A kind of interlayer for all-solid-state lithium-sulfur battery and all-solid-state lithium-sulfur battery

A lithium-sulfur battery, all-solid-state technology, used in lithium batteries, battery pack components, non-aqueous electrolyte batteries, etc., can solve the problems of low utilization rate of active materials, poor cycle performance, and low Coulomb efficiency, and achieve stable cycle performance. , the effect of low cost and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] An interlayer whose composition is PEO+MIL-53(Al)+LiTFSI+super P is prepared, wherein the mass percentage of super P is 7wt%.

[0032] According to the technical requirements, the metal-organic framework MIL-53(Al) was first synthesized. Weigh 1.7g of aluminum nitrate nonahydrate and 0.5g of terephthalic acid, add them to 25mL of DMF (N,N-dimethylformamide), then add 5mL of deionized water, and place the reaction kettle in an oil bath at 160°C In the process, react at a constant temperature at 400rpm for 72h, then wash with deionized water for 3 times to remove DMF, filter after washing, and dry the obtained product in a vacuum oven at 120°C for 24h to obtain MIL-53 (Al) white powder.

[0033] Film formation: Dissolve 0.1g of the prepared white powder, 0.2g of LiTFSI and 1g of PEO in 16mL of acetonitrile, stir at room temperature for 24h, evaporate the solvent at room temperature for 12h, and then dry at 80°C for 12h to obtain a thickness of 20μm polymer solid electro...

Embodiment 2

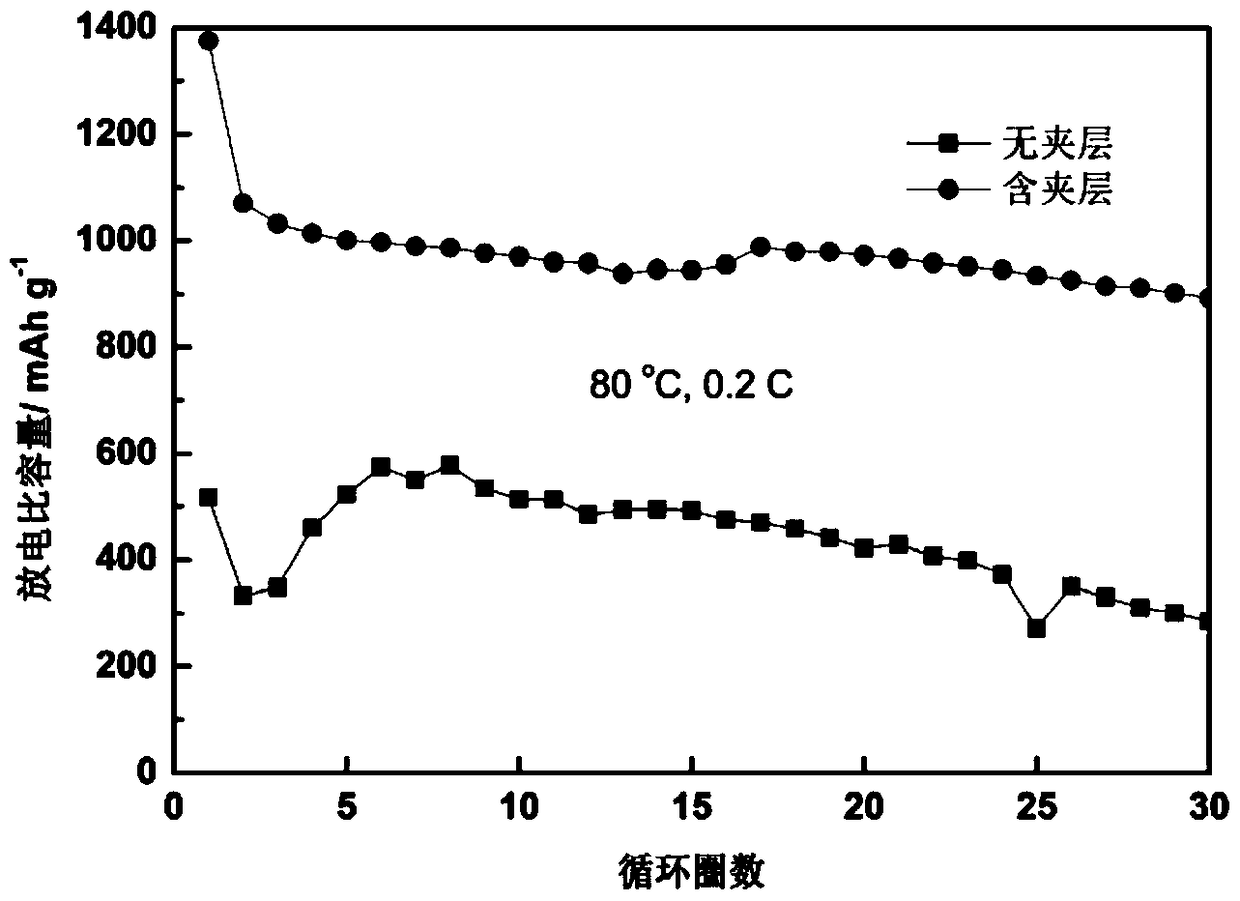

[0036] The same solid electrolyte membrane and interlayer as in Example 1 were prepared and assembled into an all-solid-state lithium-sulfur battery. The 0.1C cycle test was performed at 60°C, and the first discharge specific capacity was 1207.5mAh g -1 , there is still 912.3mAh g after 30 laps -1 capacity play.

Embodiment 3

[0038] An interlayer whose composition is PEO+MIL-53(Al)+LiTFSI+multi-walled carbon nanotubes is prepared, wherein the mass percentage of the multi-walled carbon nanotubes is 30wt%.

[0039] Film formation: prepare the same MIL-53(Al) white powder as in Example 1, dissolve 0.1g of the prepared white powder, 0.2g of LiTFSI and 1g of PEO in 16mL of acetonitrile, stir at room temperature for 24h, at room temperature The solvent was evaporated for 12 hours, and then dried at 80° C. for 12 hours to obtain a polymer solid electrolyte membrane with a thickness of 20 μm. Dissolve 0.1g of the prepared white powder, 0.2g of LiTFSI, 0.56g of multi-walled carbon nanotubes and 1g of PEO in 25mL of acetonitrile, stir at room temperature for 24h, evaporate the solvent at room temperature for 12h, and then dry at 80°C for 12h , to obtain an interlayer with a thickness of 8.5 μm.

[0040] The prepared solid electrolyte membrane and interlayer are assembled into an all-solid-state lithium-sulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com