A flexible waterproof adhesive coating for stone

A flexible waterproof and self-adhesive coating technology, used in the field of stone backing, can solve the problems of poor compatibility between Tg emulsion and cement, and achieve the effects of good water retention, improved stability and reduced water-cement ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

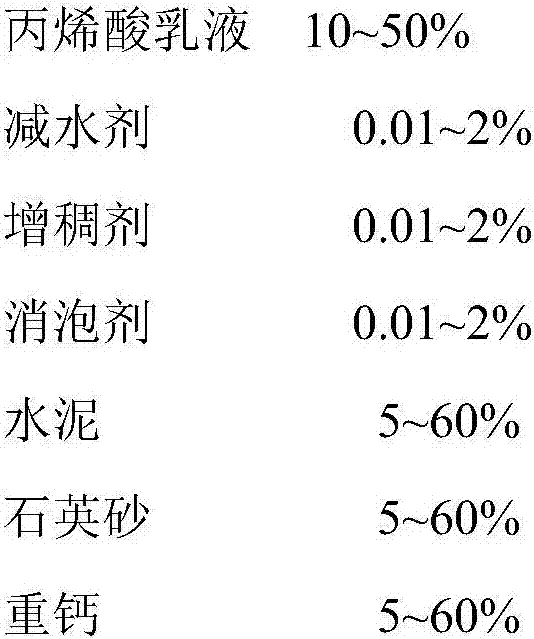

Method used

Image

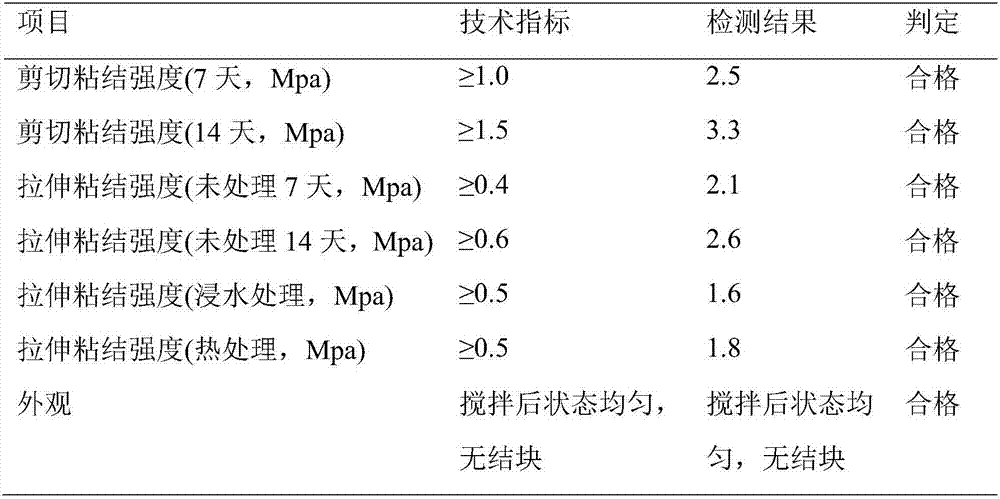

Examples

Embodiment 1

[0021] According to mass percentage, take 25% of acrylic emulsion, 0.2% of water reducer, 0.1% of thickener, and 0.1% of defoamer and mix them evenly into a liquid; then select 25% of cement, 15% of 70-140 mesh quartz sand, 120- 15% of 180 quartz sand and 19.6% of 325 heavy calcium are mixed evenly to form a powder, and the prepared liquid and powder are evenly mixed to obtain the flexible waterproof adhesive coating for stone.

[0022] Among them, in the acrylic emulsion, styrene accounts for 20% of the total mass of the five monomers, methyl methacrylate accounts for 10% of the total mass of the five monomers, methacrylic acid accounts for 3% of the total mass of the five monomers, and isooctyl acrylate accounts for 65% of the total mass of the five monomers, and silicone accounts for 2% of the total mass of the five monomers; the acrylic emulsion is prepared according to the preparation method disclosed in Chinese patent 201110450289.3.

Embodiment 2

[0024] According to mass percentage, take 35% of acrylic emulsion, 0.1% of water reducer, 0.1% of thickener, and 0.1% of defoamer to mix evenly into a liquid; then select 25% of cement, 5% of 70-140 mesh quartz sand, 120- 15% of 180% quartz sand and 19.7% of 500% heavy calcium are uniformly mixed to form a powder, and the prepared liquid and powder are evenly mixed to obtain the flexible waterproof adhesive coating for stone materials.

[0025] Among them, in the acrylic emulsion, styrene accounts for 70% of the total mass of the five monomers, methyl methacrylate accounts for 2% of the total mass of the five monomers, methacrylic acid accounts for 5% of the total mass of the five monomers, and isooctyl acrylate accounts for 21% of the total mass of the five monomers, and silicone accounts for 2% of the total mass of the five monomers; the acrylic emulsion is prepared according to the preparation method disclosed in Chinese patent 201110450289.3.

Embodiment 3

[0027] According to mass percentage, take 30% of acrylic emulsion, 0.1% of water reducer, 0.2% of thickener, and 0.1% of defoamer to mix evenly into a liquid; then select 20% of cement, 5% of 70-140 mesh quartz sand, 120- 25% of 180 quartz sand and 19.6% of 325 heavy calcium are uniformly mixed to form a powder, and the prepared liquid and powder are uniformly mixed to obtain the flexible waterproof adhesive coating for stone.

[0028] Among them, in the acrylic emulsion, styrene accounts for 27% of the total mass of the pentamonomer, methyl methacrylate accounts for 1% of the total mass of the pentamonomer, methacrylic acid accounts for 1% of the total mass of the pentamonomer, and isooctyl acrylate accounts for 1% of the total mass of the pentamonomer. 70% of the total mass of the five monomers, and silicone accounts for 1% of the total mass of the five monomers; the acrylic emulsion is prepared according to the preparation method disclosed in Chinese patent 201110450289.3. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com