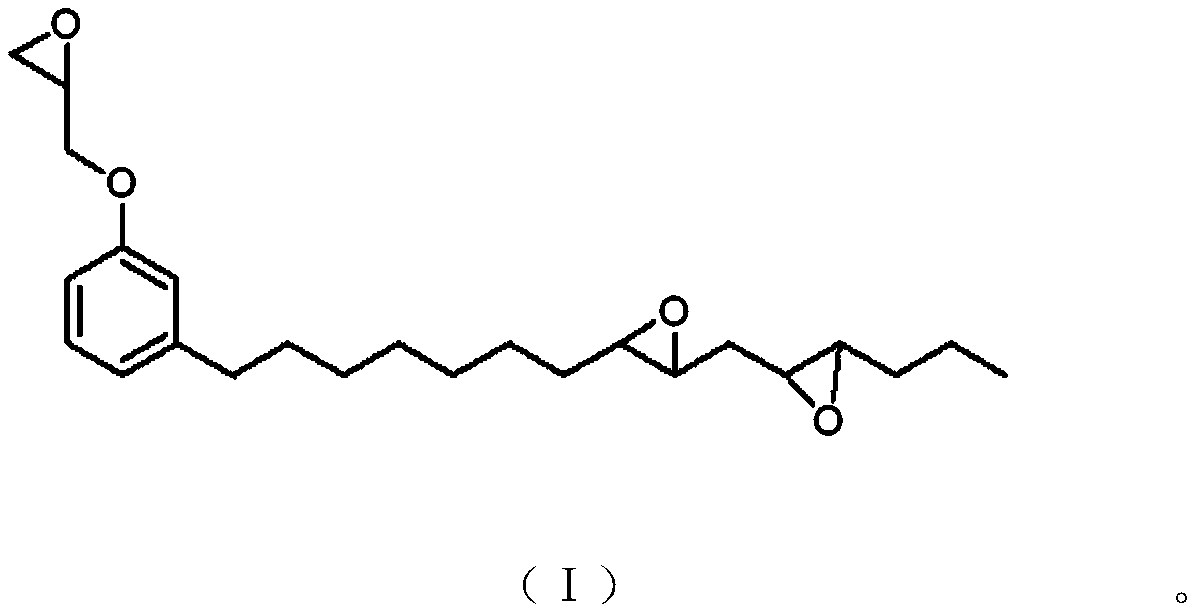

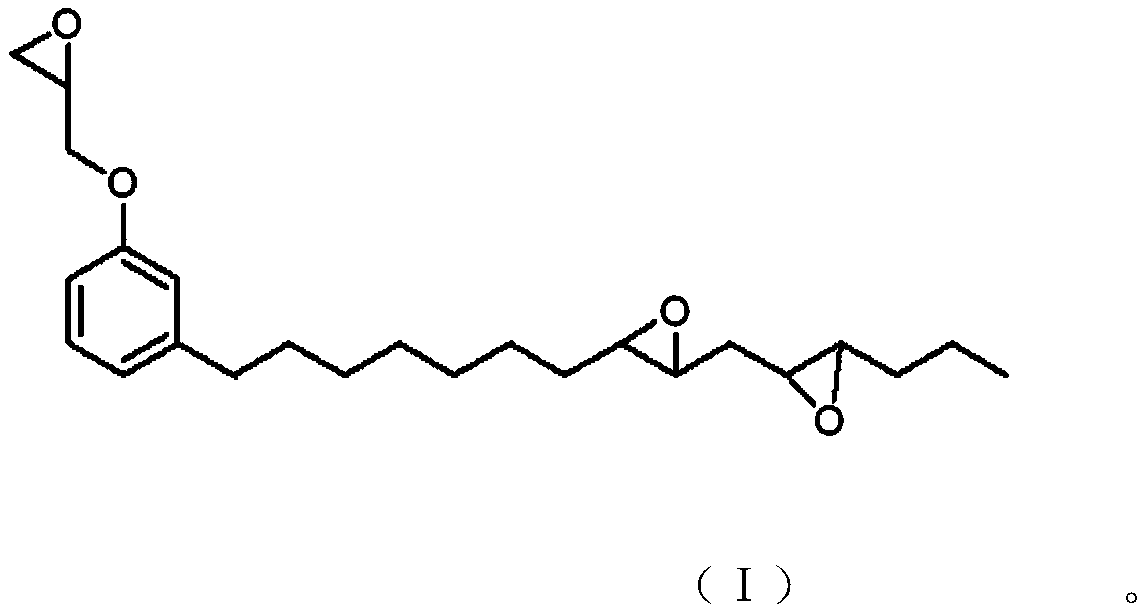

Flexible epoxy resin and preparation method thereof

A technology of flexible epoxy resin and hydrogen peroxide, which is applied in the chemical industry, can solve the problems of brittleness and other problems, and achieve the effects of improving brittleness, good toughness, and obvious technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Weigh 80g of phenol glycidyl ether according to weight, stir 200g of dichloromethane evenly, add 50g of phosphoric acid and 15g of acetic acid while stirring, reflux at room temperature for 30 minutes, then slowly add 140g of hydrogen peroxide (35%), control the temperature within 30°C After reacting for 8 hours, wash with water to neutral extraction, adjust PH to neutral extraction with sodium carbonate, wash twice with deionized water and remove water to obtain product with a calculated yield of 98.2%, epoxy value of 0.211, and film flexural toughness of 1mm , Impact 50cm. Bisphenol A type epoxy resin paint film with the same epoxy value has a toughness of 3mm and an impact of 30cm.

Embodiment 2

[0013] Weigh 80g of cardanol glycidyl ether according to weight, stir 500g of dichloromethane evenly, add 60g of phosphoric acid and 15g of acetic acid while stirring, reflux reaction at room temperature for 30 minutes, then slowly add 160g (35%) of hydrogen peroxide, and control the temperature at 30°C Within 8 hours, wash with water to neutral extraction, use sodium carbonate to adjust PH to neutral extraction, wash twice with deionized water and remove water to obtain a product with a calculated yield of 98.2%, an epoxy value of 0.213, and a paint film with a flexural toughness 1mm, impact 50cm. Bisphenol A type epoxy resin paint film with the same epoxy value has a toughness of 3mm and an impact of 30cm.

Embodiment 3

[0015] Weigh 80g of cardanol glycidyl ether by weight, stir 500g of dichloromethane evenly, add 25g of phosphoric acid and 20g of acetic acid while stirring, reflux reaction at room temperature for 30 minutes, then slowly add 140g (35%) of hydrogen peroxide, and control the temperature at 30°C Within 8 hours, wash with water to neutral extraction, use sodium carbonate to adjust PH to neutral extraction, wash twice with deionized water and remove water to obtain a product with a calculated yield of 98.2%, an epoxy value of 0.221, and a paint film with a flexural toughness 1mm, impact 50cm. Bisphenol A type epoxy resin paint film with the same epoxy value has a toughness of 3mm and an impact of 30cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com