Porous polymer film for lithium-ion battery and preparation method and application of porous polymer film

A porous film and film technology, applied in the direction of fuel cells, circuits, electrical components, etc., can solve the problems that cannot be put into large-scale production and practical application, complicated preparation process, high cost, etc., and achieve high practical value, smooth, continuous and complete surface sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

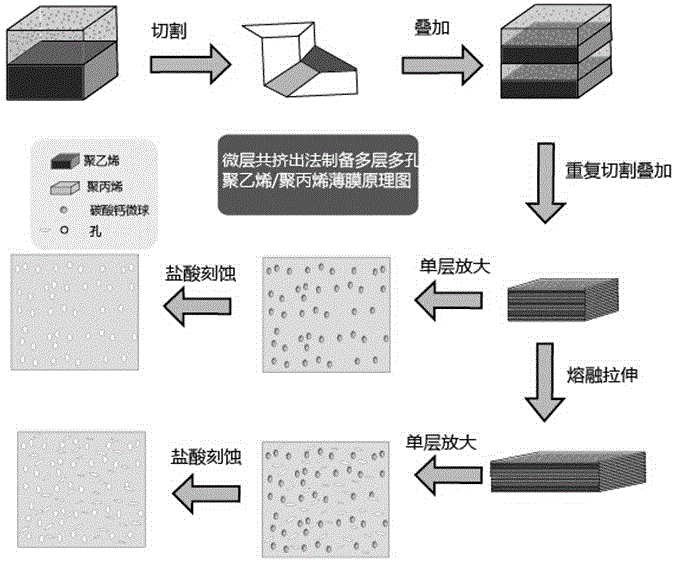

[0073] Example 1: Using submicron calcium carbonate (0.8 μm electronic grade) as a template, combined with micro-nano layer co-extrusion technology and acid etching method to prepare a porous polyethylene / polypropylene resin film with controllable pore structure and number of film layers .

[0074] The ratio of raw materials used is as follows:

[0075] 100 parts of polyethylene, by mass

[0076] 100 parts of polypropylene resin, by mass

[0077] Calcium carbonate particles (0.8μm electronic grade) 40 parts, by mass number

[0078] Dispersant-titanate coupling agent (TMC-101) 2 parts, by mass

[0079] Specific steps are as follows:

[0080] (1) Preparation of polyethylene resin / polypropylene resin (calcium carbonate) masterbatch

[0081] (1.1) Dissolve 2 parts of titanate coupling agent in ethanol solution and set aside;

[0082] (1.2) Put 40 parts of calcium carbonate particles (0.8μm electronic grade) into a high-speed mixer, heat up to 70°C, stir at a speed of 30-100r...

Embodiment 2

[0108] Example 2: Using submicron calcium carbonate (0.1 μm) as a template, a porous polyethylene / polypropylene resin film with controllable pore structure and number of film layers was prepared by combining micro-nano layer co-extrusion technology and acid etching method.

[0109] The ratio of raw materials used is as follows:

[0110] 100 parts of polyethylene, by mass

[0111] 100 parts of polypropylene resin, by mass

[0112] Calcium carbonate particles (0.1μm) 60 parts, by mass number

[0113] Dispersant-titanate coupling agent (TMC-101) 4 parts, by mass

[0114] Specific steps are as follows:

[0115] (1) Preparation of polyethylene resin / polypropylene resin (calcium carbonate) masterbatch

[0116] (1.1) Dissolve 4 parts of titanate coupling agent in ethanol solution and set aside;

[0117] (1.2) Put 60 parts of calcium carbonate particles (0.1 μm) into a high-speed mixer, heat up to 75°C, stir at a speed of 30-100rpm for 20min; put it in an oven at a constant tempe...

Embodiment 3

[0137] Example 3: Using submicron calcium carbonate (0.1 μm) as a template, combined with micro-nano layer co-extrusion technology, melt stretching method and acid etching method to prepare porous polyethylene / polyethylene with controllable pore structure and number of film layers Acrylic film.

[0138] The ratio of raw materials used is as follows:

[0139] 100 parts of polyethylene, by mass

[0140] 100 parts of polypropylene resin, by mass

[0141] Calcium carbonate particles (0.1μm) 140 parts, by mass number

[0142] Dispersant-titanate coupling agent (TMC-101) 5 parts, by mass

[0143] Specific steps are as follows:

[0144] (1) Preparation of polyethylene resin / polypropylene resin (calcium carbonate) masterbatch

[0145] (1.1) Dissolve 5 parts of titanate coupling agent in ethanol solution and set aside;

[0146] (1.2) Put 140 parts of calcium carbonate particles (0.1 μm) into a high-speed mixer, heat up to 75°C, stir at a speed of 30-100rpm for 20min; put it in an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com