A p-type silicon solar cell and its preparation method

A technology of solar cells and p-type silicon, applied in the field of solar cells, can solve the problems of low conversion efficiency, achieve the effects of improving life, increasing open circuit voltage, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, a p-type silicon solar cell.

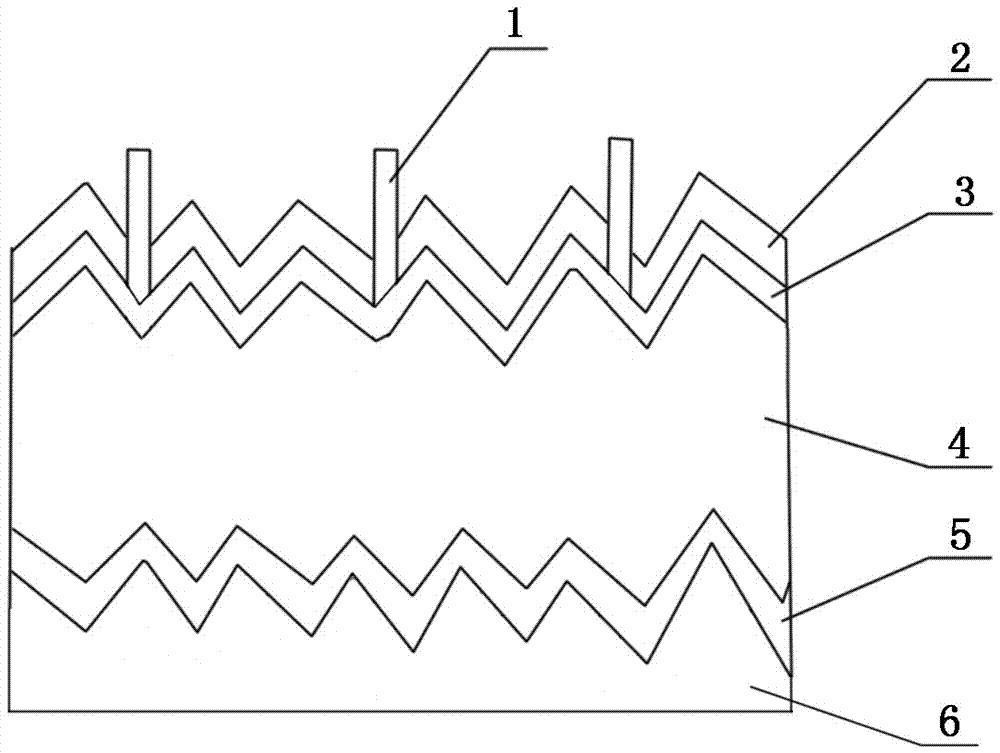

[0030] Such as figure 1As shown, the p-type silicon solar cell provided in this embodiment includes a p-type silicon substrate 4, and the p-type silicon substrate 4 may be a single crystal p-type silicon substrate or a polycrystalline p-type silicon substrate. On the front side of the p-type silicon substrate 4, n + doped layer 3, the n + An anti-reflection layer 2 is formed on the doped layer 3, and a front electrode 1 is formed on the anti-reflection layer 2 through screen printing and sintering processes. After sintering, the front electrode 1 will pass through the anti-reflection layer 2 and n + The doped layers 3 are in contact.

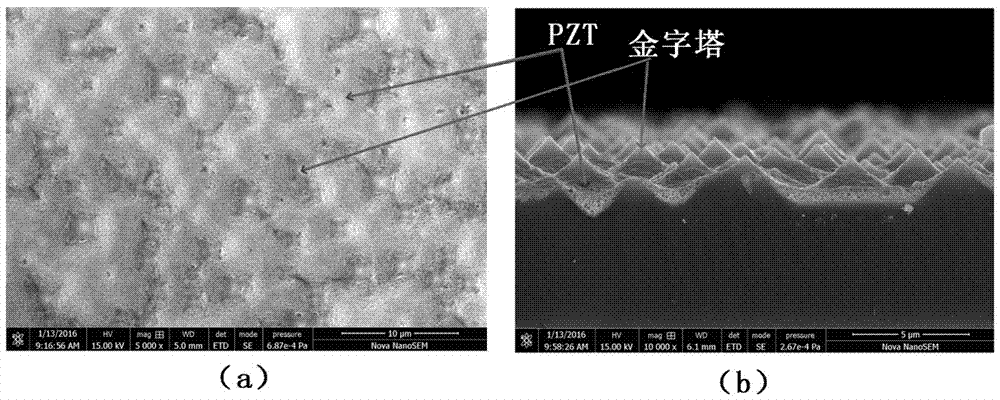

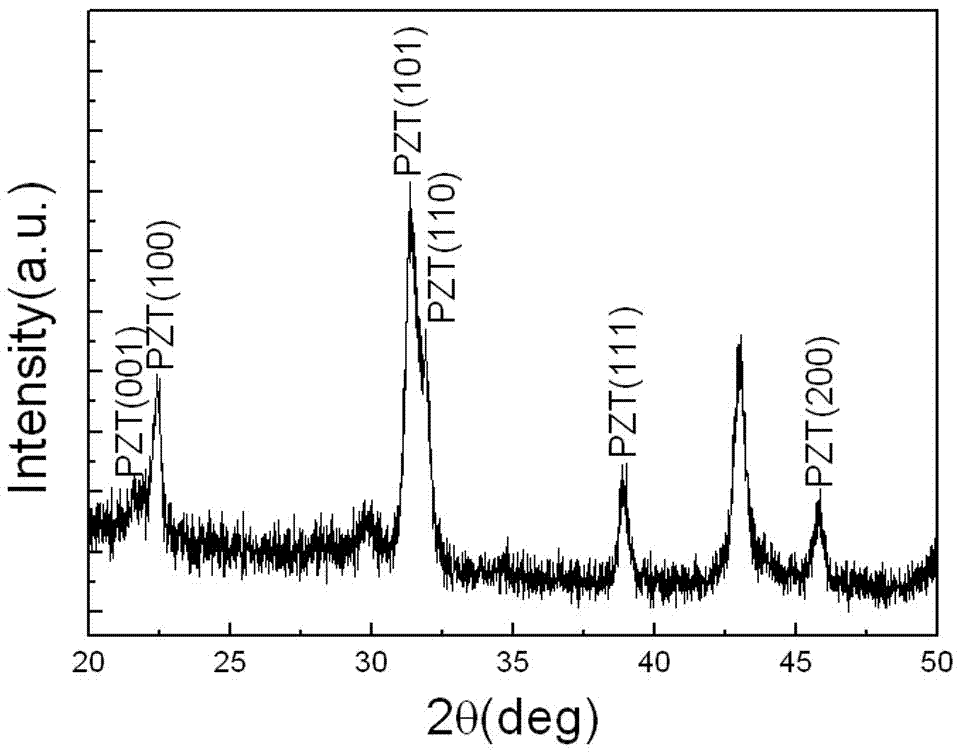

[0031] The back side passivation layer 5 is formed on the back side of the p-type silicon substrate 4, and the main material of the back side passivation layer 5 is a ferroelectric thin film material, and the ferroelectric thin film material can be, for example, lead zirconate titanate (PZT)...

Embodiment 2

[0032] Embodiment 2, a preparation method of a p-type silicon solar cell.

[0033] The preparation method of the p-type silicon solar cell provided in this embodiment includes the following steps:

[0034] ①. Select a p-type silicon substrate, and clean the selected p-type silicon substrate. After cleaning, texture the front and back of the p-type silicon substrate respectively. The p-type silicon substrate can be a single crystal p-type silicon substrate, or a polycrystalline p-type silicon substrate. When it is a single crystal p-type silicon substrate, alkali is generally used to texture it, and finally a regular pyramidal light trapping structure is formed. When it is a polycrystalline p-type silicon substrate, acid is generally used to texture it, and finally a regular uneven pit-shaped surface light-trapping structure is formed. In this embodiment, the p-type silicon substrate is a single crystal p-type silicon substrate, and the average height of the pyramids formed a...

Embodiment 3

[0055] Compared with embodiment 2, this embodiment adds a step after step ① and before step ②: planarizing the back side of the p-type silicon substrate. In this embodiment, the step of "planarizing the back of the p-type silicon substrate" is added, the purpose of which is to process the pyramid-shaped back into a slightly smooth back, that is, to smooth the top tip of the pyramid, so that the pyramid The apex-like structure of the structure and the sharp-edged horn-like structure at the bottom of the valley become smooth, and at the same time, the surface of the pyramid changes from rough to relatively smooth. After planarizing the back of the p-type silicon substrate, it should be ensured that a natural local contact can still be formed after the subsequent formation of the back passivation layer, which facilitates the subsequent preparation of the back electrode through printing and sintering processes.

[0056] In this embodiment, the back side of the p-type silicon subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com