Method and device for purifying silicon tetrachloride of optical fiber grade through total reflux distillation

A silicon tetrachloride, total reflux technology, applied in the direction of halogenated silicon compounds, halogenated silanes, etc., can solve the problems of high equipment cost and energy consumption, insufficient impurity removal ability, and few types of impurity removal, etc., to reduce production costs, Easy to separate and meet process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

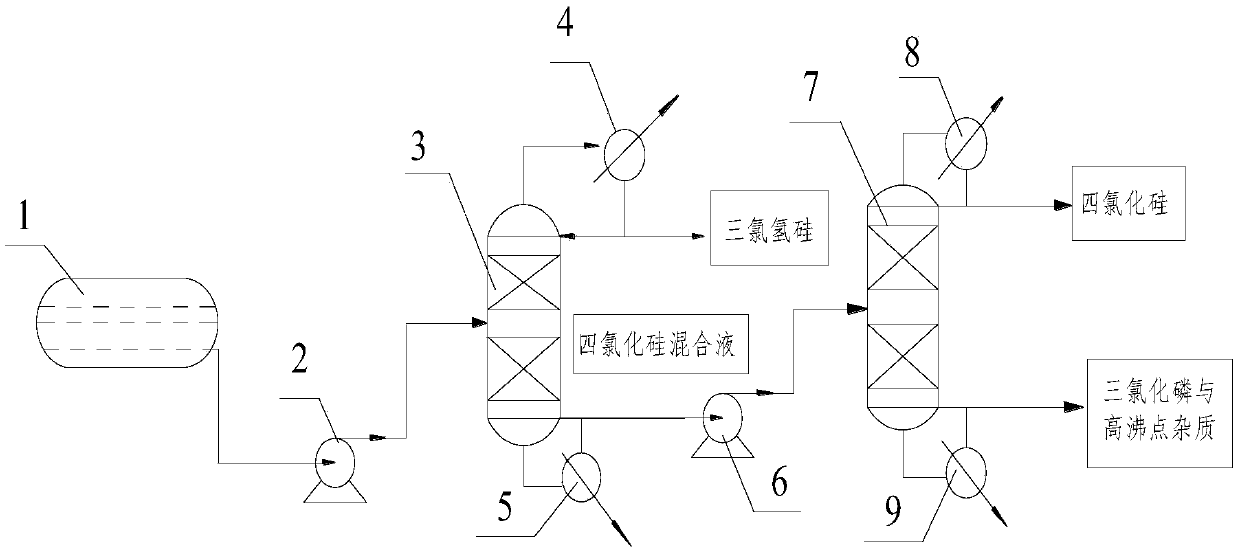

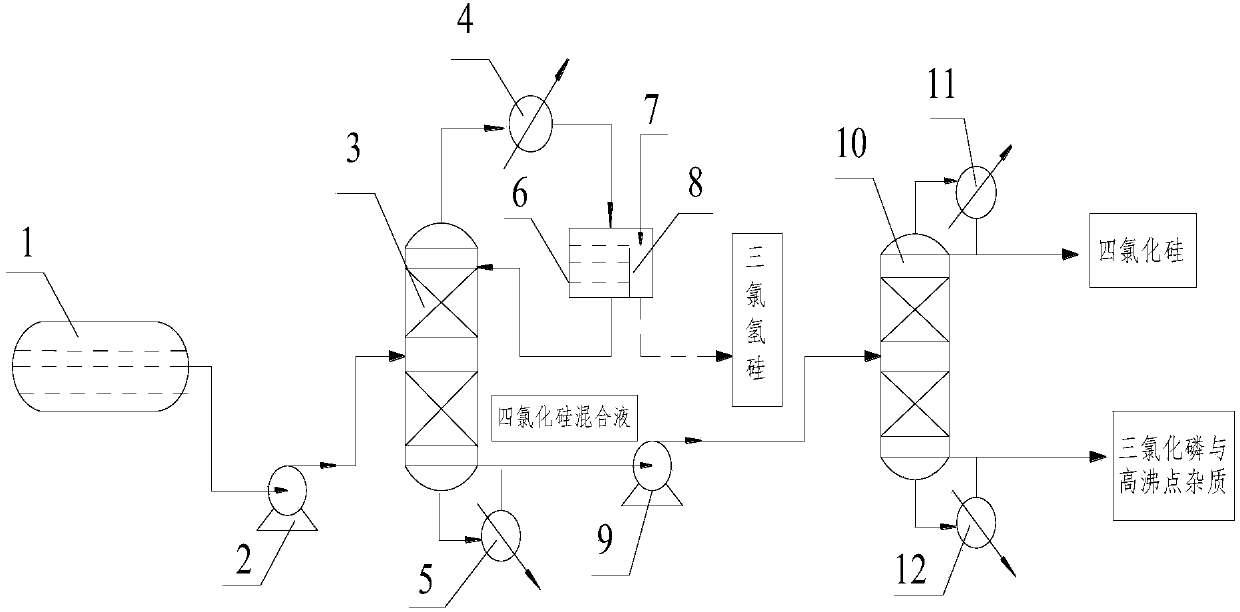

[0030](a) The silicon tetrachloride waste liquid preheated to 40°C enters the tower from the upper part of the light removal rectification tower. The number of trays in the light removal rectification tower is 40, and the feeding position is the 15th from top to bottom. block, the flow rate of the raw material liquid is: 1150kg / h, and the components of the raw material liquid are: 90% silicon tetrachloride; 9% trichlorosilane and 1% phosphorus trichloride, etc. The overhead steam of the light removal rectification tower 3 is condensed by the condenser 4 and continuously accumulated in the reflux tank 6. Maintaining the total reflux operation makes the light components continuously concentrated in the tower top. When the liquid in the reflux tank exceeds the operating liquid level (According to the actual operation situation, 70%), the liquid in the reflux tank beyond the overflow plate flows into the extraction area and is extracted; the operating pressure at the top of the tow...

Embodiment 2

[0033] (a) The silicon tetrachloride waste liquid preheated to 43°C enters the tower from the upper part of the silicon tetrachloride rectification tower. On the 16th board, the flow rate of the raw material liquid is: 1500kg / h, and the components of the raw material liquid are: 91.57% silicon tetrachloride; 8.4% trichlorosilane and 0.03% phosphorus trichloride, etc. The overhead steam of the light removal rectification tower 3 is condensed by the condenser 4 and continuously accumulated in the reflux tank 6. Maintaining the total reflux operation makes the light components continuously concentrated in the reflux tank. When the liquid in the reflux tank exceeds the operating liquid level (According to the actual operation situation, 70%), the liquid beyond the overflow plate in the reflux tank flows into the production area and then is produced; the operating pressure at the top of the tower is 210kPa, and the operating pressure at the bottom of the tower is 212.8kPa; the opera...

Embodiment 3

[0036] (a) The silicon tetrachloride waste liquid preheated to 45°C enters the tower from the upper part of the silicon tetrachloride rectification tower. For the 20th plate, the flow rate of the raw material liquid is 2000kg / h, and the components of the raw material liquid are: 92% silicon tetrachloride; 7% trichlorosilane and 1% phosphorus trichloride, etc. The overhead steam of the light removal rectification tower 3 is condensed by the condenser 4 and continuously accumulated in the reflux tank 6. Maintaining the total reflux operation makes the light components continuously concentrated in the reflux tank. When the liquid in the reflux tank exceeds the operating liquid level (According to the actual operation situation, 70%), the liquid in the reflux tank beyond the overflow plate flows into the extraction area and is extracted; the operating pressure at the top of the tower is 250kPa, and the operating pressure at the bottom of the tower is 260kPa; the operating temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com