Preparation process of modified chlorinated polyethylene for rubber plastic material

A chlorinated polyethylene and preparation technology, which is applied in the field of modified chlorinated polyethylene and the preparation technology of modified chlorinated polyethylene, can solve the problem of poor plasticization promotion function, poor durability of low-temperature impact resistance, and poor performance and other issues, to achieve the effect of comprehensive use performance improvement, good use characteristics and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

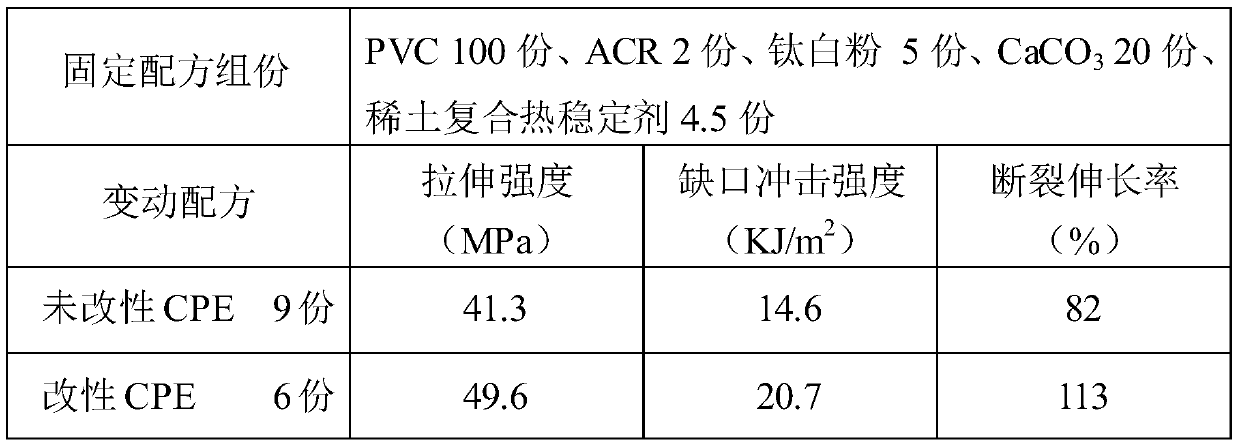

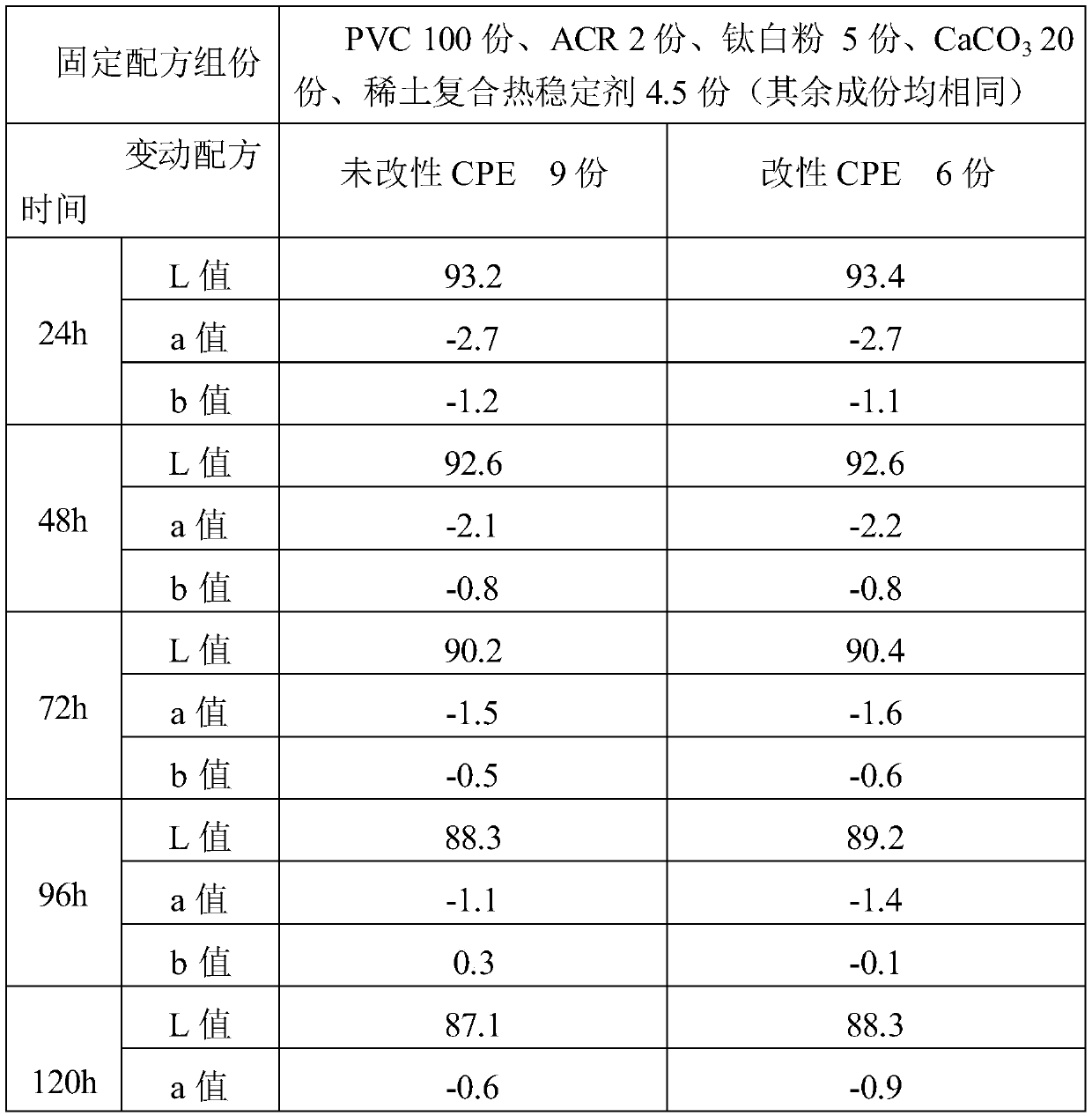

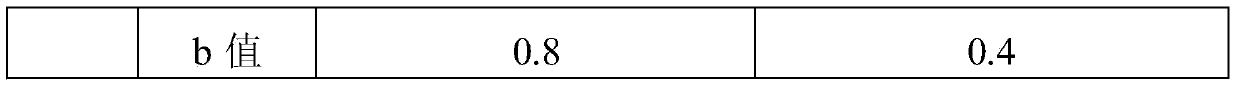

Examples

Embodiment 1

[0030] The chlorinated polyethylene was grafted after swelling with ethyl acetate, including 200 g of chlorinated polyethylene, 35 g of maleic anhydride, 1.2 g of dicumyl peroxide, 100 mL of ethyl acetate, and 1000 mL of deionized water.

[0031] A. Swelling treatment: Add general-purpose chlorinated polyethylene, dicumyl peroxide, maleic anhydride, ethyl acetate and deionized water into the reactor in proportion. The reactor is equipped with a stirrer and a condenser , thermometer, separatory funnel, general-purpose chlorinated polyethylene fully swells for 2 hours when stirred at 60°C;

[0032] B. Dispersion treatment: Add deionized water and dispersant to the product obtained after the swelling treatment in step A for dispersion treatment under stirring, then pass nitrogen into it, raise the temperature to 90°C for reaction for 3 hours, and pump it while it is hot after the reaction During suction filtration, the product is precipitated and separated with a precipitant firs...

Embodiment 2

[0036] The chlorinated polyethylene is grafted after swelling with xylene in water, wherein 250 g of chlorinated polyethylene, 40 g of maleic anhydride, 1.5 g of benzoyl peroxide, 120 mL of xylene, and 1000 mL of water.

[0037] A. Swelling treatment: Add general-purpose chlorinated polyethylene, benzoyl peroxide, maleic anhydride, xylene and deionized water into the reactor in proportion. The reactor is equipped with a stirrer, condenser, and thermometer , Separating funnel, general-purpose chlorinated polyethylene fully swells for 1.5h when stirred at 80°C;

[0038] B. Dispersion treatment: Add deionized water and a dispersant to the product obtained after the swelling treatment in step A for dispersion treatment, then pass nitrogen into it, raise the temperature to 90°C for 3 hours, and carry out separation after the reaction. liquid, separate the xylene, add a precipitating agent to precipitate and separate the product, and wash the product with hot water to obtain a modif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com