Nanometer flaky 1,1-diamido-2,2-binitro ethylene explosive and preparation method thereof

A technology of dinitroethylene explosive and dinitroethylene, which is applied in explosives processing equipment, explosives, nanotechnology and other directions, can solve the problems of high cost, difficult methods, complicated technological process, etc., and achieves short preparation period and solvent recycling. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] First, at room temperature, weigh 0.1 g of 1,1-diamino-2,2-dinitroethylene and 0.1 g of polyvinylpyrrolidone, add 80 g of ethanol, heat to 65°C, and stir at 450 rpm to completely dissolve them into clear solution;

[0032] Then, the obtained solution was continuously stirred and refluxed at 65°C for 60min;

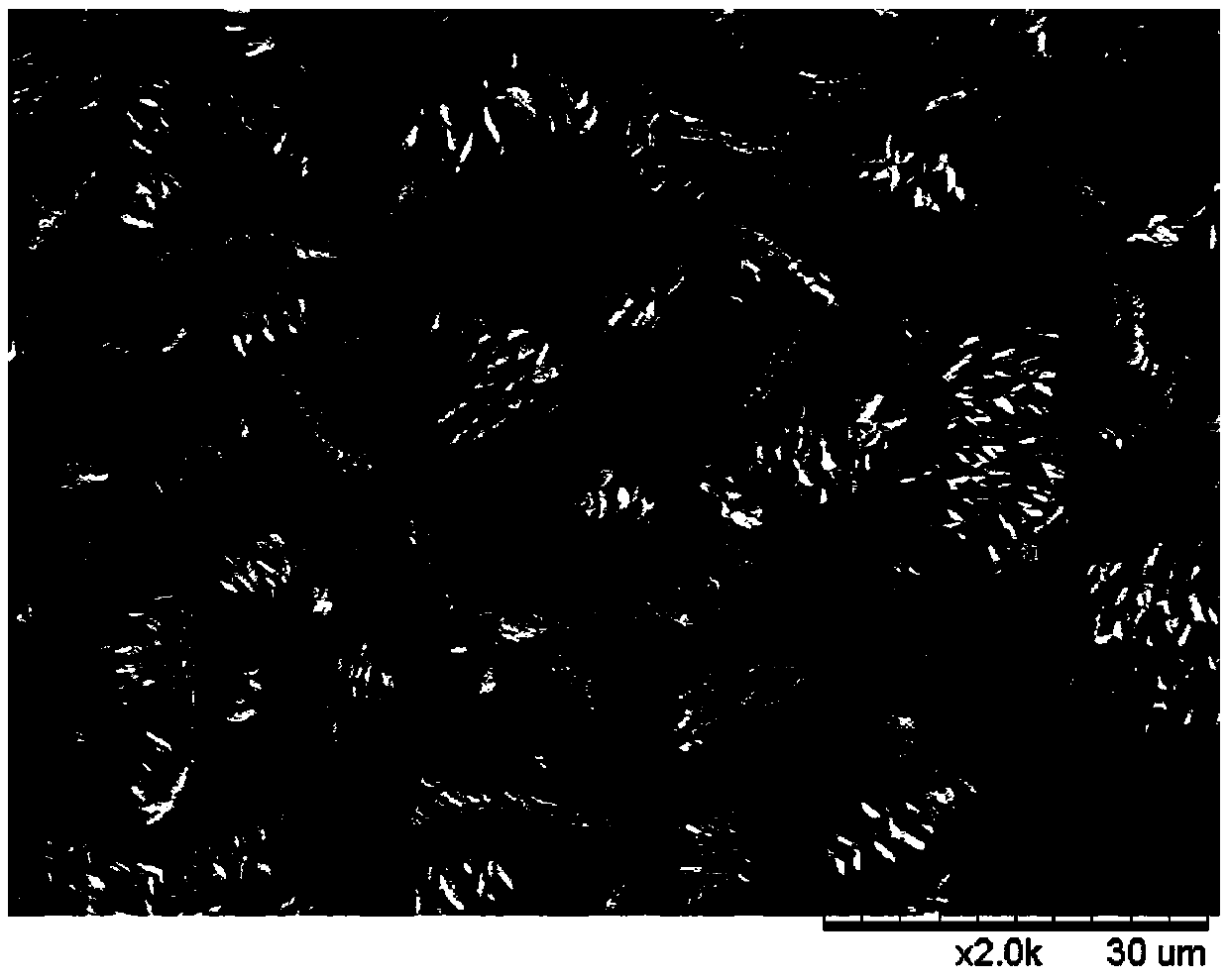

[0033] Finally, the solution was cooled to 0°C according to the cooling rate of 2°C / min until the crystals of the explosives were completely precipitated; filtered, washed with deionized water to remove the surfactant, and dried to obtain the following figure 1 and figure 2 The nanoplatelet 1,1-diamino-2,2-dinitroethylene explosive shown.

[0034] The nanosheet 1,1-diamino-2,2-dinitroethylene explosive has a sheet diameter of about 1 μm, a thickness of about 100 nm, and a product purity of 99.2 percent.

Embodiment 2

[0036] First, 1.0 g of 1,1-diamino-2,2-dinitroethylene and 0.5 g of polyethylene glycol cetyl ether were weighed at room temperature, 100 g of N-methylpyrrolidone was added, heated to 60°C, and stirred. The speed is 800rpm, so that it completely dissolves into a clear solution;

[0037] Then, the obtained solution was continuously stirred and refluxed at 60°C for 120min;

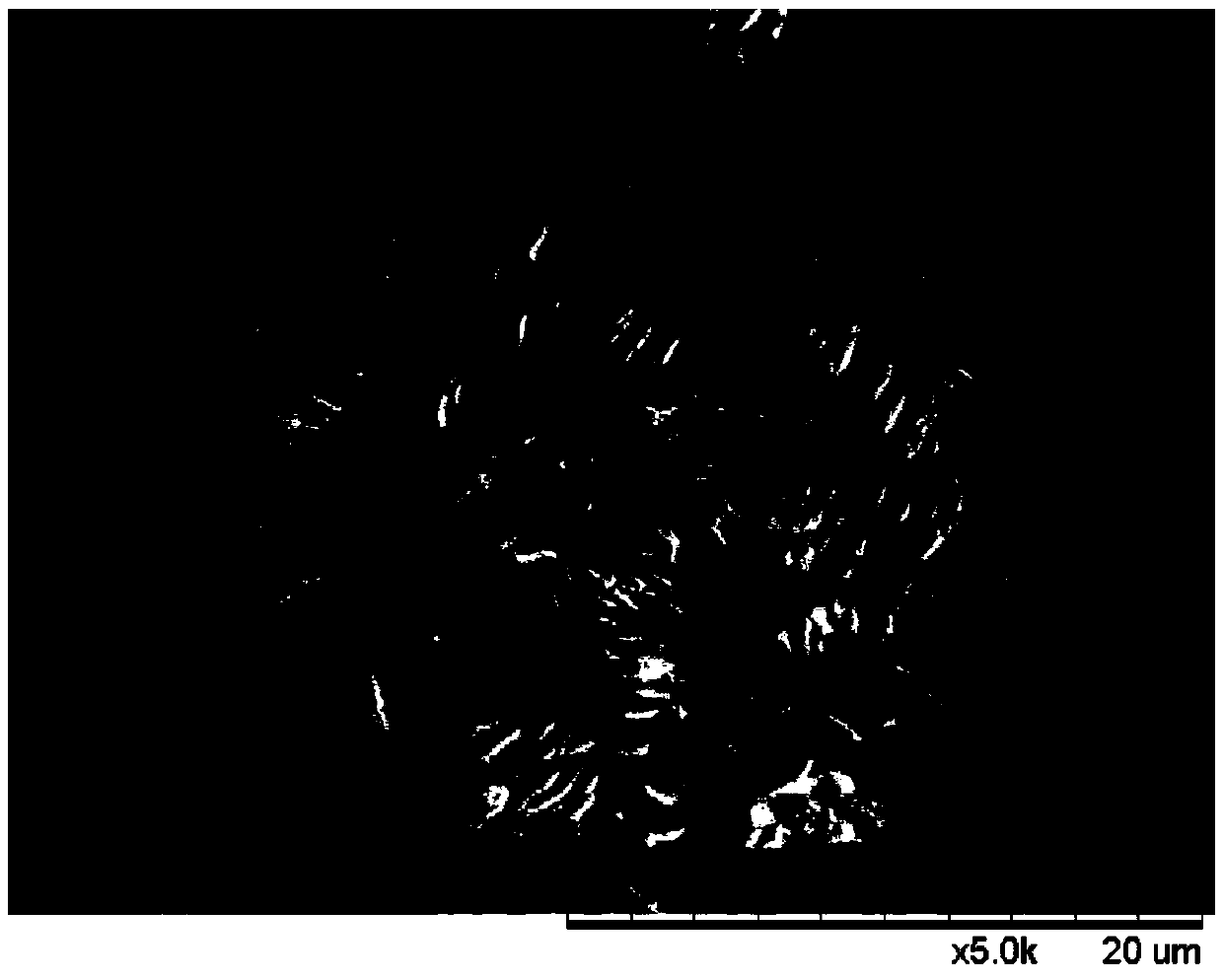

[0038] Finally, the solution was cooled to 0°C according to the cooling rate of 10°C / min until the crystals of the explosive were completely precipitated; filtered, washed with deionized water to remove the surfactant, and dried to obtain the following image 3 The nanoplatelet 1,1-diamino-2,2-dinitroethylene explosive shown.

[0039] The nanosheet 1,1-diamino-2,2-dinitroethylene explosive obtained in this example has a sheet diameter of about 2 μm, a thickness of about 100 nm, and a product purity of 99.4%.

Embodiment 3

[0041] First, weigh 0.05 g of 1,1-diamino-2,2-dinitroethylene and 0.1 g of polyethylene glycol cetyl ether at room temperature, add 100 g of acetone, heat to 50°C, and stir at 300 rpm , so that it completely dissolves into a clear solution;

[0042] Then, the obtained solution was continuously stirred and refluxed at 50°C for 30min;

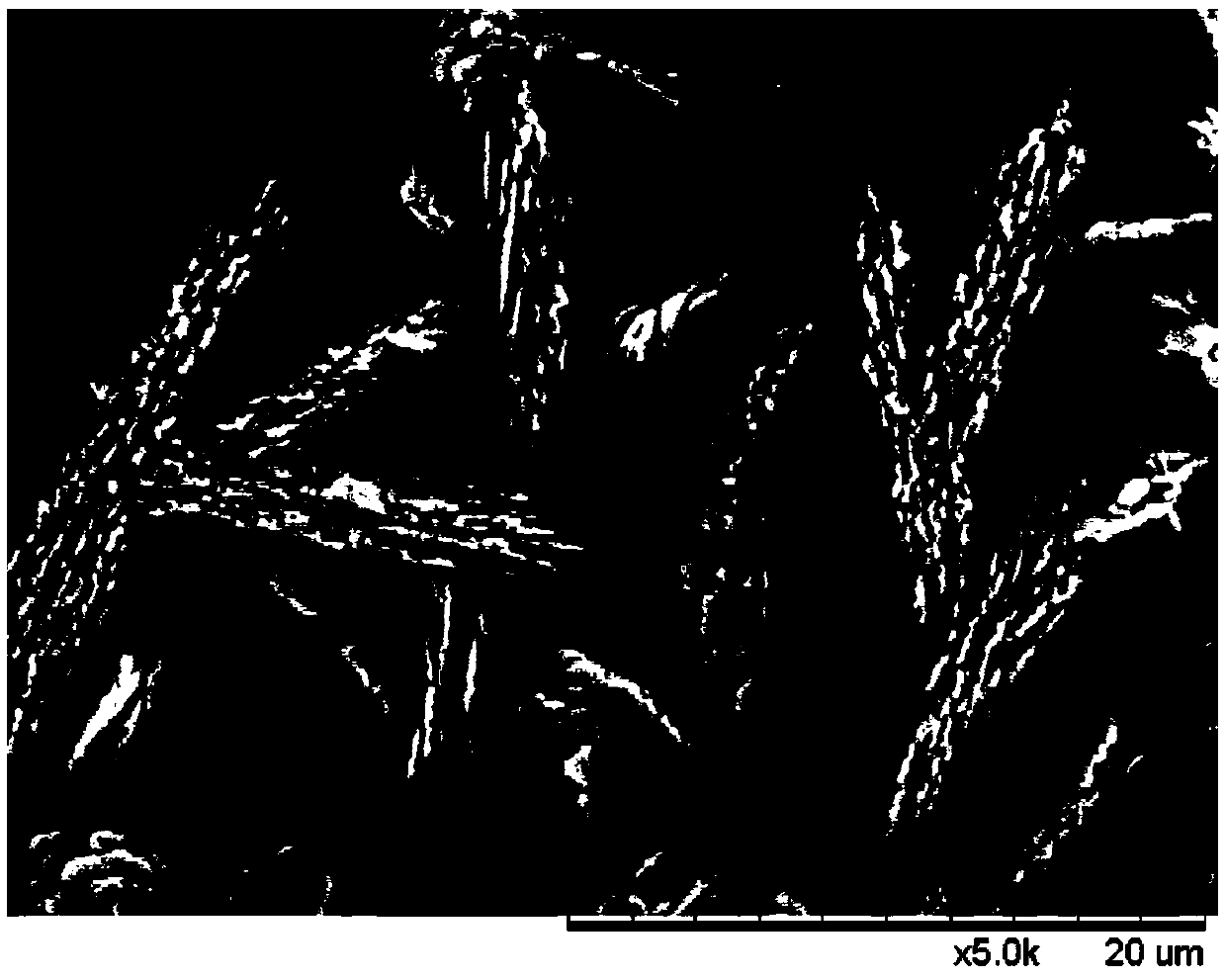

[0043] Finally, the solution is cooled down to 0°C according to the cooling rate of 0.5°C / min until the crystals of the explosive are completely precipitated, filtered, washed with deionized water to remove the surfactant, and dried to obtain the following: Figure 4 The nanoplatelet 1,1-diamino-2,2-dinitroethylene explosive shown.

[0044] The nano-flaky 1,1-diamino-2,2-dinitroethylene explosive sheet layer obtained in this example has a diameter of about 1.5 μm, a thickness of about 100 nm, and a product purity of 99.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com