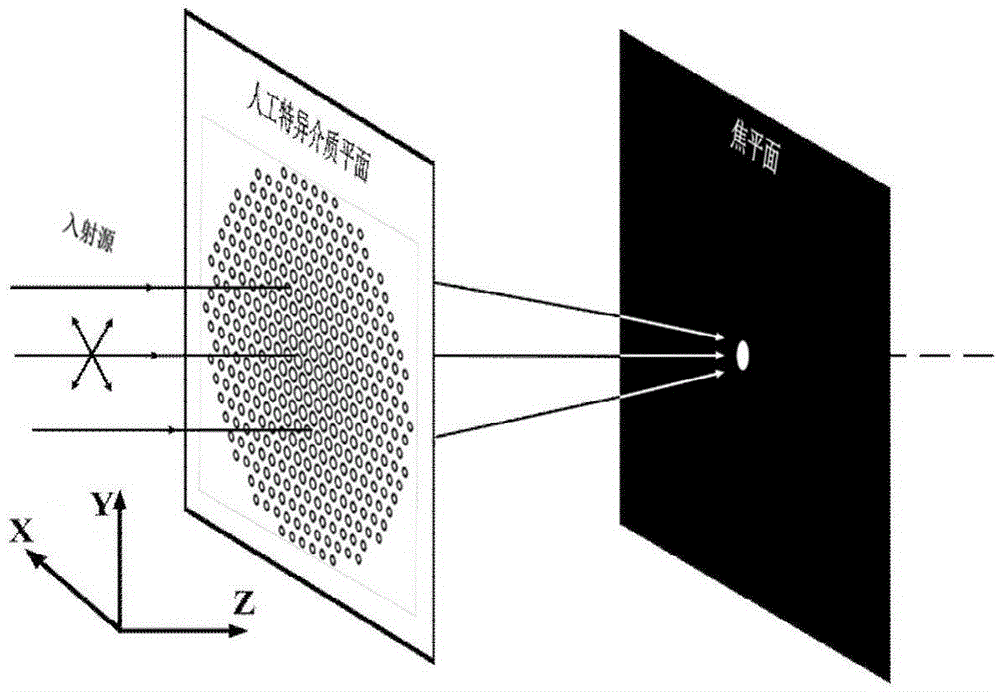

[0059] Effect of Artificial Microstructured Metasurface Constructing Ultrathin Optical Lens.

[0060] According to the above design method, an ultra-thin optical lens with an operating wavelength of 1550nm and insensitive to polarization is designed, and relevant simulation verification is carried out.

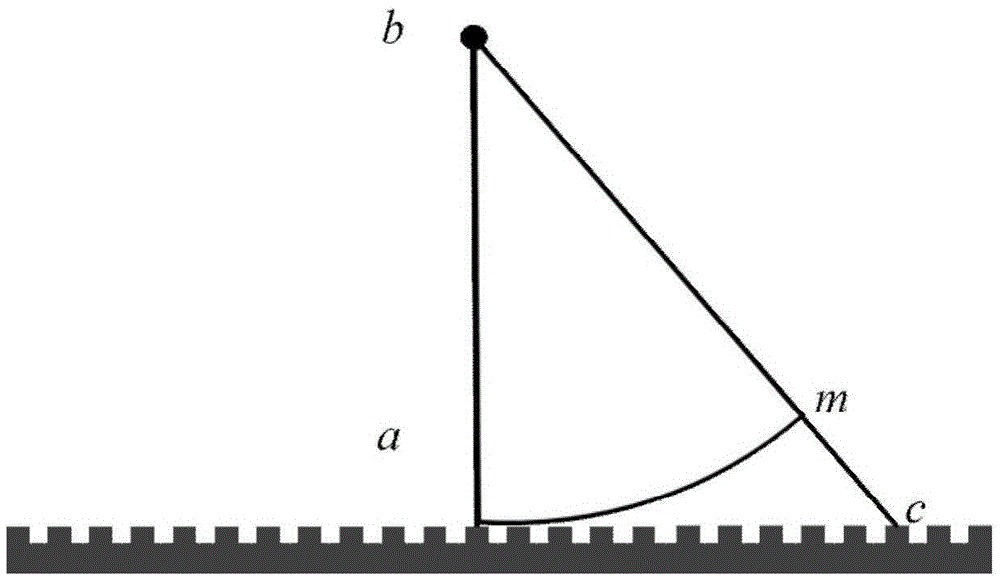

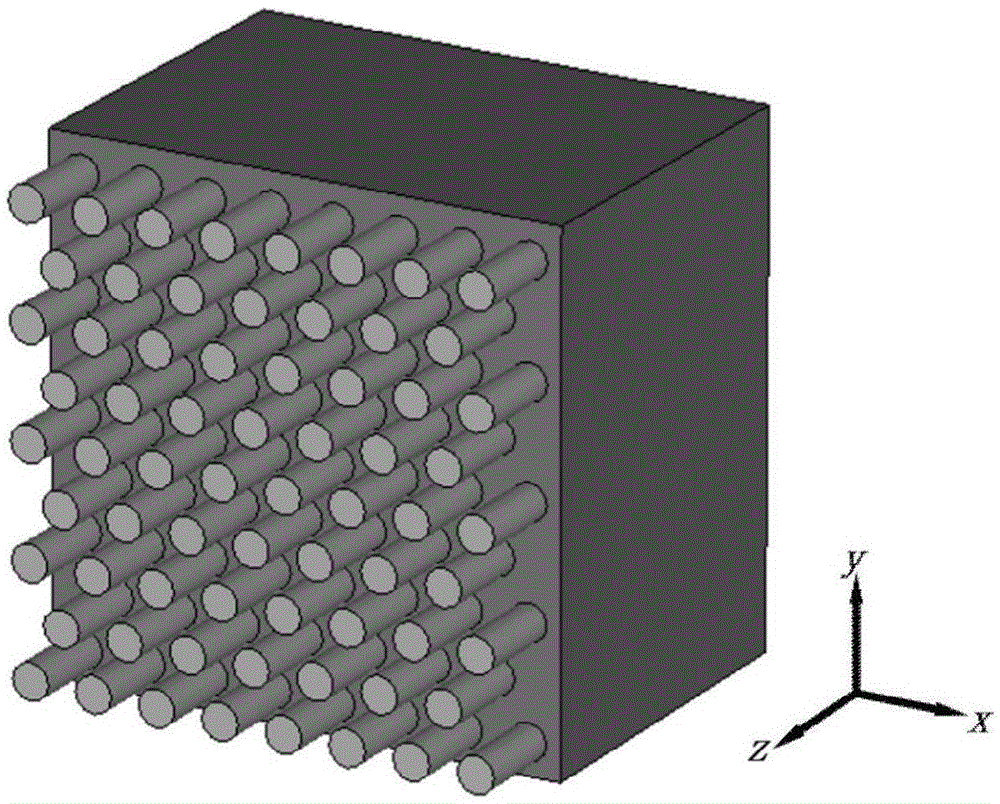

[0061] Since it is not sensitive to the polarization direction of the incident electromagnetic wave, so Figure 4 The structures designed in are all circular, that is, in Figure 3(b), for the same structural unit, its diameter 1 is equal to diameter 2. The period is 700nm and the height of the silicon cylinder is 1100nm. First calculate the phase delay of its transmission at different radii, the simulation results are as follows Figure 5 shown. It can be seen that as the radius of the silicon cylinder gradually increases from 50nm to 270nm, the phase delay (gray curve) gradually decreases with the increase of the radius, and the phase change of 2π is completed in the range...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com